Aluminium alloy compression casting pan with compound bottom and compound technique thereof

A composite process, aluminum alloy technology, applied in special materials for cooking utensils, cooking utensils, household appliances, etc., can solve the problems of small effective area, surface damage of induction cooker, and insufficient flatness of film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below with reference to the accompanying drawings and examples.

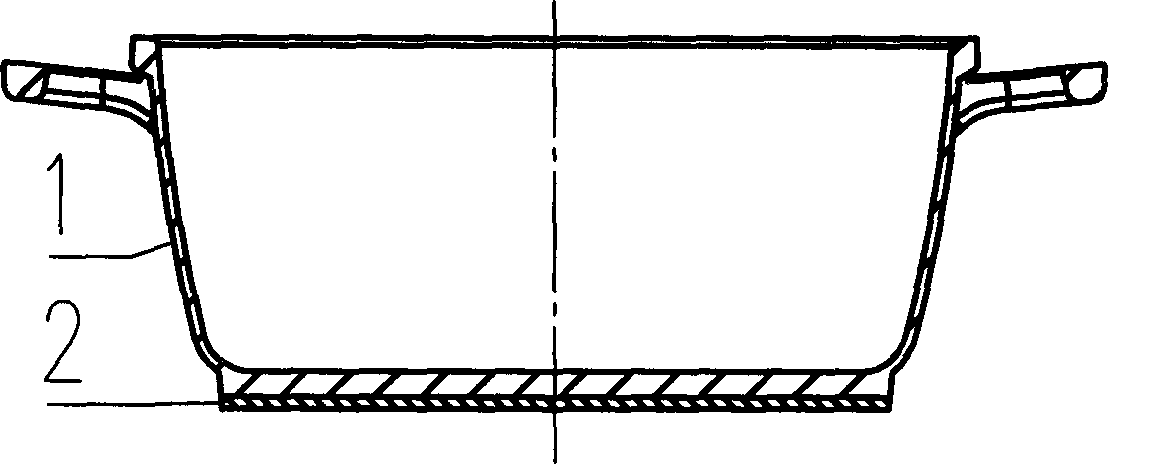

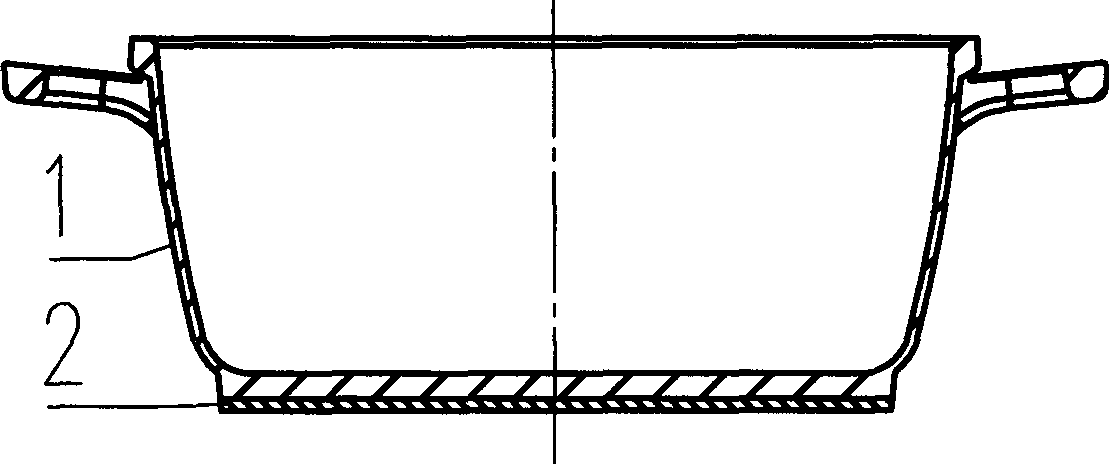

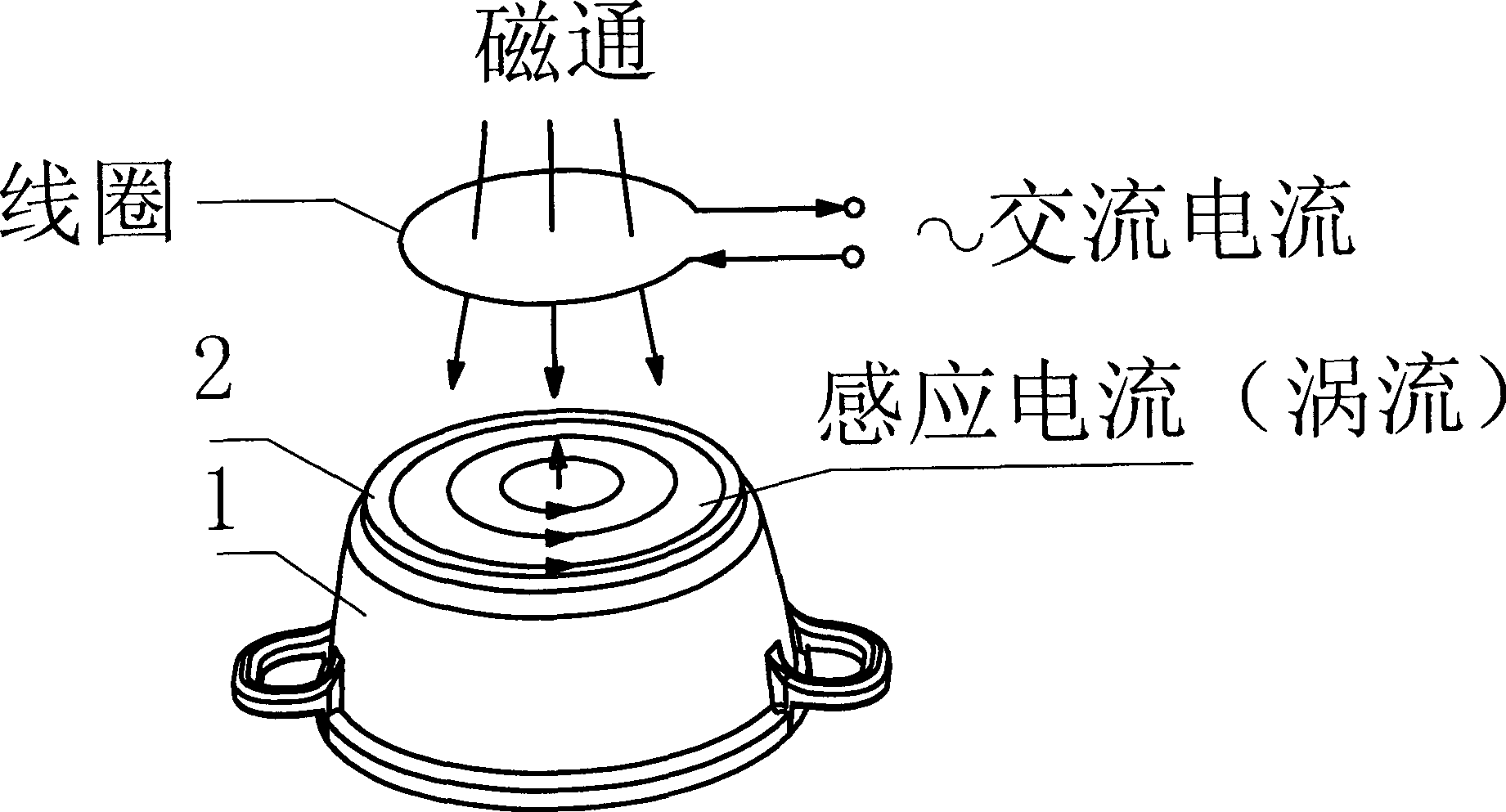

[0019] Referring to Fig. 1, the aluminum alloy die-casting pot with a composite bottom includes an aluminum alloy die-casting pot body 1 and a stainless iron compound base 2, and the stainless iron compound base 2 is directly laminated and composited with the pot body 1 as a whole. 2 on. Referring to Fig. 2, the aluminum alloy die-casting pot with composite bottom can be manufactured by the following process: first, the aluminum alloy die-casting pot body 1 is die-casted on a die-casting machine; then the surface of the pot body is cleaned; Apply the compounding agent; then put the bottom of the aluminum alloy die-casting pot body upside down, and then stick the side of the stainless iron film coated with the compounding agent on the bottom of the pot body; The rusty iron complex film is pressed tightly on the bottom of the pot, and the pressing pressure va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com