Automatic aluminum-plastic section milling process and automatic aluminum-plastic section milling equipment

An automatic milling and profile technology, which is applied in the direction of milling machine equipment, milling machine equipment details, metal processing equipment, etc., can solve the problems of low degree of automation, labor and material resources consumption, etc., to facilitate workshop management, reduce handling time, and save manpower and material resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

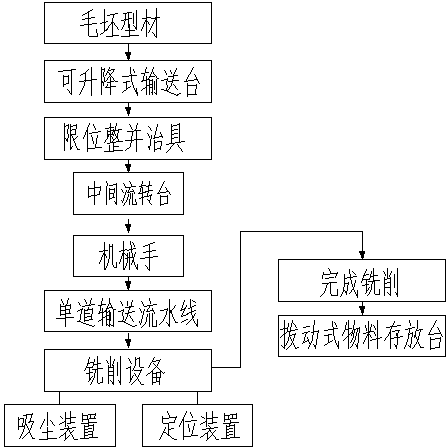

[0033] Such as figure 1 The automatic milling process of aluminum-plastic profiles shown is realized through the following process steps: blank profiles, liftable conveyor table, alignment and limit fixture, intermediate flow table, manipulator, single-channel conveyor line, milling equipment, and complete milling.

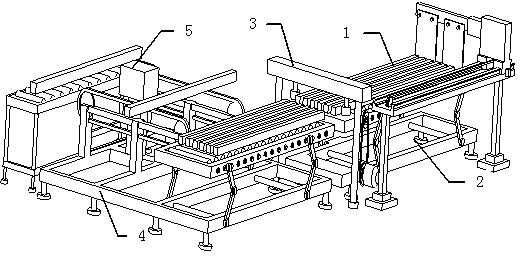

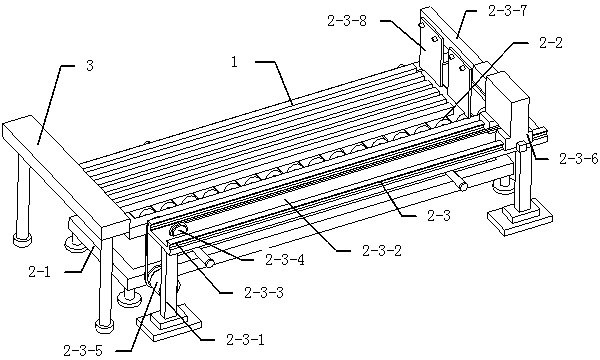

[0034] Such as Figures 2 to 9 In the automatic milling equipment for aluminum-plastic profiles shown, the entire row of aluminum-plastic blank profiles is fed on the liftable conveying table, and the entire row of aluminum-plastic blank profiles is combined and transported to the middle flow table through the limit alignment jig. There is a clamping manipulator on the edge of the middle flow table, and one end of the single-channel assembly line is installed at the feeding port of the milling equipment. The milling equipment is equipped with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com