High-frequency compacted wood combined production line

A high-frequency, production-line technology, used in wood compression, wood processing, wood processing appliances, etc., can solve problems such as inability to solve springback, not including detection, processing, splicing, insufficient automation, etc., to improve the level of large-scale production, reduce The effect of handling time and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

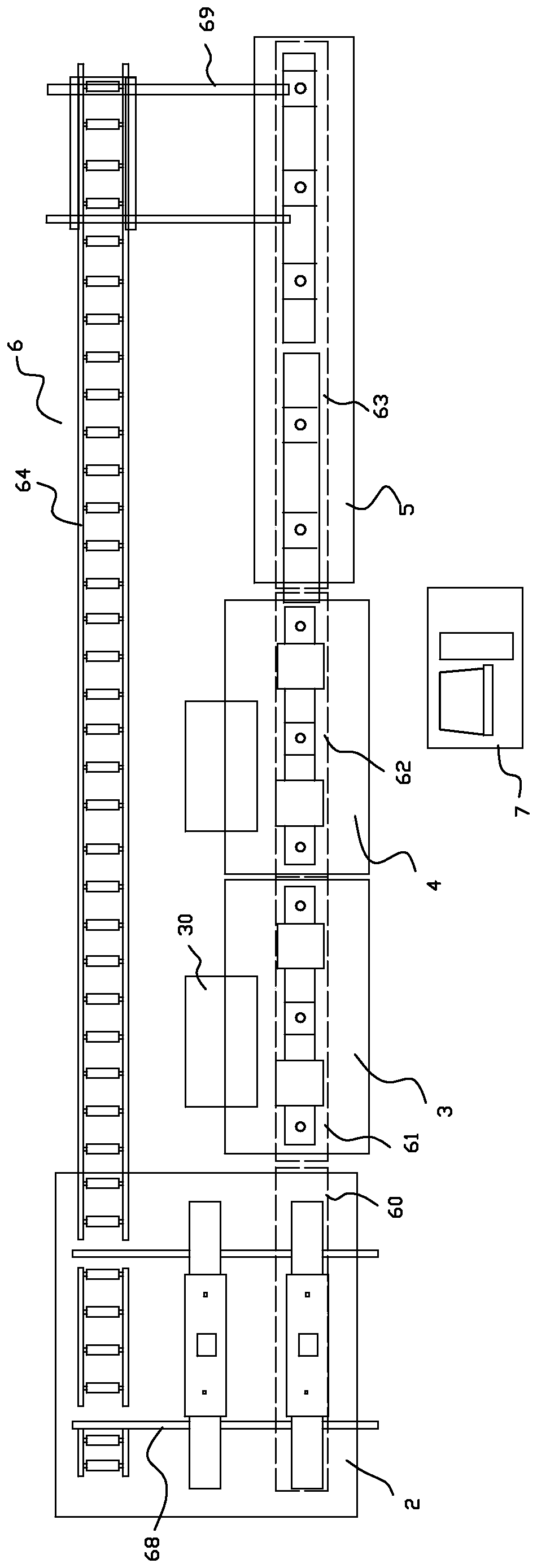

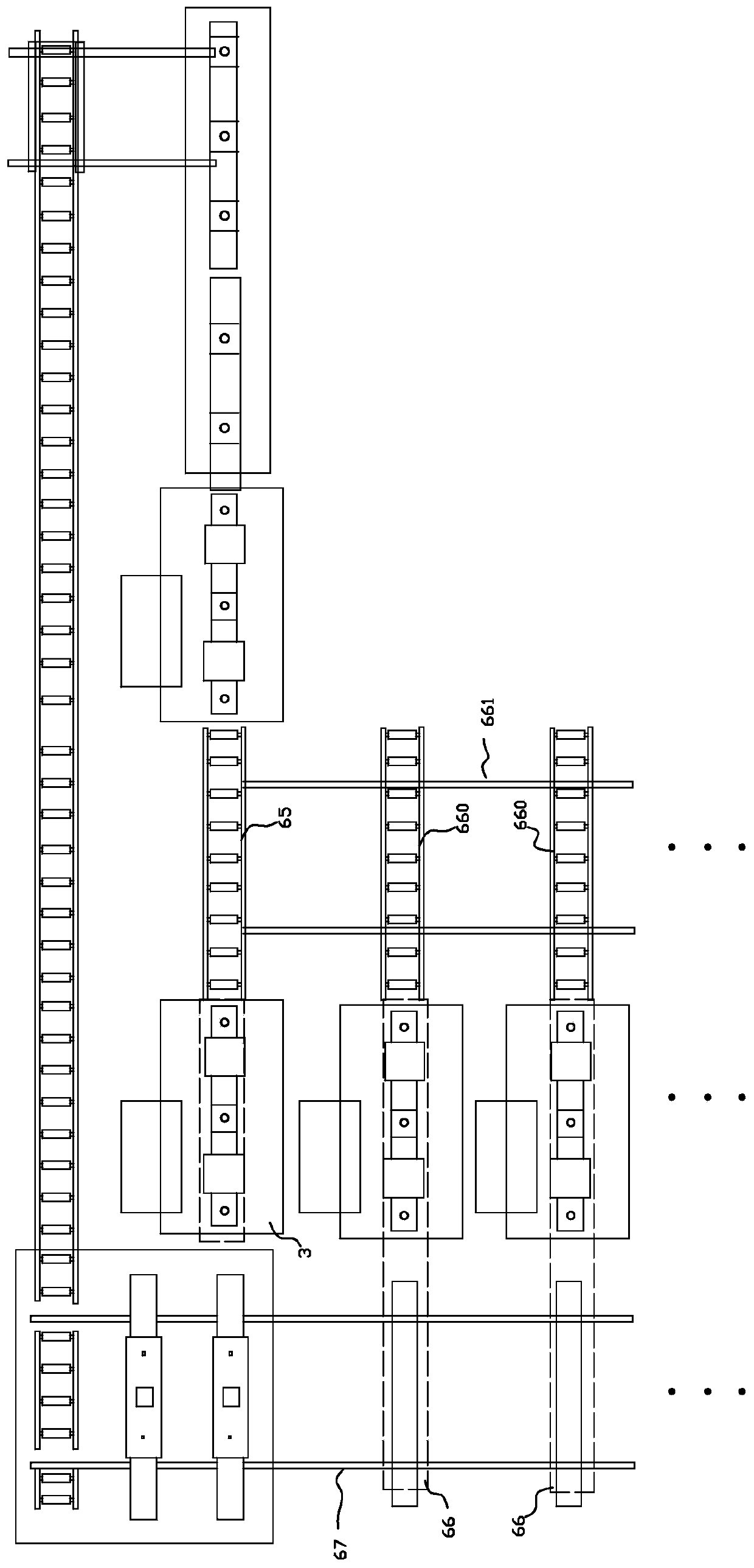

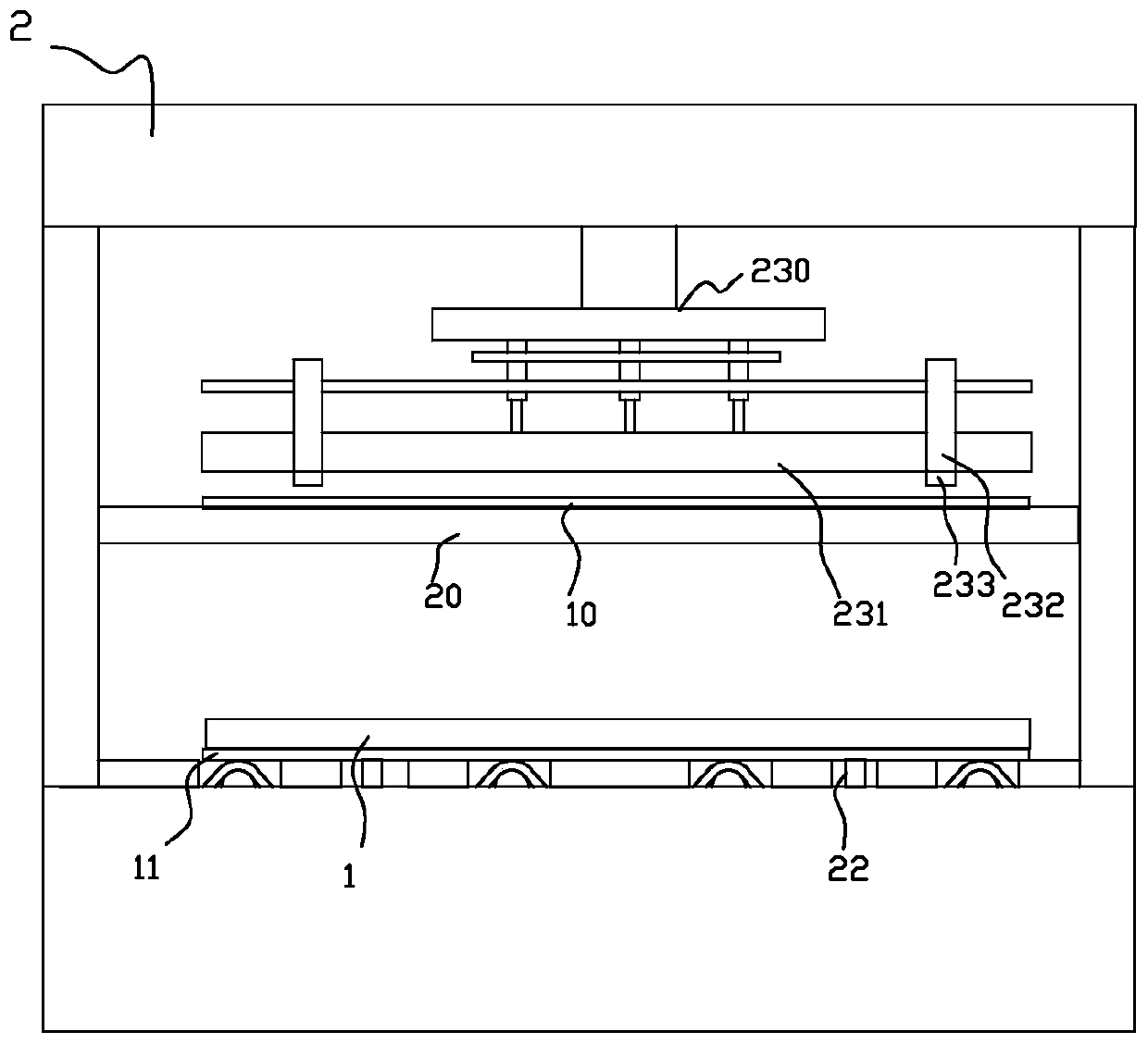

[0041] The present invention is a kind of high-frequency compacted wood combination production line, such as figure 1 As shown, the production line includes operating equipment and auxiliary plates, and the auxiliary plates include an upper steel plate 10 and a lower steel plate 11 for clamping wood 1; the operating equipment includes

[0042] The input and take-out part 2 is configured to put the upper steel plate 10 and the lower steel plate 11 into the transmission chain station, and take out the upper steel plate 10 and the lower steel plate 11 after the wood 1 is processed; wherein the upper steel plate 10, The lower steel plate 1 clamps the wood 1 to form a processing assembly;

[0043] The auxiliary high-frequency softening part 3 is equipped with a high-frequency heating device to heat and soften the processing components;

[0044] The main high-frequency stamping part 4 is equipped with a high-frequency heating device and a press to continue heating and compressing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com