Non-contact optical component surface profile measuring device and method thereof

A technology for optical components and measuring devices, applied in the field of optical measurement, can solve the problems of lack of non-contact surface measuring devices, scratches on the surface of components, stray light affecting the optical system, etc., to achieve the effect of large-scale and high-precision measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will now be described in further detail with reference to the accompanying drawings.

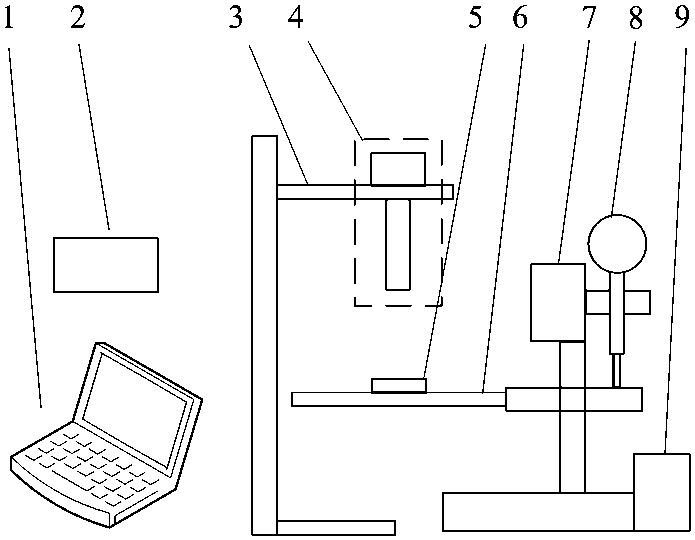

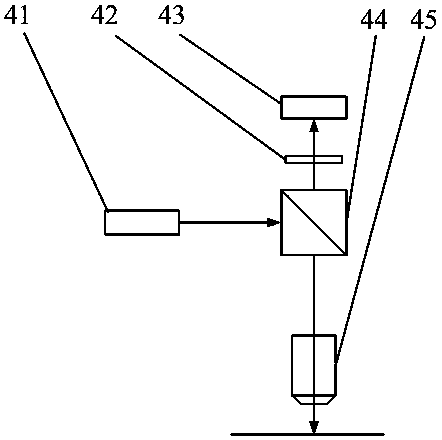

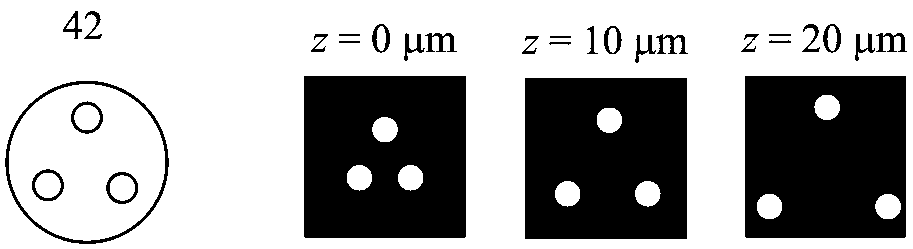

[0029] like figure 1 The non-contact optical element surface profile measurement device shown is used to measure the surface profile of flat surfaces and optical elements with large radius of curvature, including a host computer 1, an electronic control module 2, a probe support structure 3, an optical probe 4, and an element to be measured. 5. Component clamping device 6, Z-axis electric translation stage 7, dial indicator 8 and XY-axis electric translation stage 9 and other components. The optical probe 4 projects a focused light spot on the surface of the element, and the light spot is reflected back to the objective lens 45 to form a three-hole bright spot through the three-hole diaphragm 42 . Since the distance between the bright spots is related to the height position of the light spot, the surface thickness can be obtained by calculating the distance betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com