Electromagnetic wave welding method and device for solar cells

A technology for solar cells and welding devices, applied in high-frequency current welding equipment, welding equipment, circuits, etc., can solve the problems of high energy consumption, broken cells, and low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

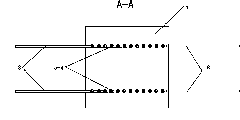

[0025] Such as figure 1 , 3 , 4, 5, and 6, an electromagnetic wave welding method for solar cells, comprising the following steps: superimposing solar cells 7 and welding ribbons 8 on a non-magnetic workbench 1, so that the welding ribbons 8 and solar cells The main grid line of the sheet 7 is in contact with each other, and the elastic pressing device 5 is used to press the welding ribbon 8 and the battery sheet 7, and the high-frequency power supply 2 is used to supply power to the two copper tube induction coils 3 arranged under the surface of the workbench 1. The tube induction coil 3 is in a "U" shape, and the copper tube induction coil 3 is cooled by the cooling medium 4 flowing inside, and the high-frequency oscillating electromagnetic waves generated by the copper tube induction coil 3 make the main grid lines of the welding strip 8 and the battery sheet 7 Both generate eddy current and generate heat, so that the welding ribbon 8 and the main grid line of the battery ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Frequency range | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com