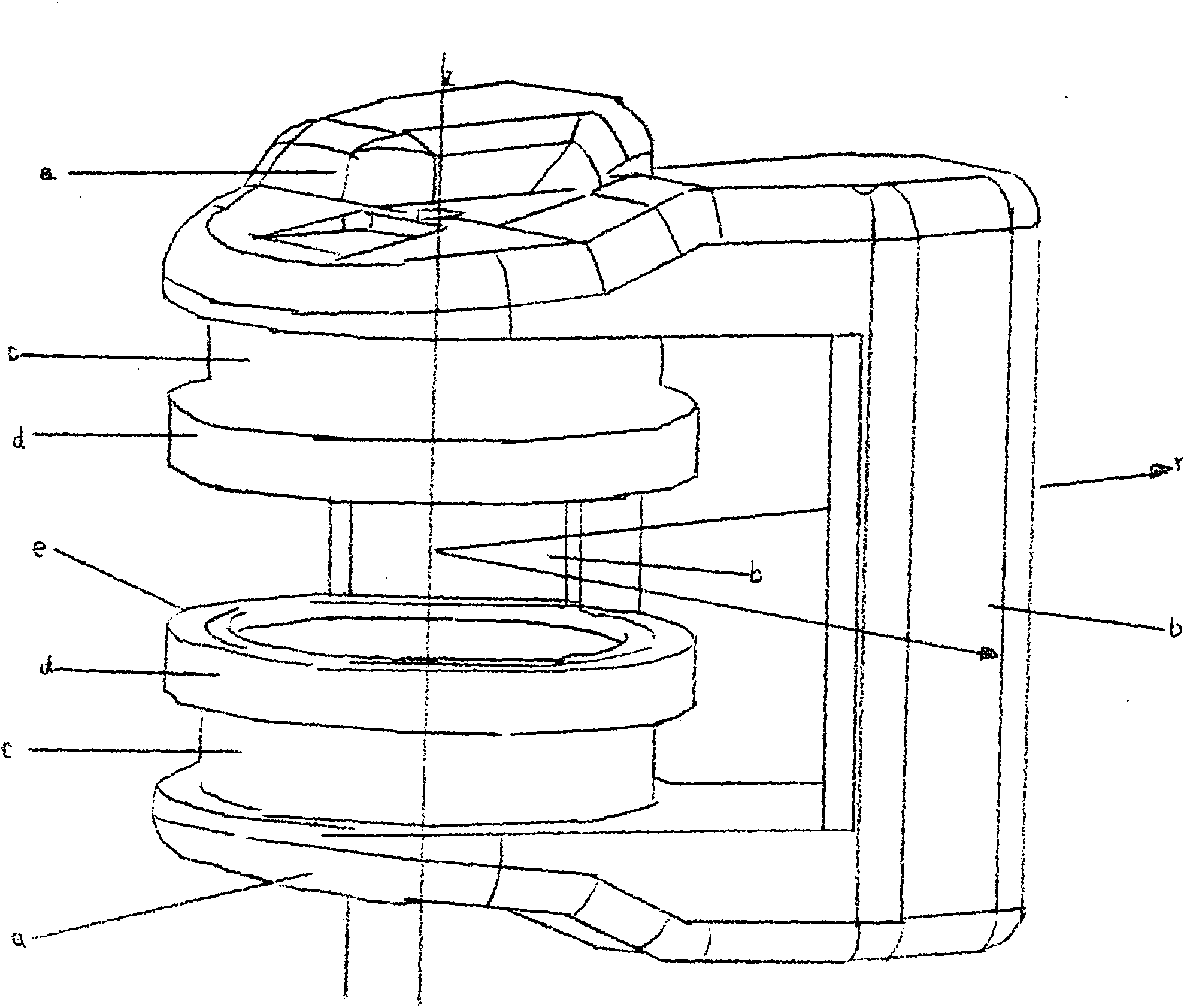

High-field-intensity focusing nuclear magnetic resonance magnetic field and preparation method thereof

A nuclear magnetic resonance and strong focusing technology, which is applied in the directions of magnetic resonance measurement, magnetic variable measurement, and measuring devices, can solve the problems of low magnetic field intensity, poor uniformity and stability of the magnetic field, and the specific structure is not explained, and achieve a uniform magnetic field. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

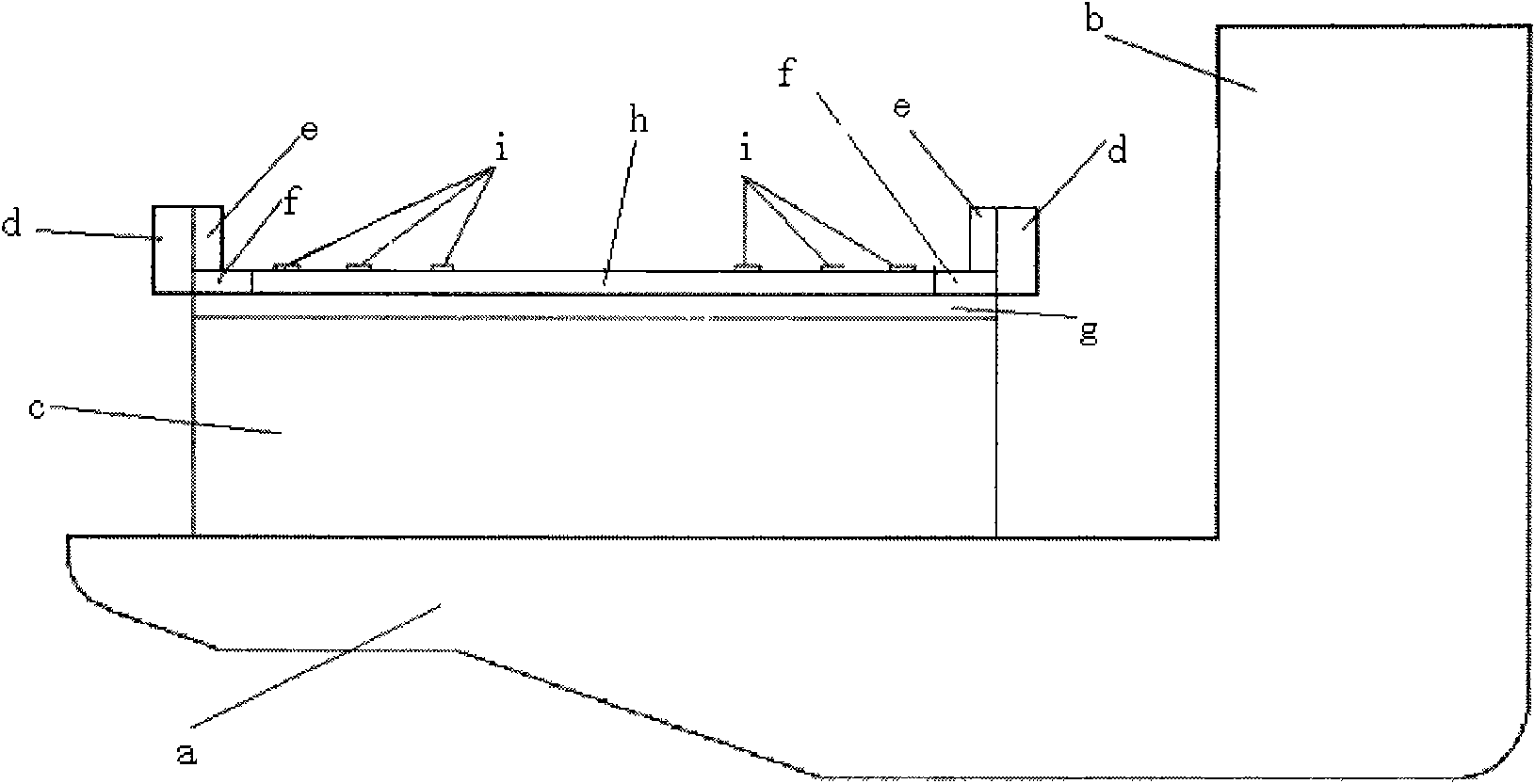

[0037] Magnetic field strength in working area: B 0 =0.5T

[0038] Main magnetic block and magnetic ring magnet material: N45 sintered neodymium iron boron magnet

[0039] The performance requirements of the main magnetic block and the concentrating ring magnet: Remanence Br 13.2~13.5KGs

[0040] Magnetic induction coercivity Hcb 11.5~12.5KOe

[0041] Intrinsic coercivity Hcj 12.5~13.5KOe

[0042] Maximum magnetic energy product (BH) max 43~45MGO

[0043] Working air gap: height 490mm

[0044] Width 1100mm

[0045] Magnetic pole size: vertical width 1100mm

[0046] Horizontal length 1100mm

[0047] Main magnet height 270mm

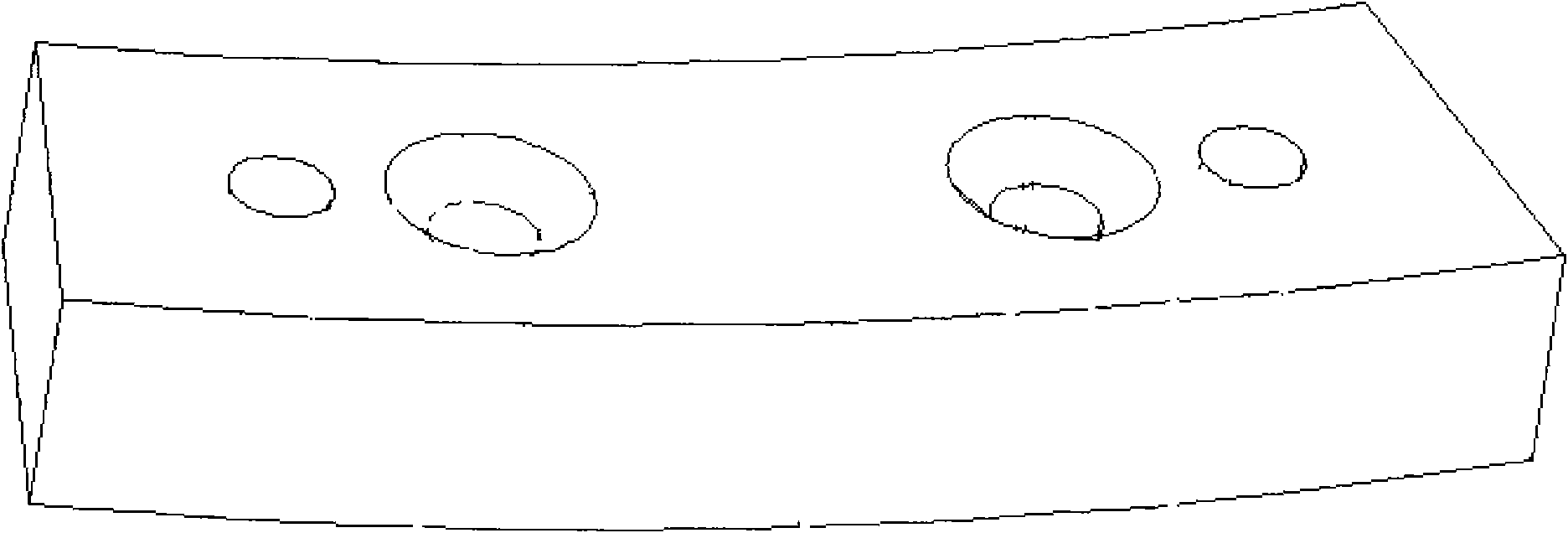

[0048] Concentrator ring unit magnet size: angle 6°

[0049] Wall thickness 40mm

[0050] Vertical height 40mm

[0051] Uniformity of magnetic field: 8ppm in Φ300mm sphere, 3ppm in Φ200 sphere

[0052] Magnetic field sta...

example 2

[0055] Magnetic field strength in working area: B 0 =0.55T

[0056] Main magnet block and magnetic ring magnet material: N45 sintered neodymium iron boron magnet

[0057] The performance requirements of the main magnetic block and the concentrating ring magnet: Remanence Br 13.2~13.5KGs

[0058] Magnetic induction coercivity Hcb 11.5~12.5KOe

[0059] Intrinsic coercivity Hcj 12.5~13.5KOe

[0060] Maximum magnetic energy product (BH) max 43~45MGO

[0061] Working air gap: height 490mm

[0062] Width 1100mm

[0063] Magnetic pole size: vertical width 1100mm

[0064] Horizontal width 1100mm

[0065] Main magnet height 300mm

[0066] Concentrator ring unit magnet size: angle 6°

[0067] Wall thickness 40mm

[0068] Vertical height 40mm

[0069] Uniformity of magnetic field: 8ppm in Φ300mm sphere, 3ppm in Φ200 sphere

[0070] Magnetic field stability: The temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com