Press-casting multi-bottom pan and press-casting forming manufacturing process

A technology of die-casting and double-bottom pots, which is applied to special materials for cooking utensils, cooking utensils, household appliances, etc., and can solve problems such as high production costs, poor positioning reliability, and affecting service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below with reference to the accompanying drawings and examples.

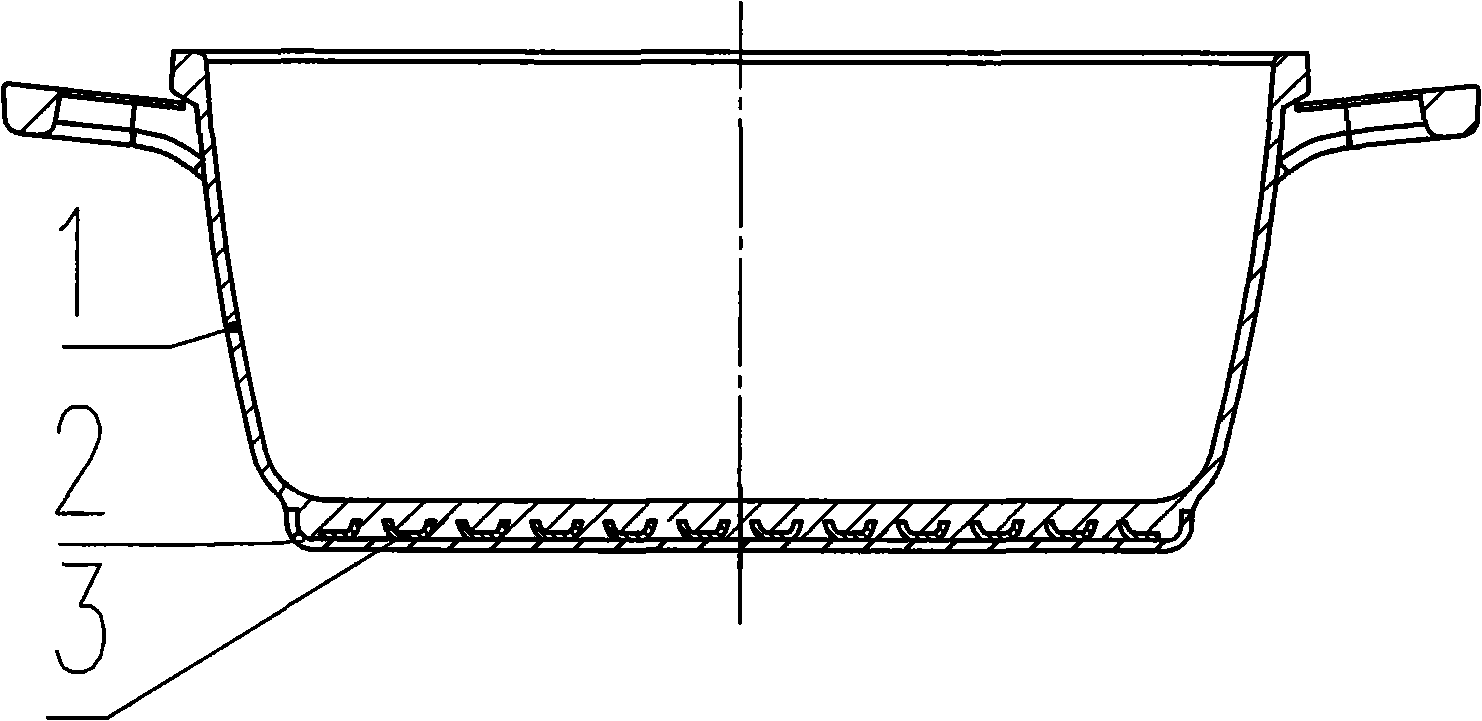

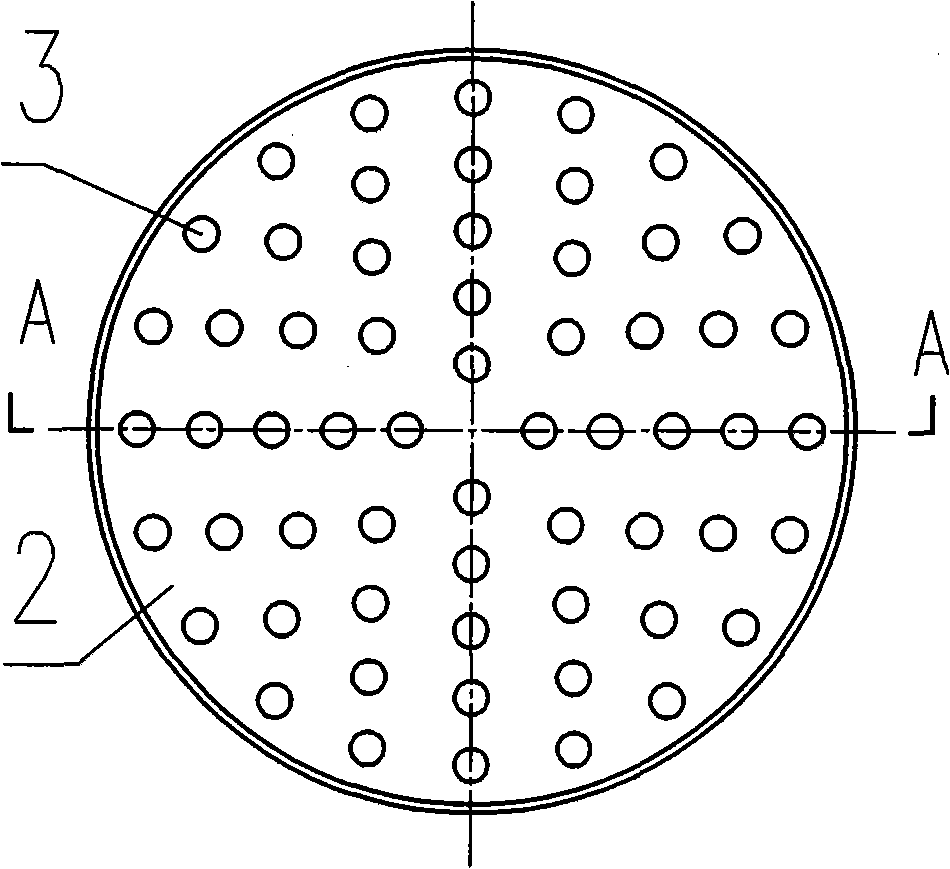

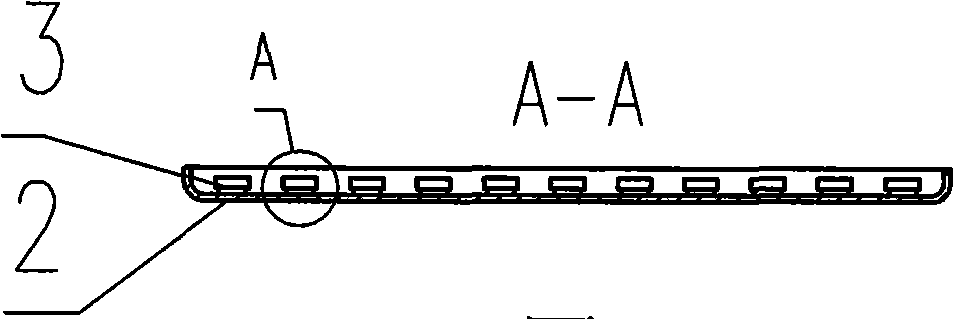

[0026] refer to figure 1 , the die-cast double-bottom pot includes an aluminum alloy pot body 1 and a stainless iron double-bottom sheet 2, a number of clips 3 are welded on the stainless-iron double-bottom sheet 2, and the periphery of the stainless-iron double-bottom sheet 2 forms a flanging covering the periphery of the lower part of the pot body , the lower part of the aluminum alloy pot body 1 and the stainless iron complex negative plate 2 are die-cast into one body through a die-casting machine. refer to Figure 2 ~ Figure 4 , The clip 3 is in the shape of a stud, and can be welded on the stainless iron composite negative 2 regularly or irregularly. refer to Figure 5 ~ Figure 7 , The clamping part 3 is welded on the stainless iron compound negative sheet 2 for mesh shape. refer to Figure 8 ~ Figure 10 , The clip 3 is a hole edge shape, which ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com