Circuit board assembly detection system

A detection system and circuit board technology, applied in electronic circuit testing, printed circuit, printed circuit manufacturing and other directions, can solve the problems of slow manual placement of digital tubes, spraying ink everywhere, and increasing production costs of enterprises. Shorten the production cycle, reduce labor costs, and improve the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

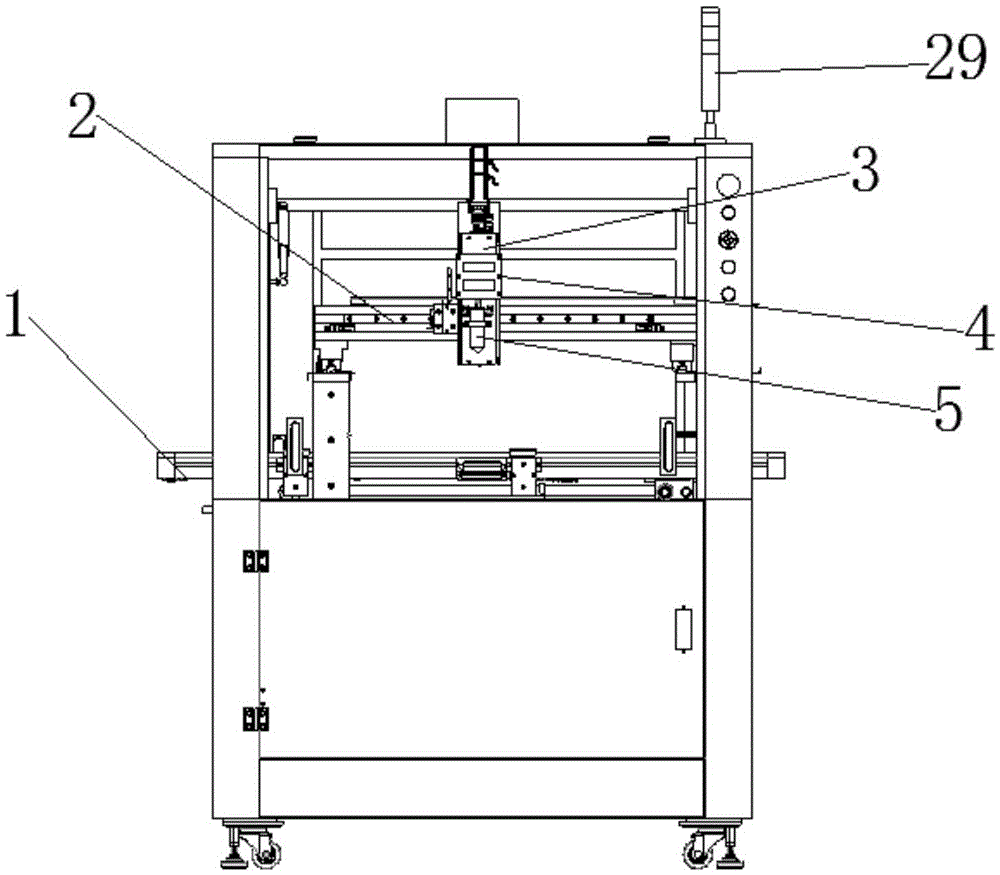

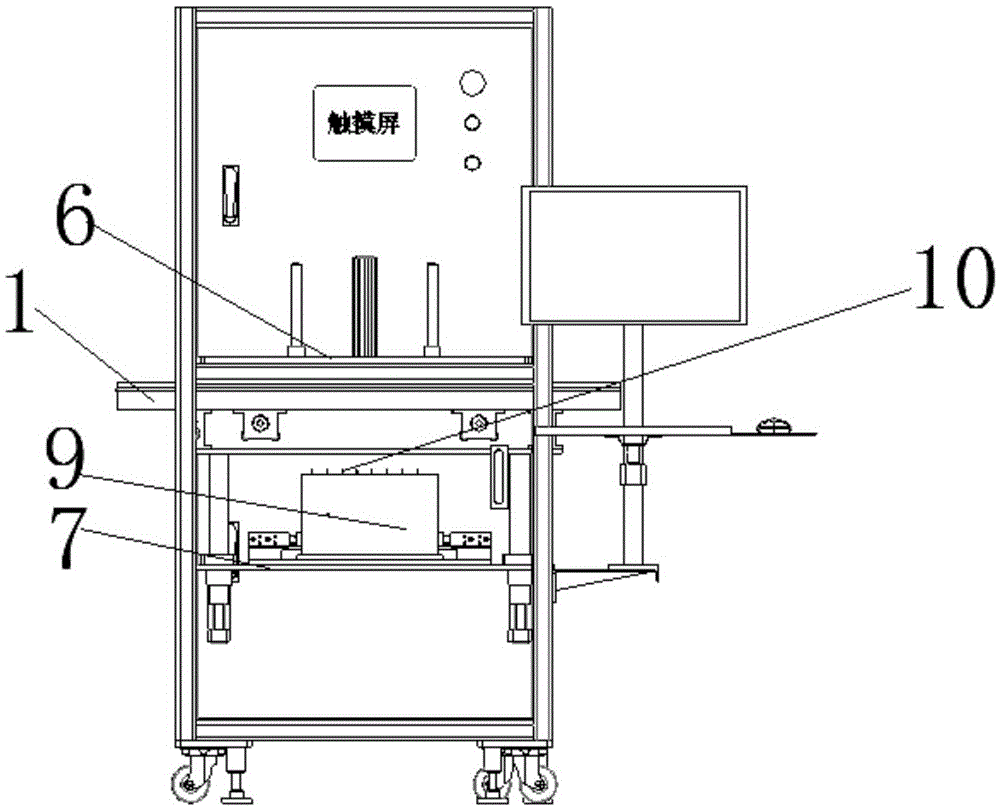

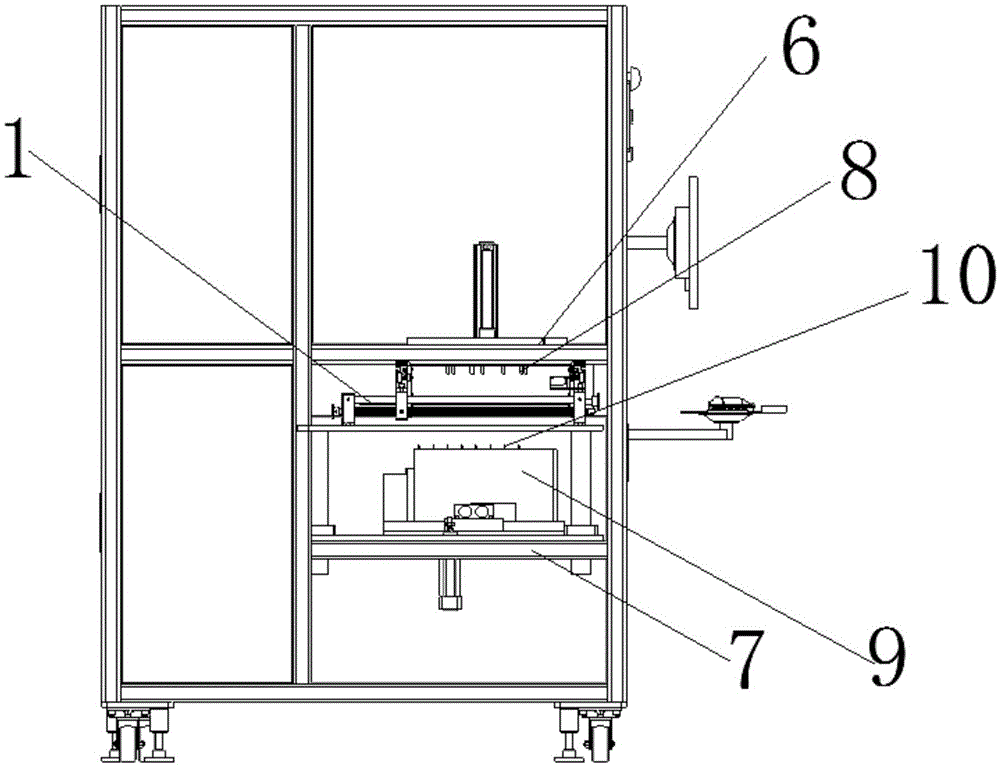

[0030] As shown in the figure, the circuit board assembly detection system includes a transmission device 1, and along the transmission direction of the transmission device 1, there are coding equipment, ICT testing equipment, digital tube insertion equipment, FCT testing equipment, CCD scanning equipment and fuel injection equipment in sequence. , the transmission device 1 can be belt transmission, chain transmission, etc. When the system is in use, it can automatically perform coding operation, ICT test, digital tube insertion, FCT test, digital tube function detection, and oil injection operation on the circuit board in sequence. These operations are completed on the same assembly line, the machine replaces the worker and liberates manpower.

[0031] The coding equipment includes a first casing and a control processor installed on the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com