Combined production line for furniture wood processing

A production line and wood technology, which is applied in the direction of wood processing equipment, metal processing equipment, and the joining of wooden veneers, can solve the problems of polluting the production environment of the workshop, restricting the scale and standardization of furniture products, and reducing the cost of furniture manufacturing. Achieve the effect of improving the level of large-scale production, enhancing market competitiveness, and reducing handling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

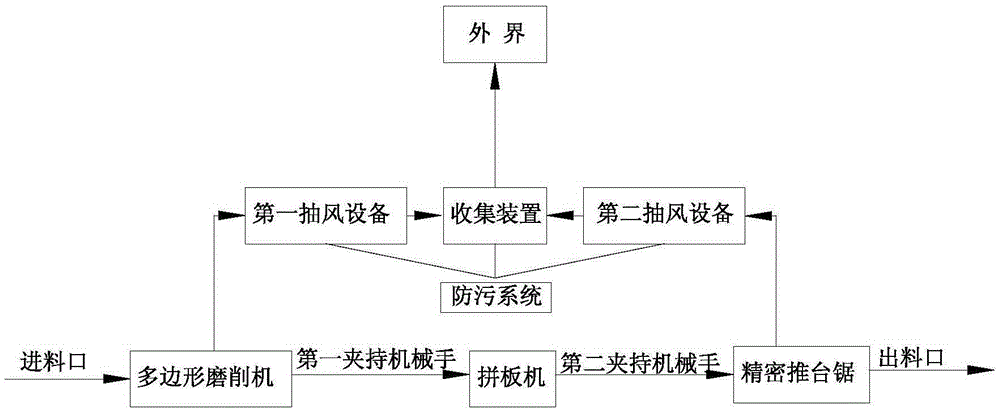

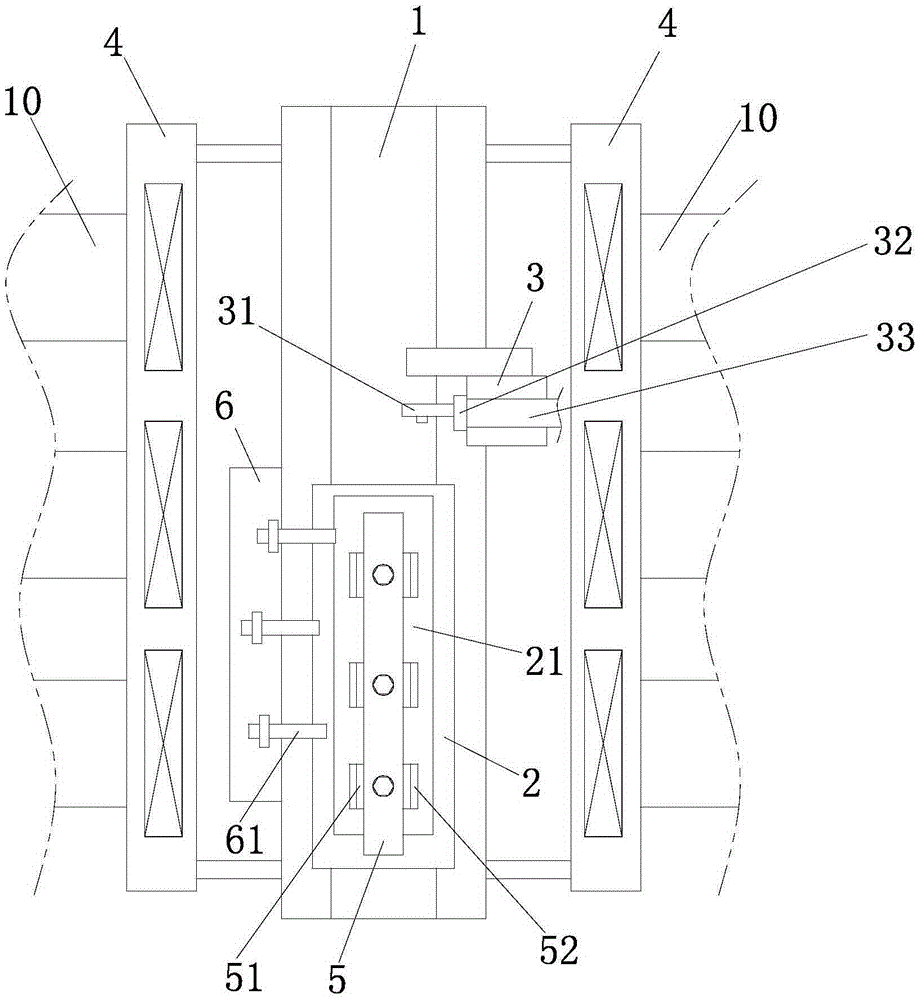

[0022] refer to Figure 1 to Figure 4 , a combined furniture wood processing production line, comprising a polygonal grinder for grinding wood into polygonal wood strips, the polygonal grinder is provided with a feed port.

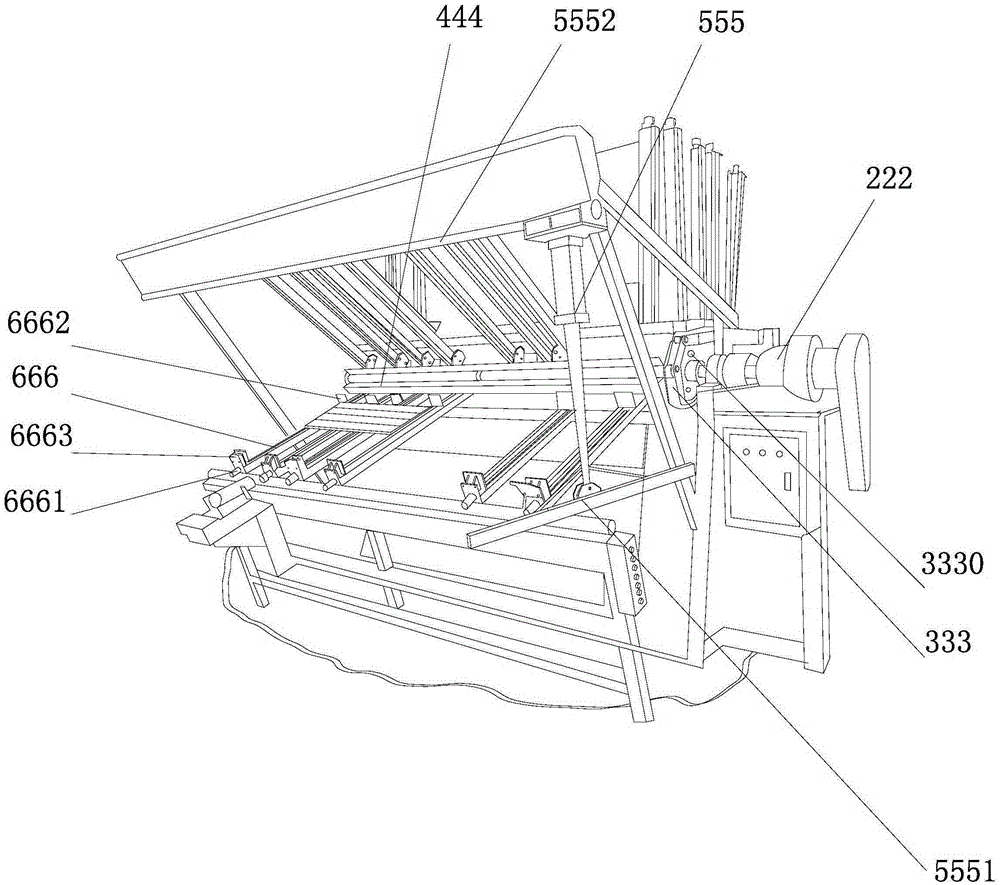

[0023] The jigsaw machine is used to assemble several wooden strips into planks.

[0024] The first clamping manipulator is arranged between the jigsaw machine and the polygonal grinding machine, and is used for clamping and sending the wooden strips formed by the polygonal grinding machine to the jigsaw machine.

[0025] The precision sliding table saw is used for cutting the wooden board into a specified size, and the precision sliding table is also provided with a discharge port.

[0026] The second clamping manipulator is arranged between the jigsaw and the precision table saw, and is used to clamp and send the planks formed by the jigsaw to the precision table saw.

[0027] The anti-fouling system includes the first ventilation device for sucking th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com