Genetic algorithm-based automatic stereoscopic warehouse goods allocation optimization method

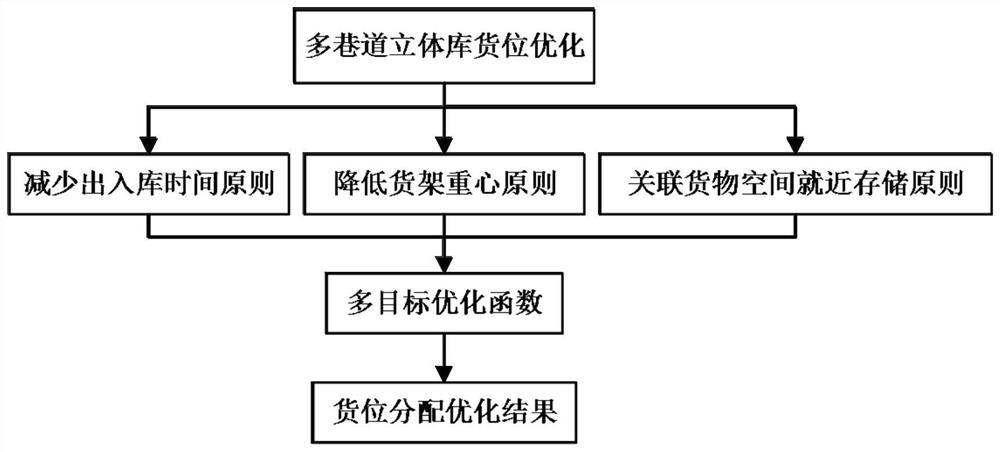

A three-dimensional warehouse and space allocation technology, applied in genetic rules, constraint-based CAD, design optimization/simulation, etc., can solve the problems of low spatial aggregation of related products, low handling efficiency, poor shelf stability, etc., and achieve wide application The effect of reducing the handling time and lowering the center of gravity of the shelf

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

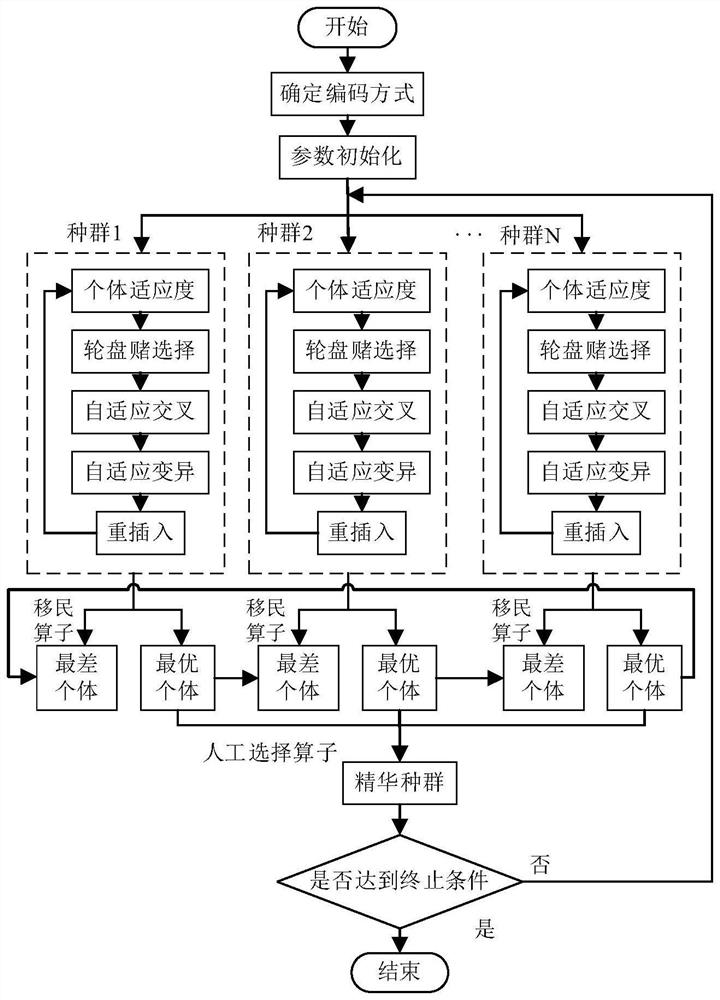

Method used

Image

Examples

Embodiment

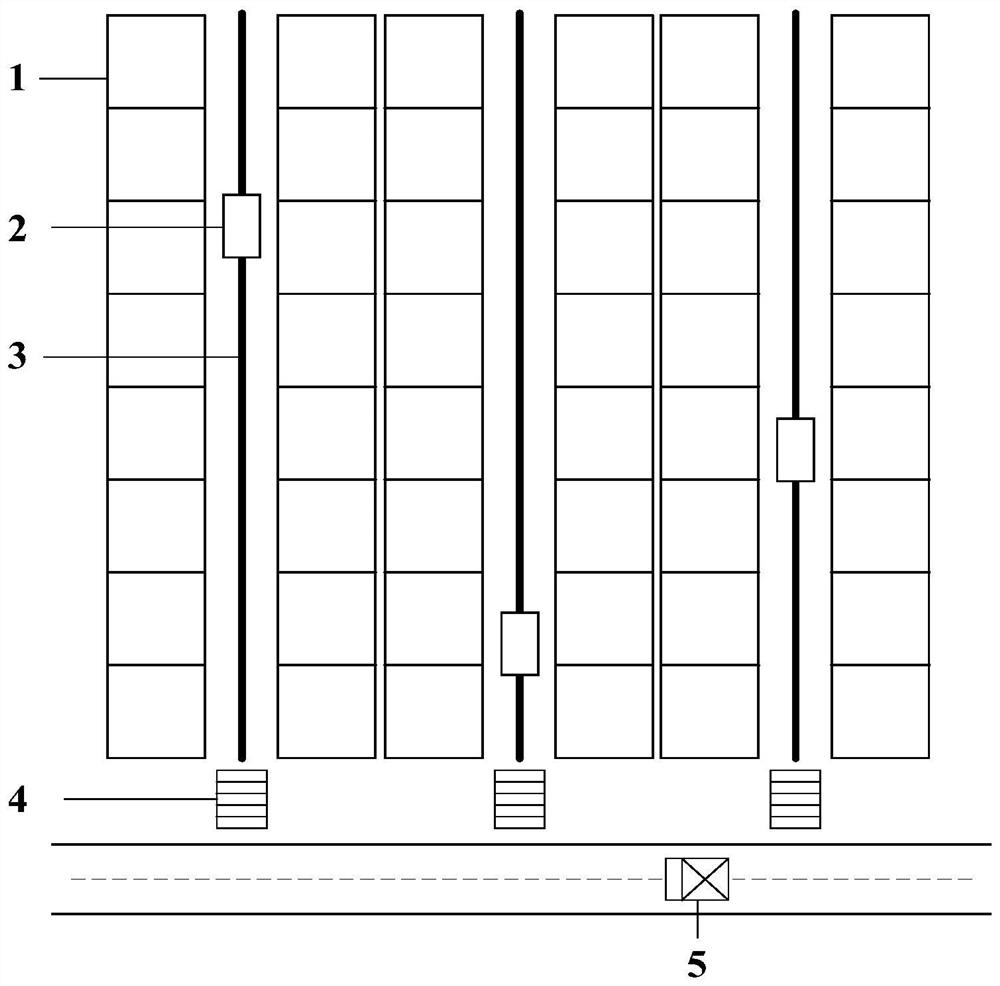

[0129] Taking the automatic three-dimensional warehouse of a certain auto parts manufacturing enterprise as an example below, the practical application of the present invention will be further explained.

[0130] First, analyze and process the historical order information of the automated three-dimensional warehouse to obtain the basic component information for cargo location optimization:

[0131] The basic data of the shelves in the automated three-dimensional warehouse of auto parts enterprises are shown in Table 1.

[0132] Table 1 Basic Data of Auto Parts Enterprise Automated Stereoscopic Warehouse Shelves

[0133]

[0134] Attributes such as type, quality, storage frequency and initial coordinates of parts are shown in Table 2.

[0135] Table 2 Basic data of components

[0136]

[0137] In order to analyze the optimization effect of the objective function, each objective function is simulated through the improved genetic algorithm to verify the effectiveness of e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com