Lamp holder assembly equipment

A technology for assembling equipment and lamp caps, which is applied in the direction of assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of high labor cost and low assembly efficiency, and achieve the effects of low cost, simple structure and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

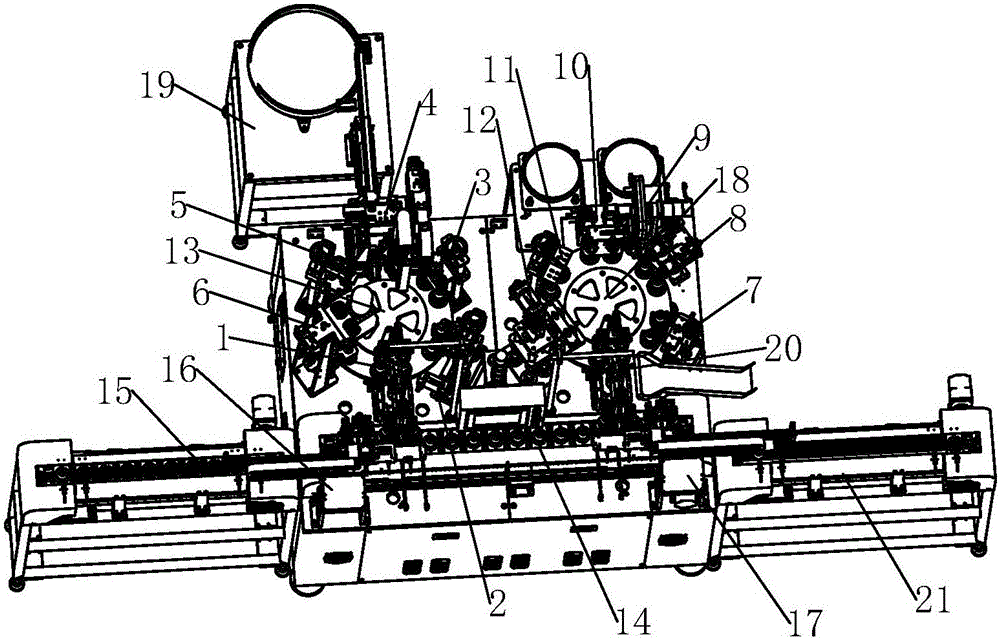

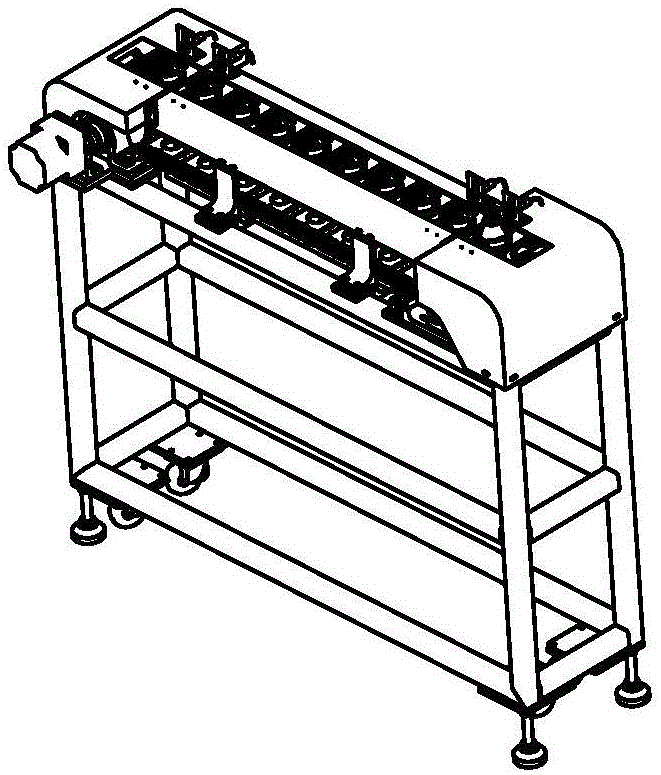

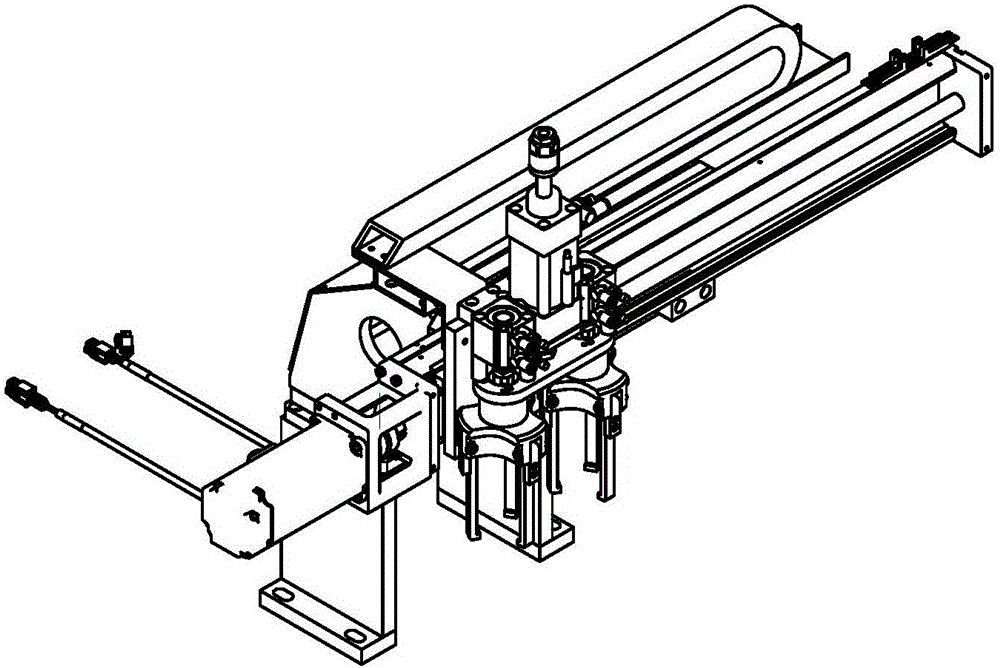

[0034] Please refer to Figure 1-Figure 17 , the present invention provides a lamp cap assembly equipment, comprising: a first connecting conveying chain mechanism 15; a feeding manipulator 16, which is used to grab and move the workpiece on the first connecting conveying chain mechanism 15 to the conveying chain driving mechanism 14 Above: the first rotary feeding mechanism 1 is used to move the workpiece from the conveyor chain transmission mechanism 14 to the first turntable mechanism 13, and the first turntable mechanism 13 is sequentially provided with a live line correction mechanism for processing the workpiece on the rotation path 2. Lamp holder correction mechanism 3, screw assembly mechanism 4, screw pressure positive mechanism 5 and screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com