Method for detecting and controlling laser metal forming height on line

A metal forming and high-level technology, applied in metal material coating process, measuring device, using optical device, etc., to achieve the effect of uniform growth of height and smooth surface of laser forming

Inactive Publication Date: 2010-11-24

XI AN JIAOTONG UNIV +1

View PDF9 Cites 29 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

This patented technique allows for precise placement of small metallic plates on surfaces by controlling how much energy from an external source can be used during formation. By doing this, these techniques allow for more efficient use of materials while maintaining smooth surfaces without causing damage or defects over time.

Problems solved by technology

The technical problem addressed in this patented text relates to improving the formation precision for metallic components during laser melting processes caused by various factors such as temperature fluctuations or material shrinkage over time. These effects may lead to poorly formed part shapes leading to reduced functionality and durability compared to regular production techniques.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

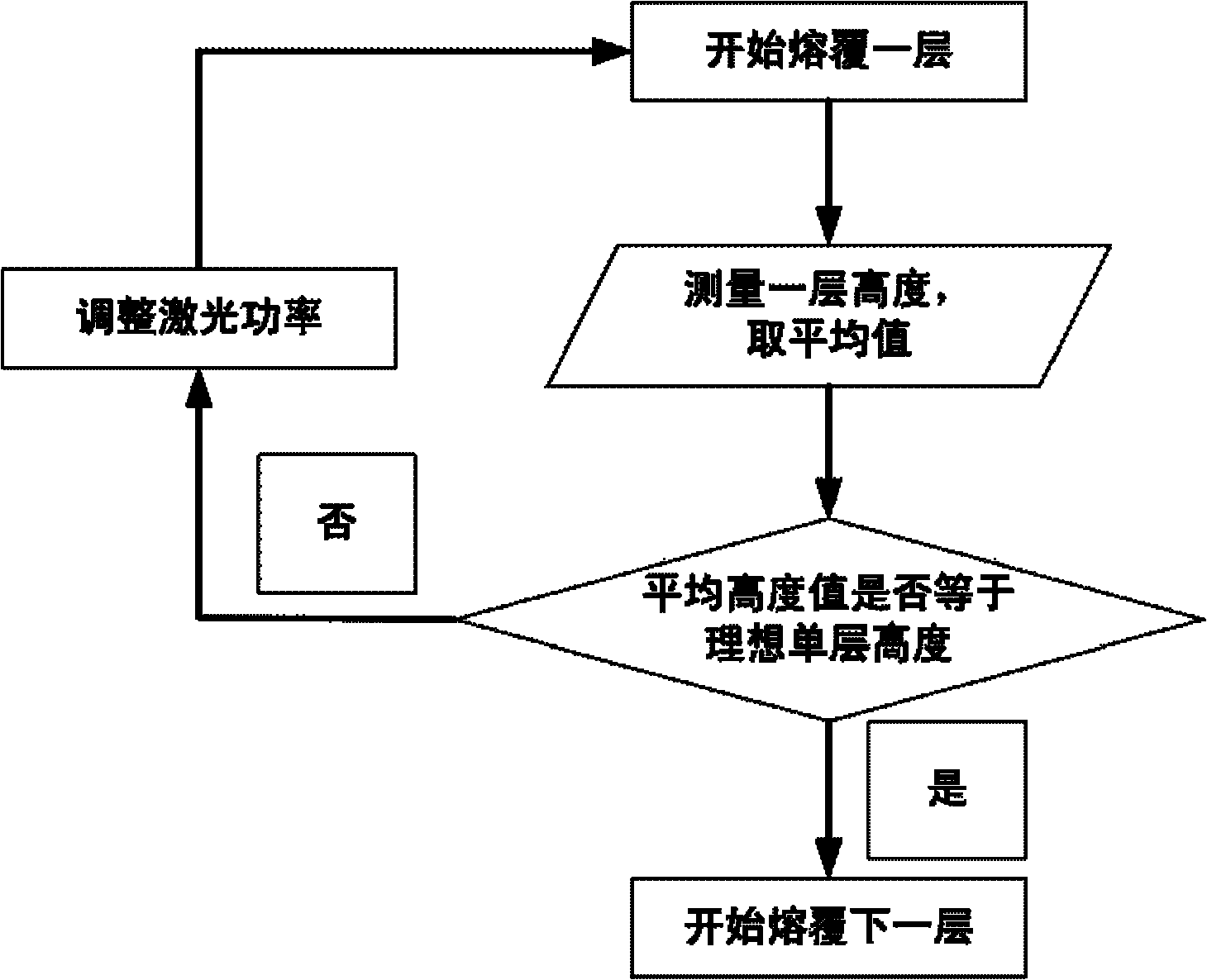

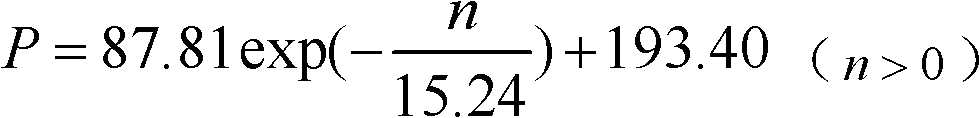

The invention discloses a method for detecting and controlling laser metal forming height on line. The method comprises the following steps of: vertically mounting a laser displacement sensor on a coaxial powder feeding nozzle; ensuring that laser emitted from the sensor is parallel to the laser emitted from a laser device; opening the laser device and performing cladding forming on the substrate by using a computer numerical control system; after a first layer is formed, controlling sensor offset by using the computer numerical control system; moving a detected surface below the sensor; ensuring that the laser emitted from the sensor is reflected by the detected surface and then received and output by a receiver of the sensor; averaging cladding height data by using the computer numerical control system; comparing an average with an ideal single-layer height; if the average is different from the ideal single-layer height, making the increased height of a cladding consistent with the ideal single-layer height by adjusting the power of the laser device; and continuing performing next cladding and height detection until a component is formed to a needed height by cladding, wherein the laser power is adjusted to gradually reduce along with the change of accumulation layers so as to ensure the uniform growth of the height of each layer.

Description

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Owner XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com