Stabilizing Tray For Shipping and Display Stacked Containers

a technology for displaying containers and trays, which is applied in the field of trays for shipping containers, can solve the problems of increased labor and cost for retailers, increased cost for shipping and storing carts and crates, and shelf space, and achieves neat and stable display, easy to make and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

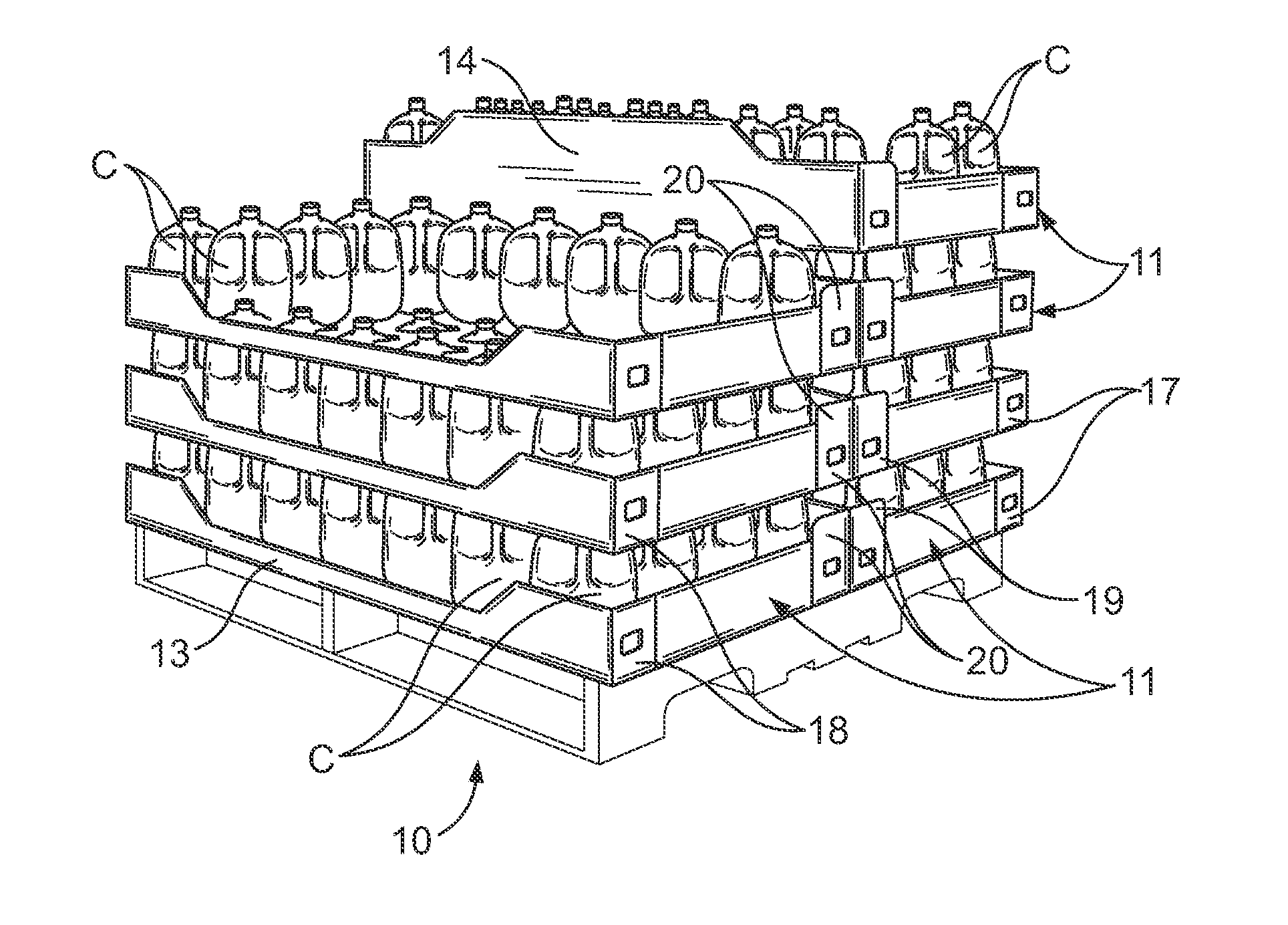

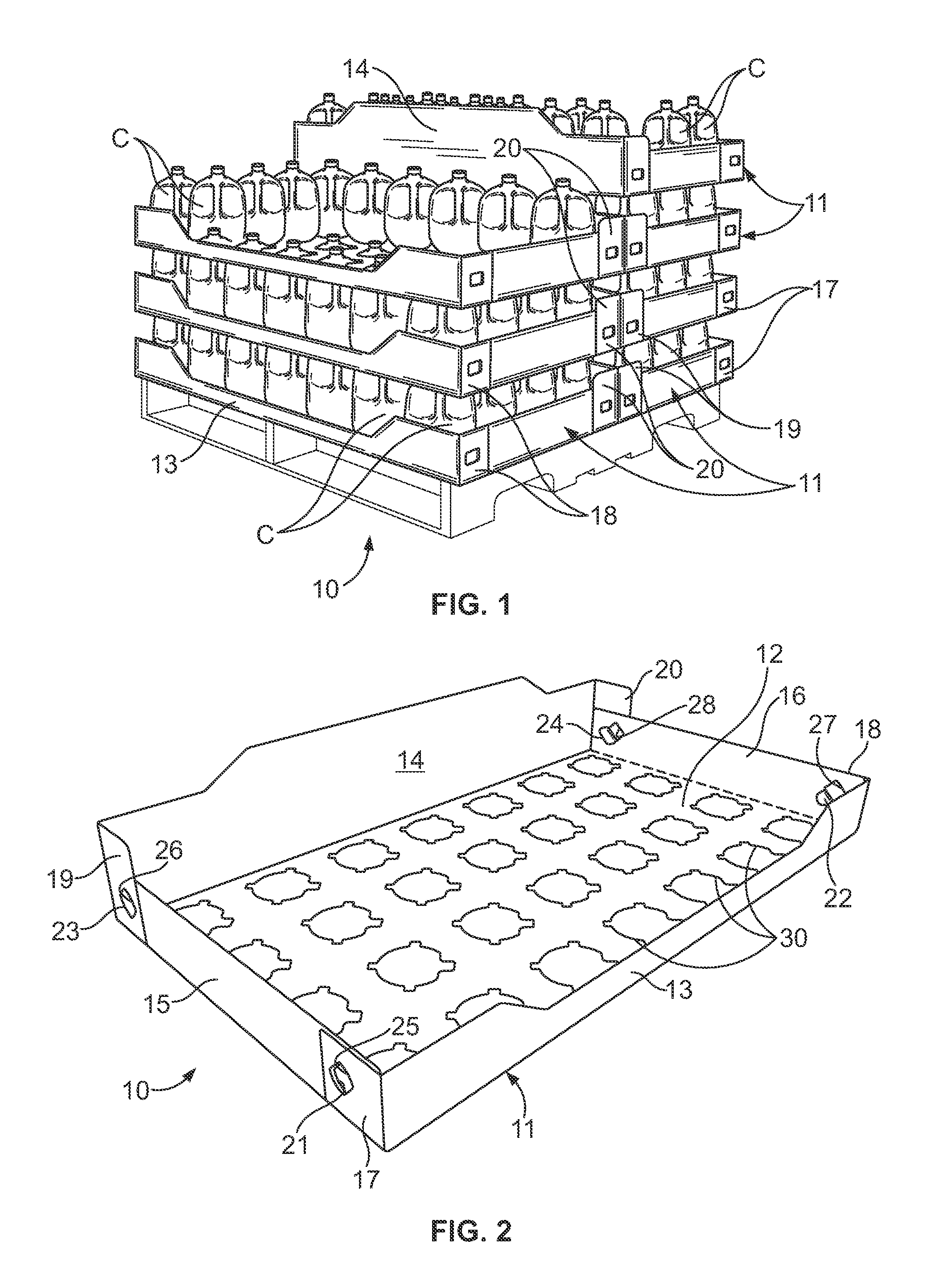

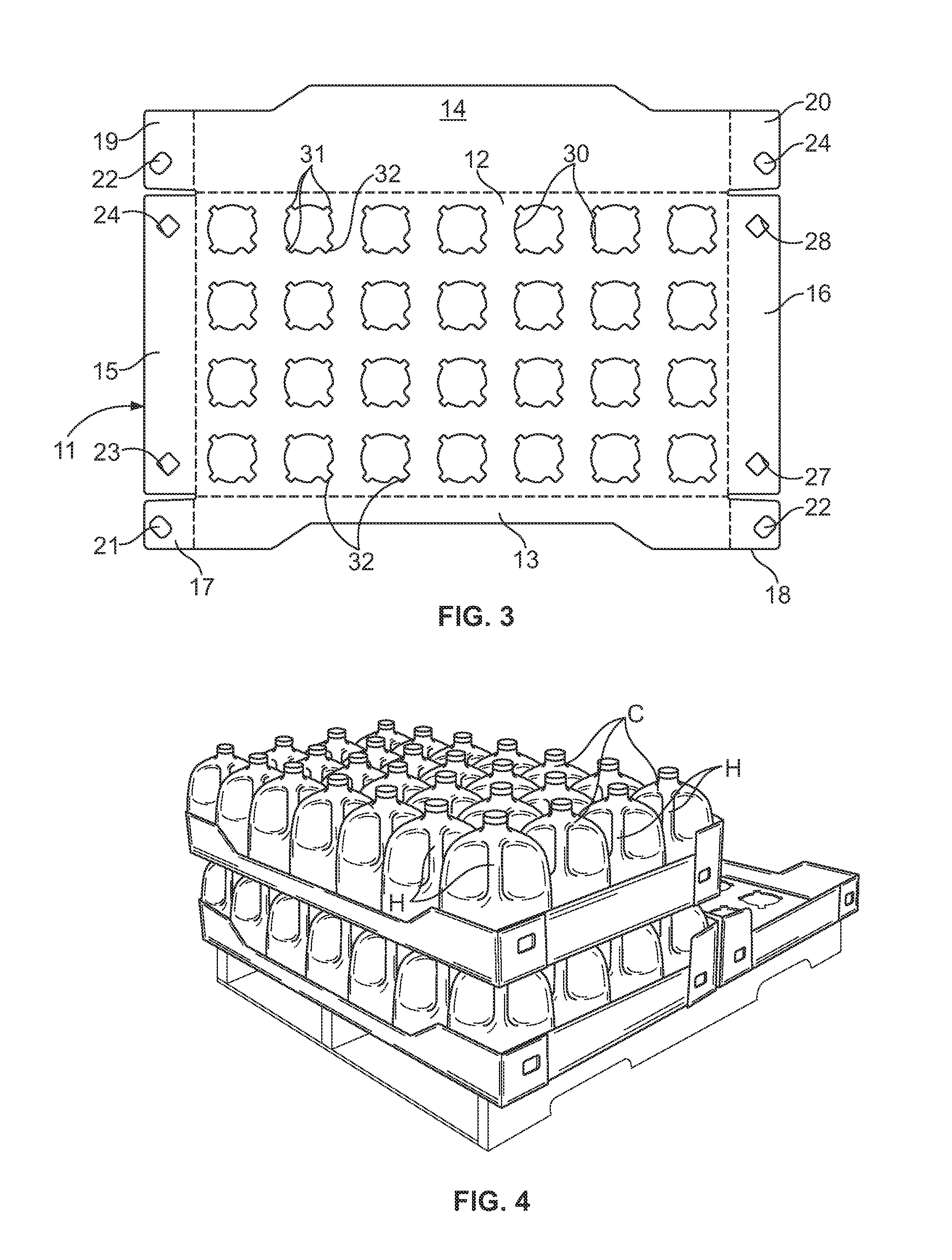

[0029]A first preferred form of the invention is indicated generally at 10 in FIGS. 1-8, wherein a tray 11 has a bottom wall 12, a front wall 13, a back wall 14, and opposite side walls 15 and 16. In the particular embodiment shown, flaps 17 and 18 are on respective opposite ends of the front wall, and flaps 19 and 20 are on respective opposite ends of the back wall. Shaped cuts in each of the flaps form bendable locking tabs 21, 22, 23 and 24 in respective flaps. Openings 25 and 26 are formed through side wall 15 near its opposite ends, and openings 27 and 28 are formed through side wall 16 near its opposite ends. In this arrangement, the side walls 15 and 16 are first folded upwardly, the front and back walls are then folded upwardly and the flaps 17-20 are folded inwardly against the respective adjacent ends of the side walls. The locking tabs 21-24 are then inserted through respective adjacent openings 25-28 and folded downwardly as shown in FIG. 2 to hold the walls in their upw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com