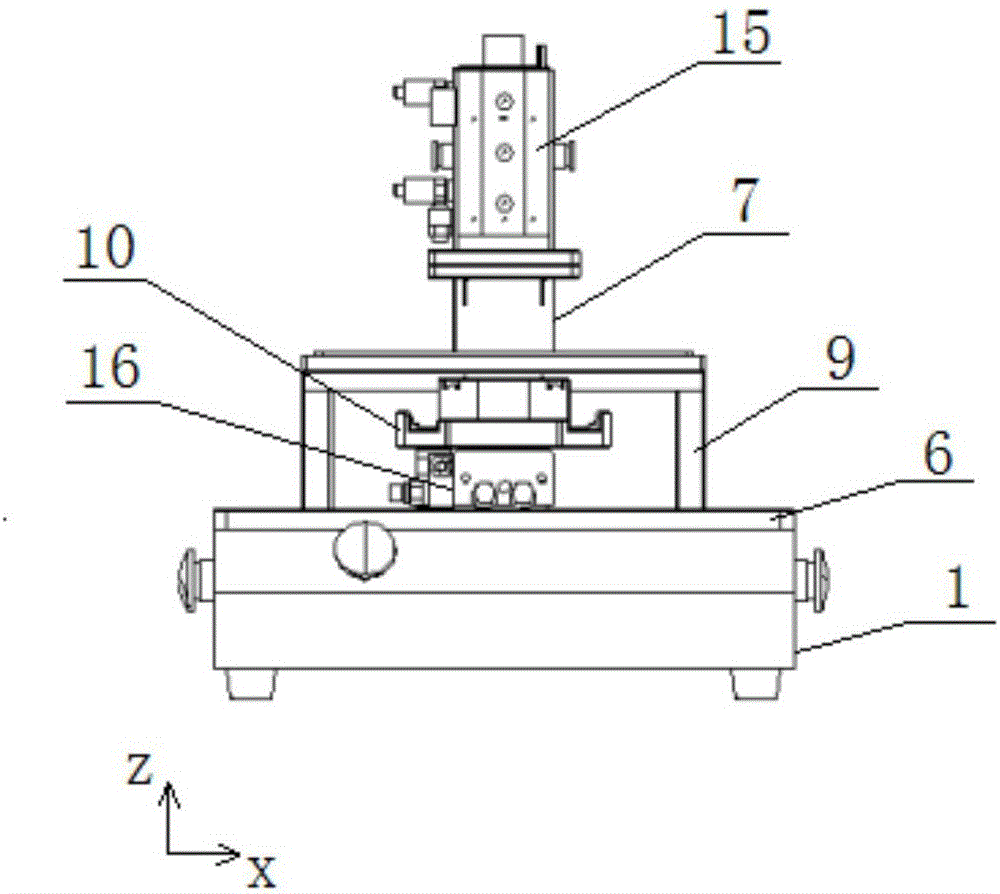

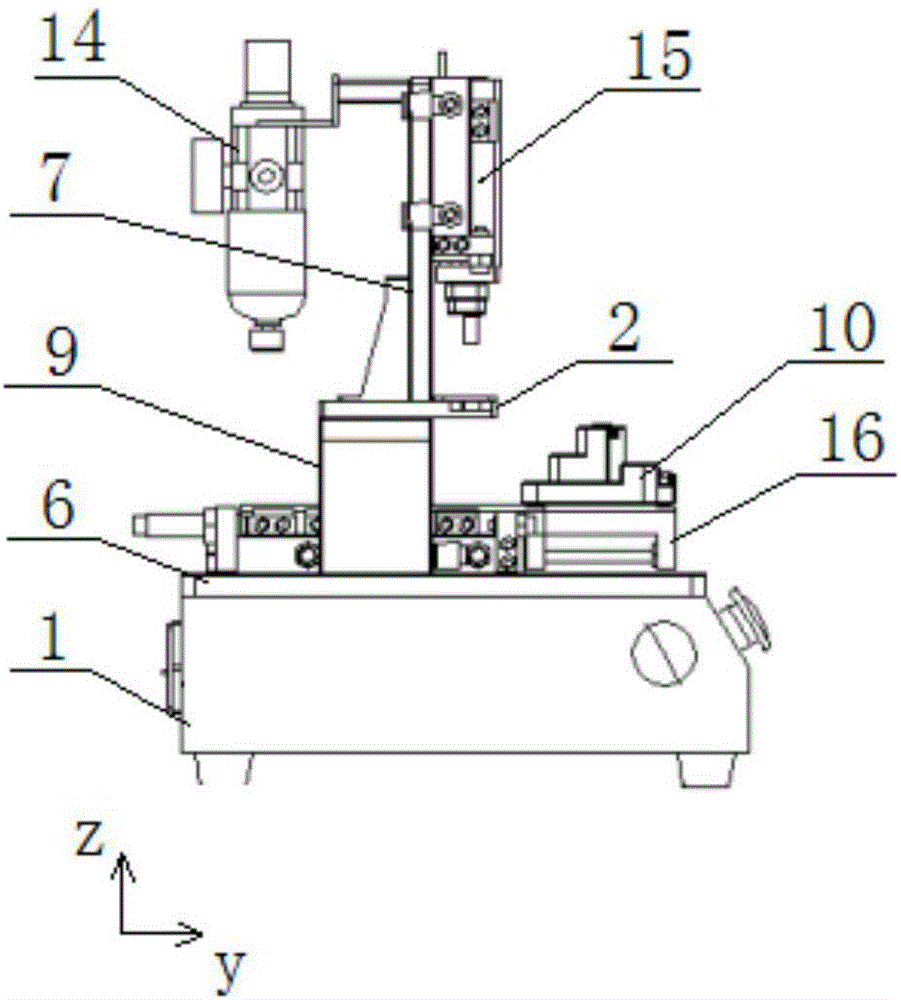

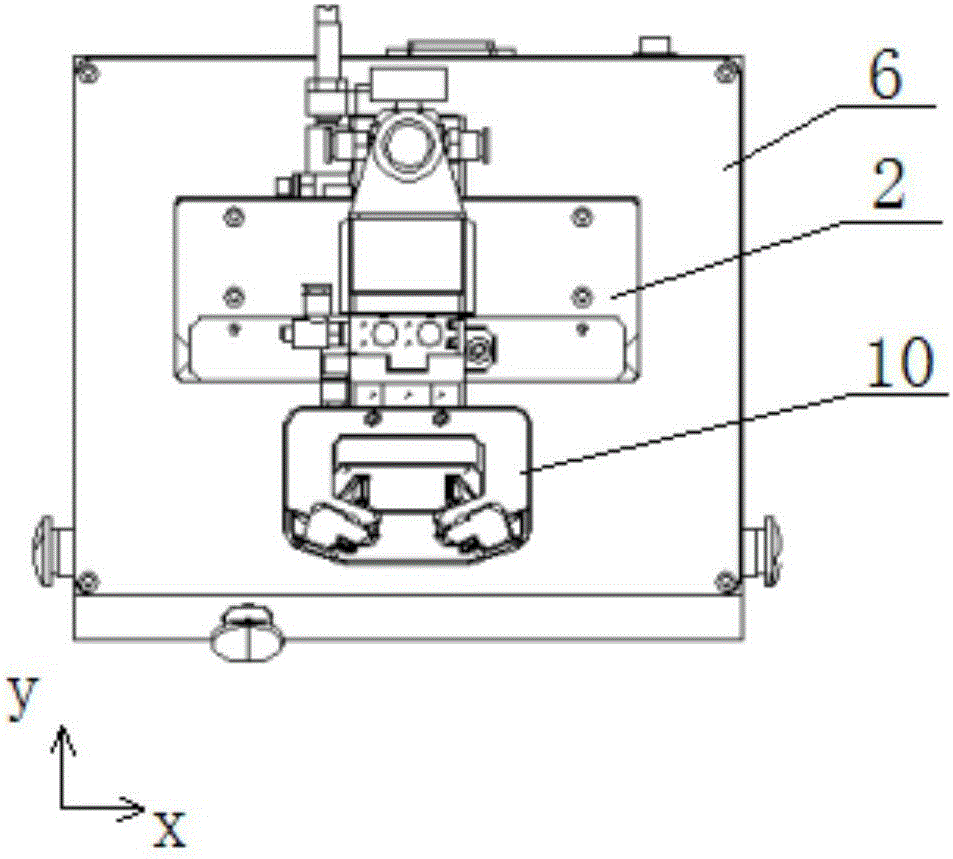

Semi-automatic magnet assembly tool

A semi-automatic, magnet technology, applied in manufacturing tools, metal processing equipment, metal processing, etc., can solve problems such as poor operation, reverse magnet installation, slow operation speed, etc., achieve low processing cost, increase operation speed, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The existing technology of product magnet assembly is: generally manual assembly, the operation speed is slow, and the phenomenon that the magnet is installed in reverse is prone to occur, resulting in poor operation.

[0025] The design concept of the present invention is: aiming at manual magnet assembly, the operation speed is slow, and the phenomenon of reverse magnet installation is easy to occur, resulting in poor operation. In the present invention, a trough for placing magnets is set on the magnet placement seat, and a fixed trough is designed in the middle to place and fix magnet materials, and the placement direction is placed according to the requirements of the assembly process; a row of magnets put into the trough fixes the suction force of the magnets here Under the action, it moves forward, and finally adsorbs to the side wall of the innermost trough. Under the side wall, there is a magnet guide groove for installing magnets into the product. After the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com