Small-sized dipolar single-phase generator

A single-phase generator, two-pole technology, applied in synchronous generators, asynchronous induction motors, electrical components, etc., can solve the problems of poor output voltage waveform, limited use range, high waveform sinusoidal distortion rate, and achieve stable output voltage, Wide range of applications and highly adaptable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

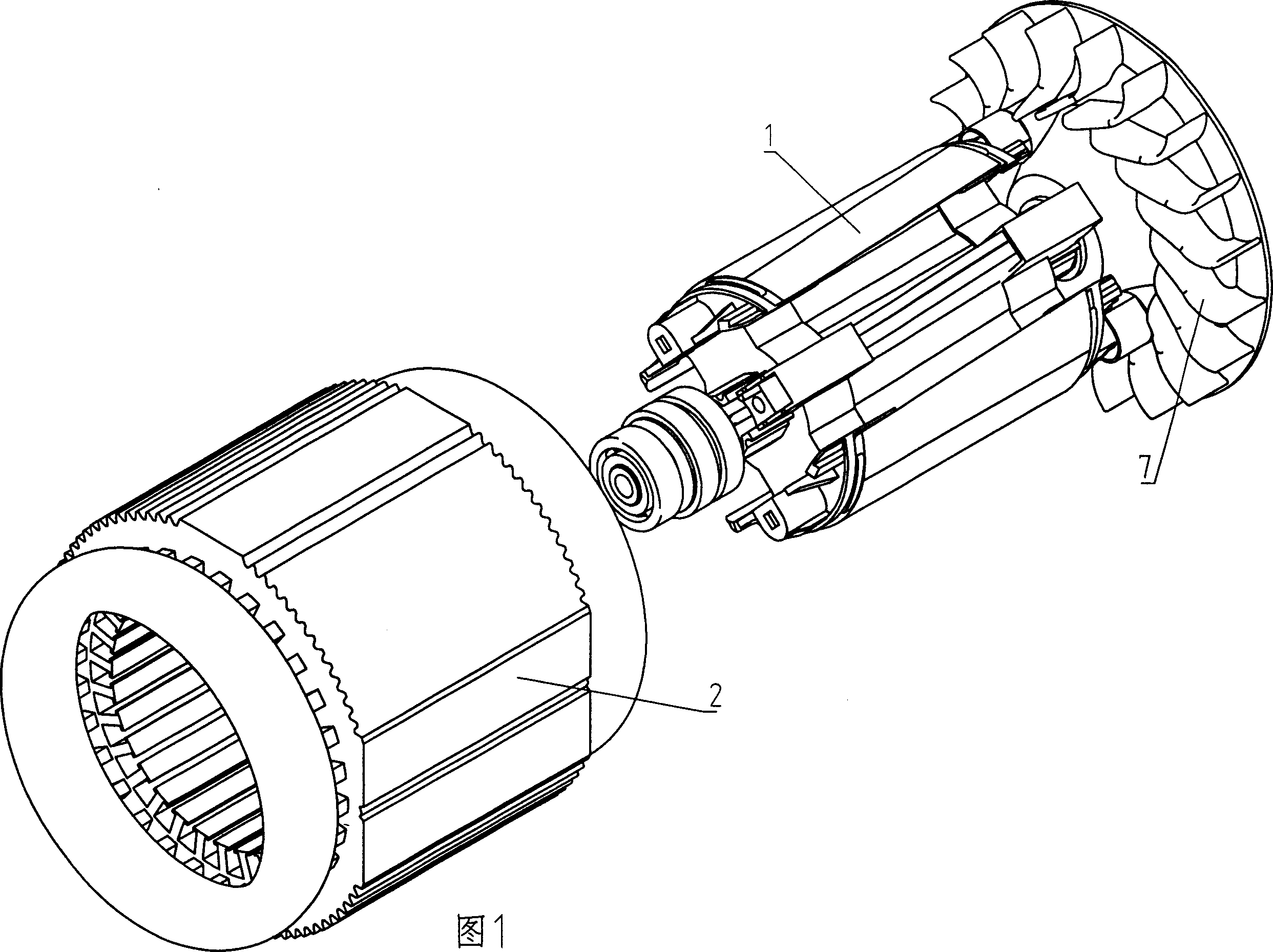

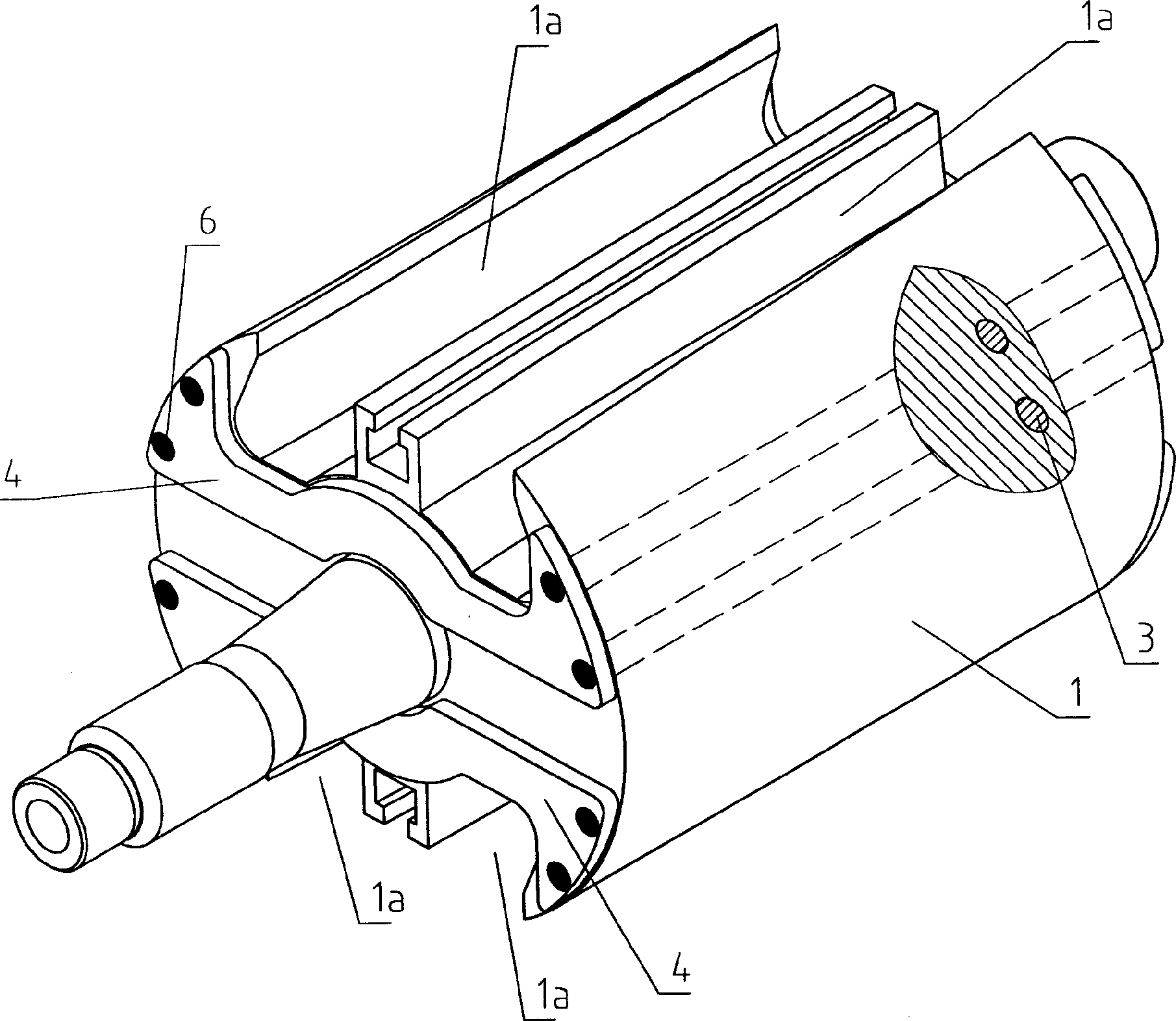

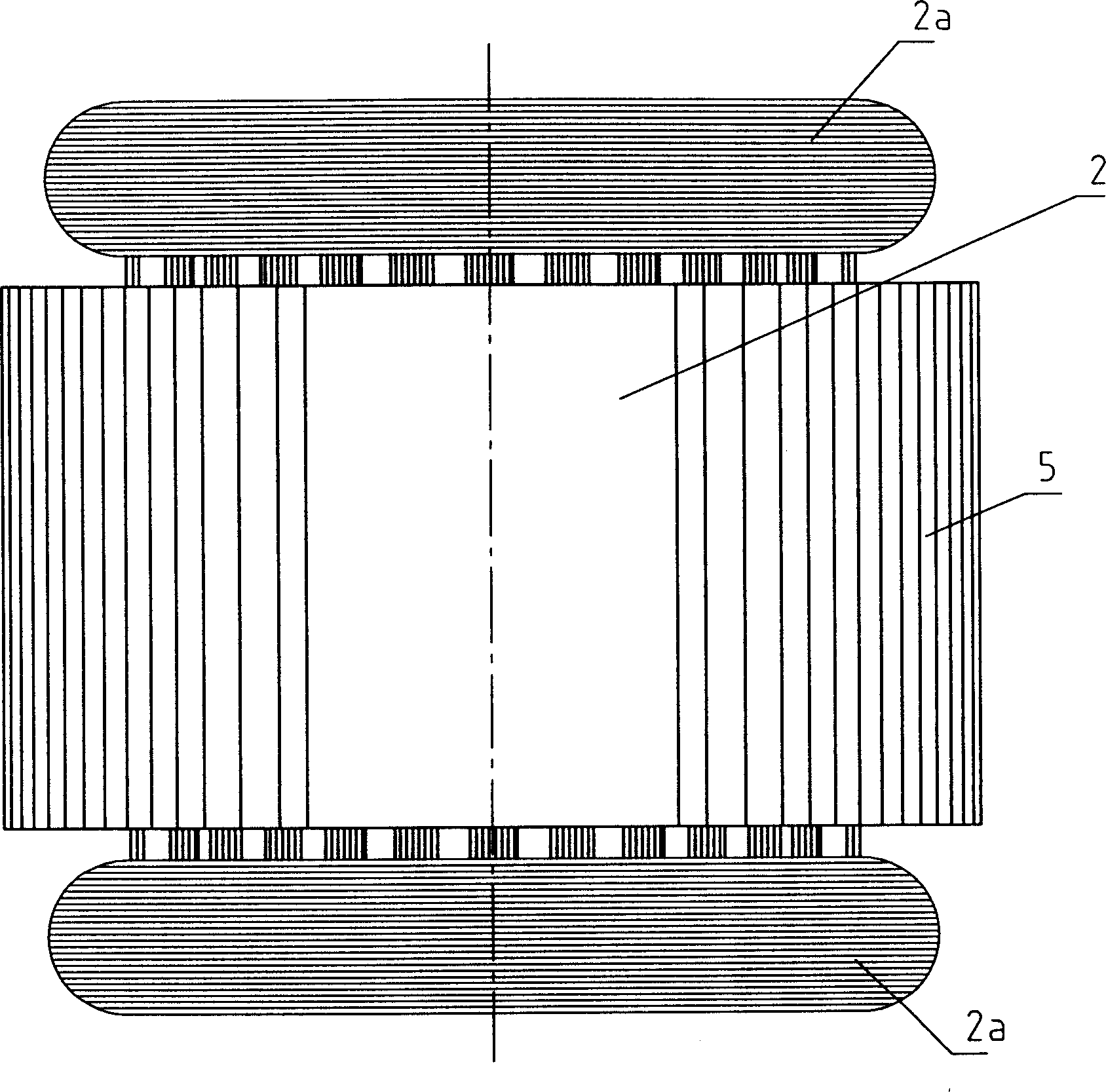

[0018] As shown in Figures 1 to 5, a 12KW small two-pole single-phase generator is composed of a rotor 1 and a spindle 2. The iron core of the rotor 1 is provided with two sets of damping windings, and each set of damping windings consists of damping strips 3 and The damping plate 4 is composed of the damping plate 4, which is arranged on both ends of the iron core. After the damping bar 3 axially passes through the iron core, the two ends are reliably welded (spot welded) to the damping plate 4; the winding coil 2a on the spindle 2 is Equidistant two-pole winding structure.

[0019] figure 2 There are four damping strips 3 in each set of damping windings on the core of the middle rotor 1, the cross section of the damping strips 3 is circular and the diameter is between 2-8mm, and the thickness of the damping plate 4 is 1-8mm. The damping strip 3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com