Pneumatic steel wire gauze gun

A steel mesh and pneumatic technology, applied in the field of clamps, can solve the problems of short continuous power supply time, low efficiency and short service life of rechargeable batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The invention will be described in further detail below in conjunction with the accompanying drawings.

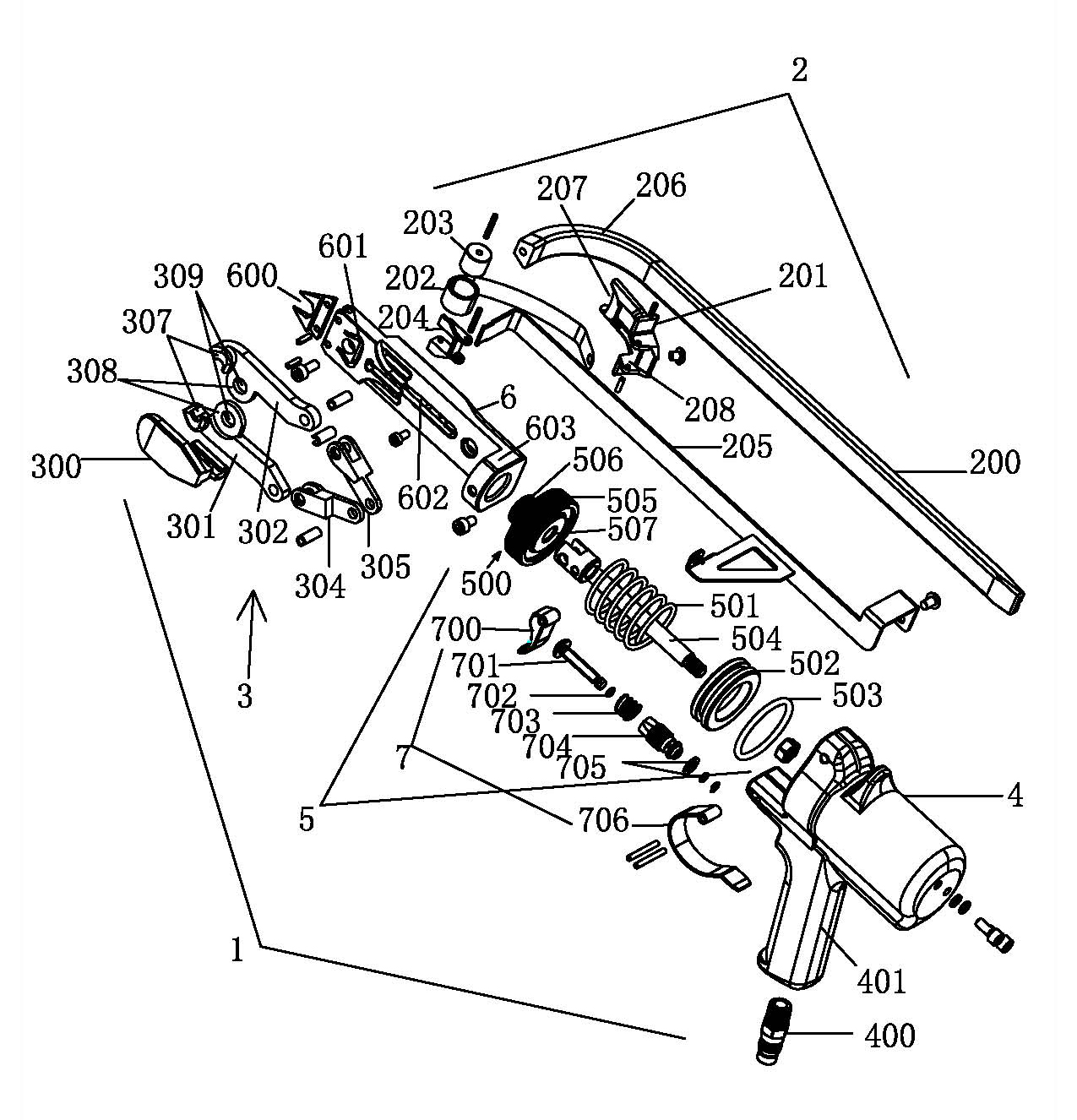

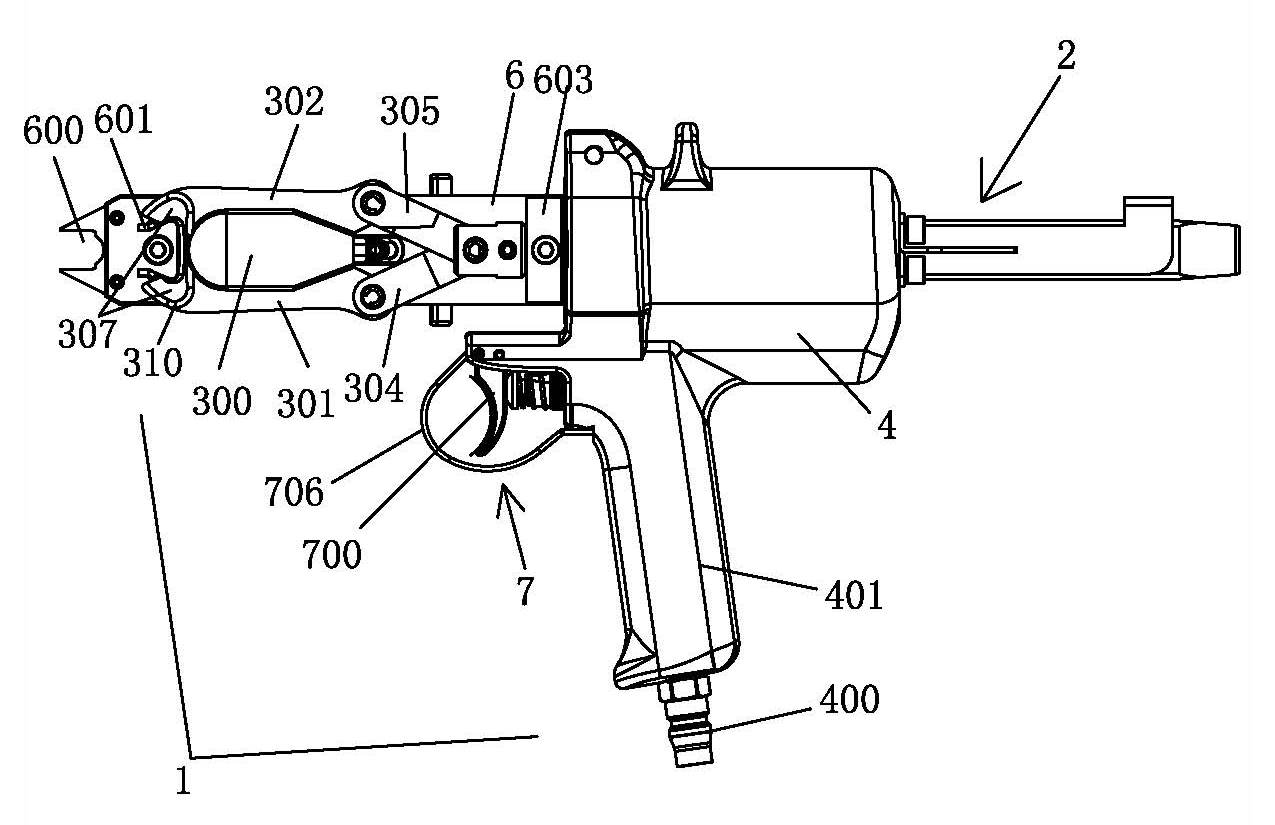

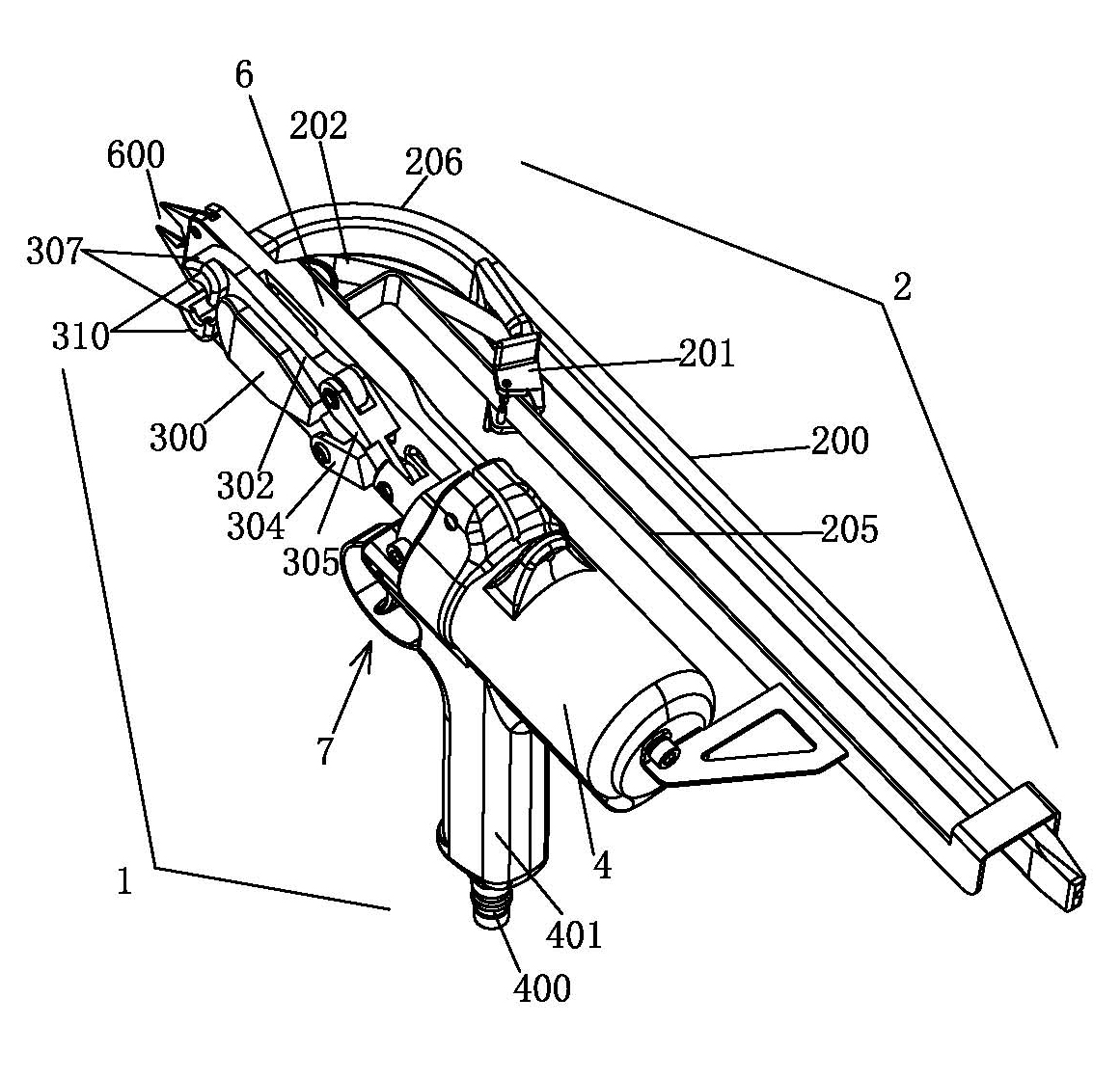

[0031] Such as Figure 1 to Figure 7 As shown, a pneumatic wire mesh gun 1 includes a clamp gun 1 and a nail box 2 .

[0032] Such as Figures 1 to 3 As shown, the clamp gun 1 is mainly composed of a gun frame 6, a gun body 4, a cylinder 5 and a clamp assembly 3 installed on the gun frame 6; the gun body 4 is provided with an air intake chamber, and the cylinder 5 is installed in the air intake chamber , the air intake pipe joint 400 of the air intake chamber stretches out of the gun body 4, and the gun body 4 is also equipped with a switch assembly 7 for controlling the opening or closing of the air intake pipe joint 400. The rear end is provided with the connection block 603 of screw hole, has guide groove 602 on the surface of gun frame 6, and the rear end of gun frame 6 is connected with the cylinder 5 front end that is installed in the gun body 4, and the pist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com