Automatic assembly and detection equipment for magnetic shoe products

A technology for automatic assembly and testing equipment, applied in mechanical equipment, measuring devices, devices for coating liquid on surfaces, etc., can solve the problems of high scrap rate, efficiency and accuracy that cannot be achieved manually, and low assembly accuracy and yield rate, etc. achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

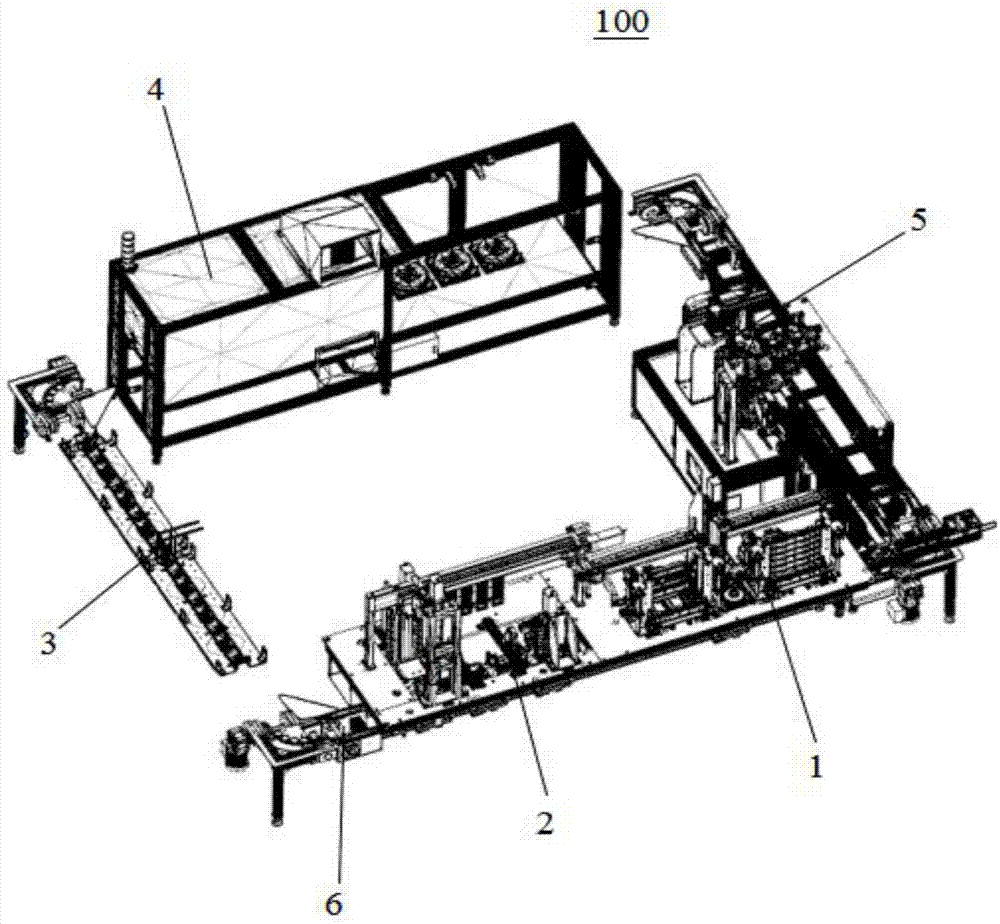

[0039] Please refer to figure 1 , this embodiment is an automatic assembly and testing device 100 for magnetic tile products, which includes a magnetic tile pre-installation positioning mechanism 1, a magnetic tile dispensing assembly mechanism 2, a baking chamber 3, a cooling chamber 4, a detection and blanking mechanism 5, and runs through all of the above The automatic conveying device 6 of the mechanism and the tooling 7 moving on the automatic conveying device 6 .

[0040] Automatic conveying device 6 is positioned at the below of above-mentioned all mechanisms.

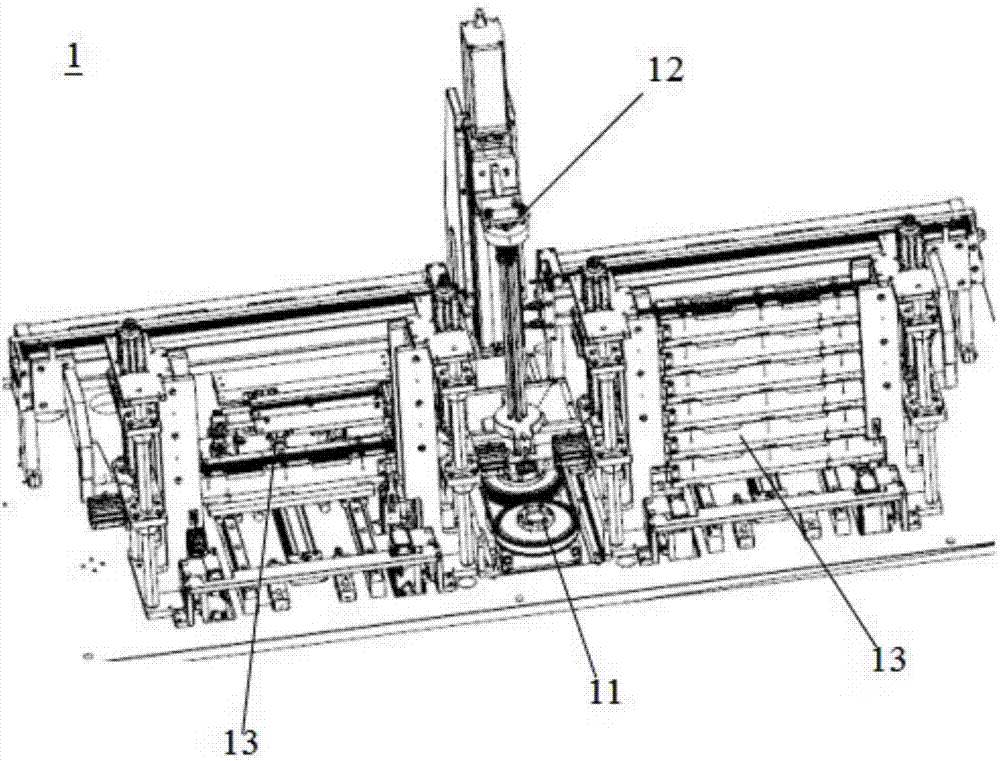

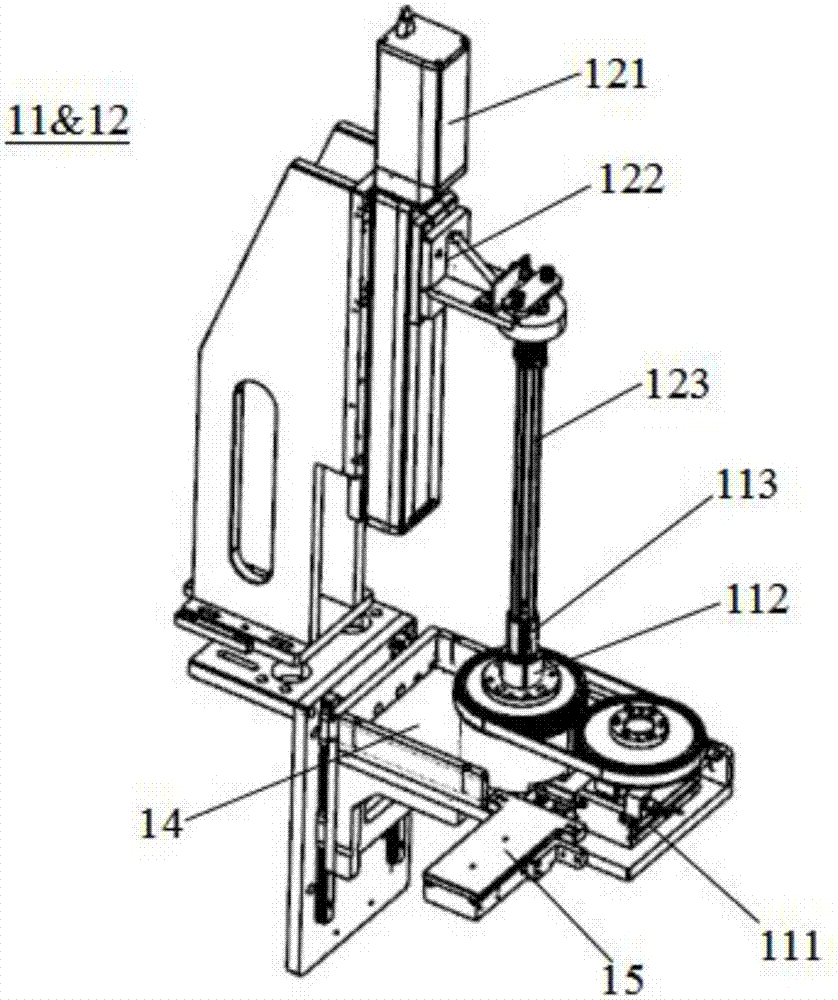

[0041] Please refer to figure 2 The magnetic tile pre-installation positioning mechanism 1 includes a magnetic tile loading unit 11 that loads a plurality of magnetic tiles at an equal angle, a magnetic tile pressing unit 12 that presses the magnetic tiles from the magnetic tile loading unit 11 up and down onto the tooling 7, and is symmetrically arranged on the magnetic tile. Magnetic tile feeding and loadin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com