Aluminum pot and new double-bottom process thereof

A technology of aluminum pots and double negatives, which is applied to special materials for cooking utensils, cooking utensils, household utensils, etc., can solve the problems of low heat fatigue resistance, high production cost, and low connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

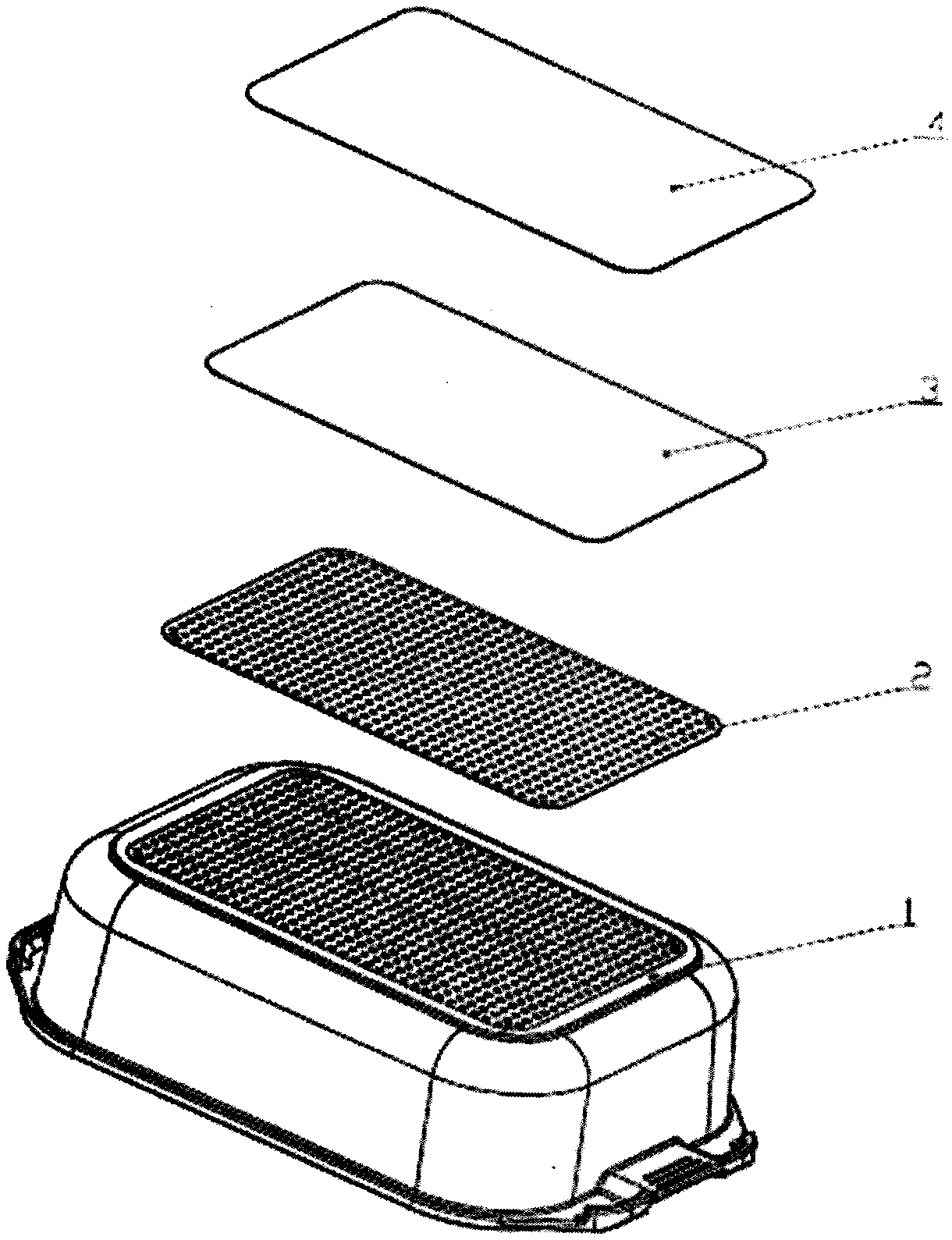

[0017] Such as figure 1 As shown, an aluminum pot includes an aluminum alloy pot body 1 and a composite base 2. Its main feature is that the composite base 2 is provided with a number of small holes, and an aluminum foil 3 is also arranged above the porous composite base 2. The above-mentioned aluminum foil 3 is provided with a non-porous composite bottom sheet 4, and the lower part of the aluminum alloy pot body 1 and the porous composite bottom sheet 2 are riveted into one body through a hydraulic press. Welding machine high temperature brazing into one;

[0018] The several small holes can be of any shape;

[0019] The main component of the porous composite negative sheet 2 and the non-porous composite negative sheet 4 is iron;

[0020] The new double-bottom process of the above-mentioned aluminum pan. The compound bottom process includes the following steps:

[0021] (1) Pressure riveting the perforated bottom sheet 2 on the pot body 1 with a hydraulic press;

[0022]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com