Three-dimensional printer extrusion head capable of feeding in switching mode

A technology of 3D printers and extrusion heads, applied in the field of 3D printers, can solve problems such as mechanical positioning errors, increase costs, increase the weight of extrusion head components, etc., achieve constant feeding friction, avoid mechanical positioning errors, and stabilize feeding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

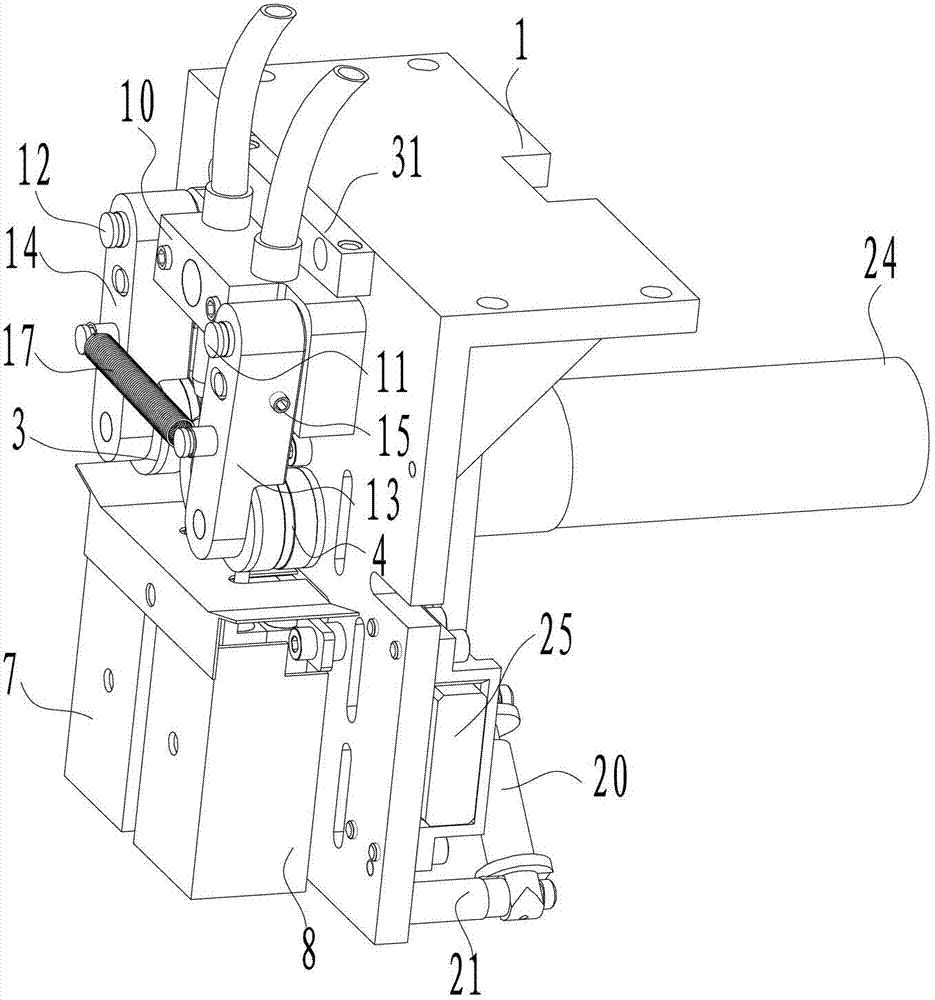

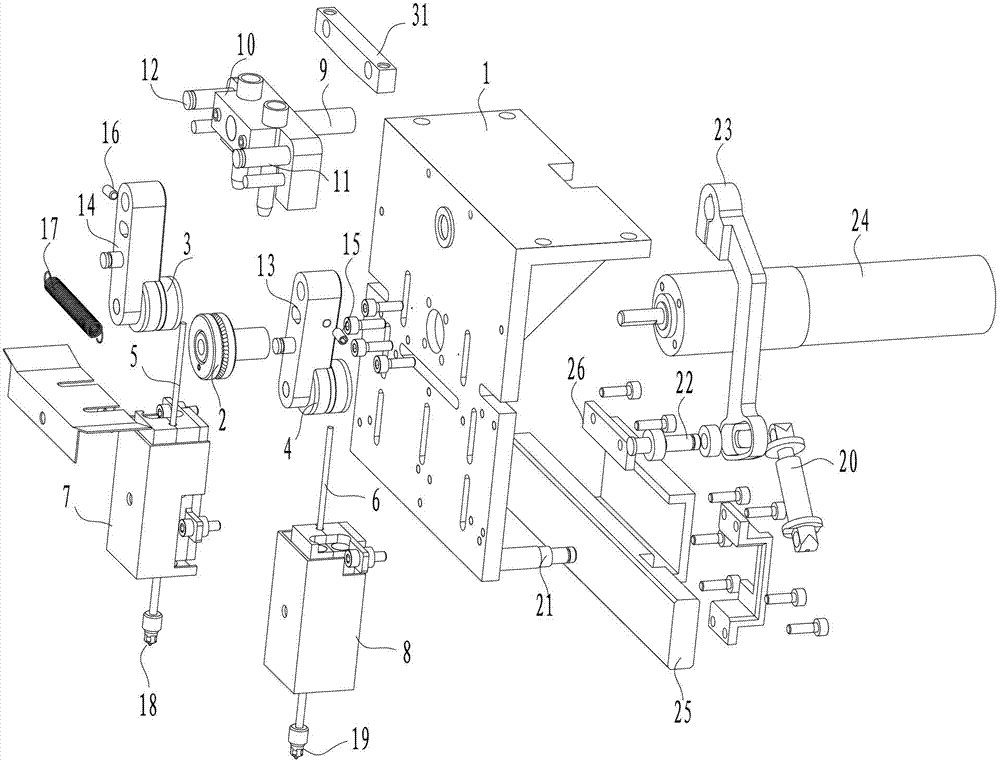

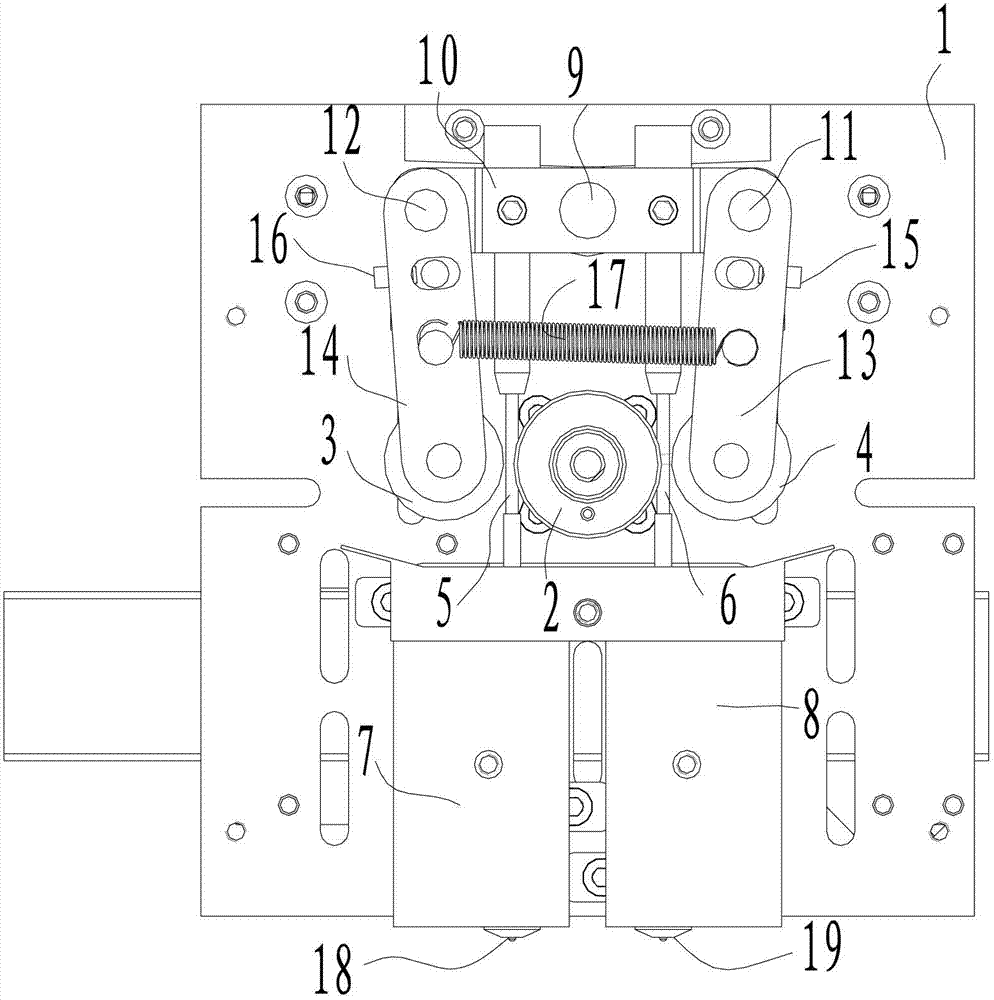

[0023] See Figure 1 and figure 2As shown, a three-dimensional printer extrusion head with switchable feeding includes a base 1, feeding switching components (3, 4, 10, 11, 12, 13, 14, 15, 16,), and feeding switching components pass through the first A rotating shaft 9 is rotatably connected with the base 1, and the passive feeding pressure rollers (3, 4) of the feeding switching assembly are respectively arranged on both sides of the active feeding wheel 2; the front part of the base 1 is equipped with a printing filament heating and melting flow channel ( 7, 8), one end of which is respectively connected to the printing filament (5, 6), and the other end is respectively connected to the printing filament extrusion nozzle (18, 19), and the printing filament (5, 6) is respectively pressed on the passive feeding roller (3, 4) and between the active feeding wheel 2;

[0024] It includes a wire driving motor 24 installed on the back of the base 1, the active feeding wheel 2 dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com