Aquaculture robot

A controller and task planning technology, applied in the control field of automatic material control, automatic feeding, automatic driving, and automatic operation, can solve the problems of waste of bait, high production cost, and thrown bait, so as to reduce the excessive dependence on labor and improve the The effect of water carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

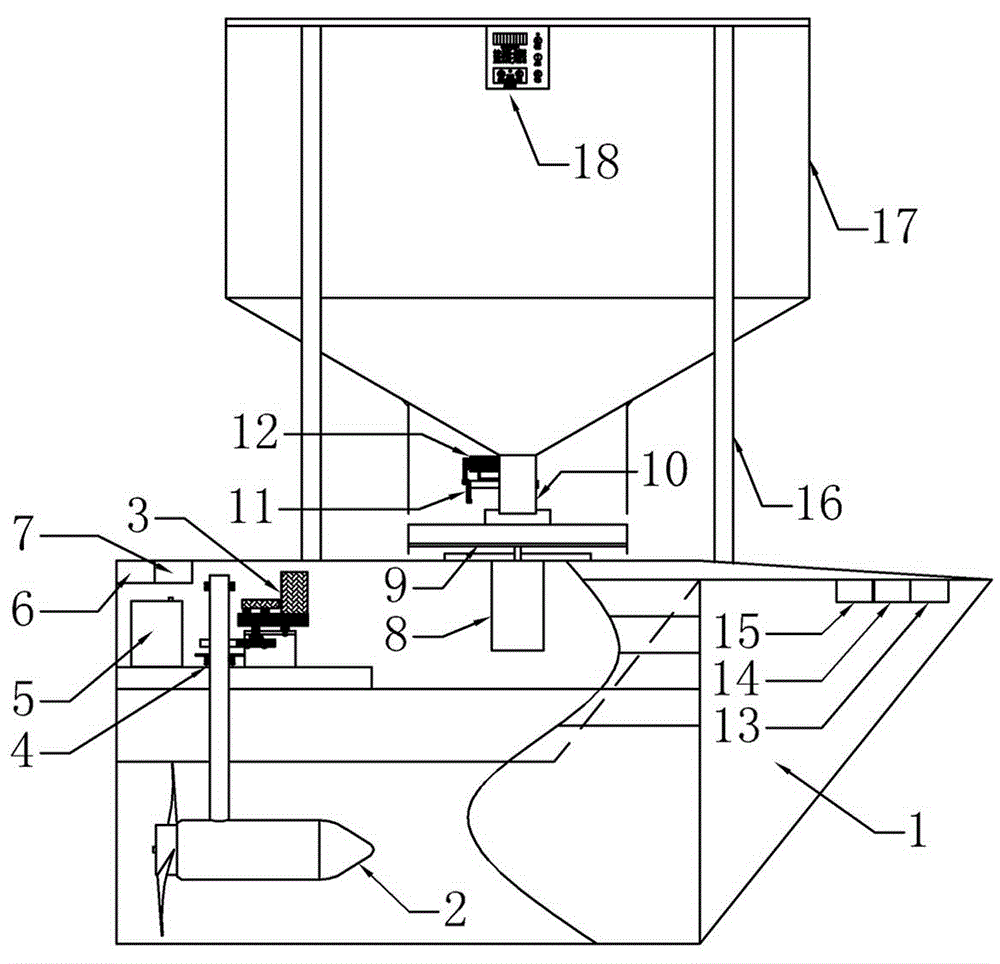

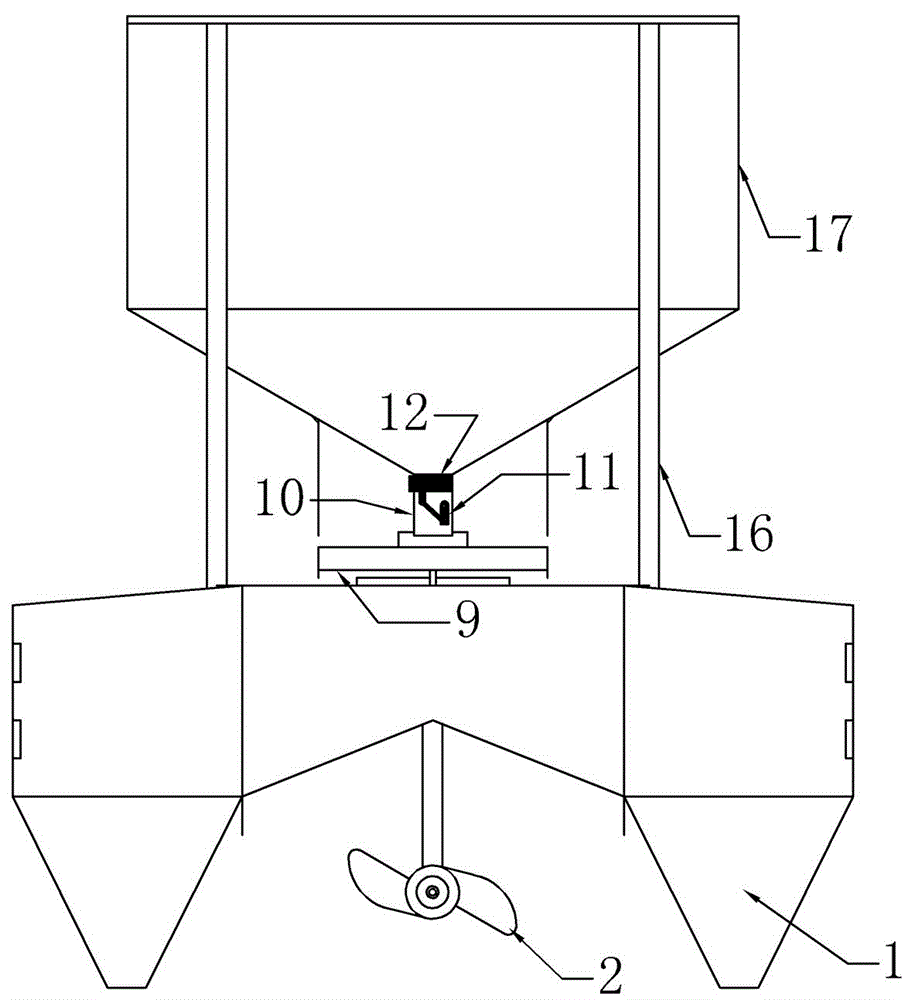

[0006] The present invention implements a fixed route through real-time dynamic control to ensure feeding at a fixed location (fixed area), and implements uniform feeding through real-time dynamic feeding rate control to ensure a fixed quantity at each point. The navigation controller 6 accepts the instructions of the ground station, the remote controller or the shipboard control panel 18, and executes the remote control or automatic mode to control the steering machine 3 to change the course of the hull 1, and to control the propeller 2 to change the speed of the hull 1, and the automatic mode follows the preset route. With the position given by the GPS receiving module 13, no one independently completes the planned mission navigation; according to the real-time voyage and speed sent by the navigation controller 6, the bait feeding controller 7 calculates the real-time amount of material in the hopper 17 through the strain detection support rod 16 The parameters control the fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com