Magnetron sputtering device

A magnetron sputtering and sputtering technology, applied in the field of sputtering, can solve problems such as low utilization rate of target materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

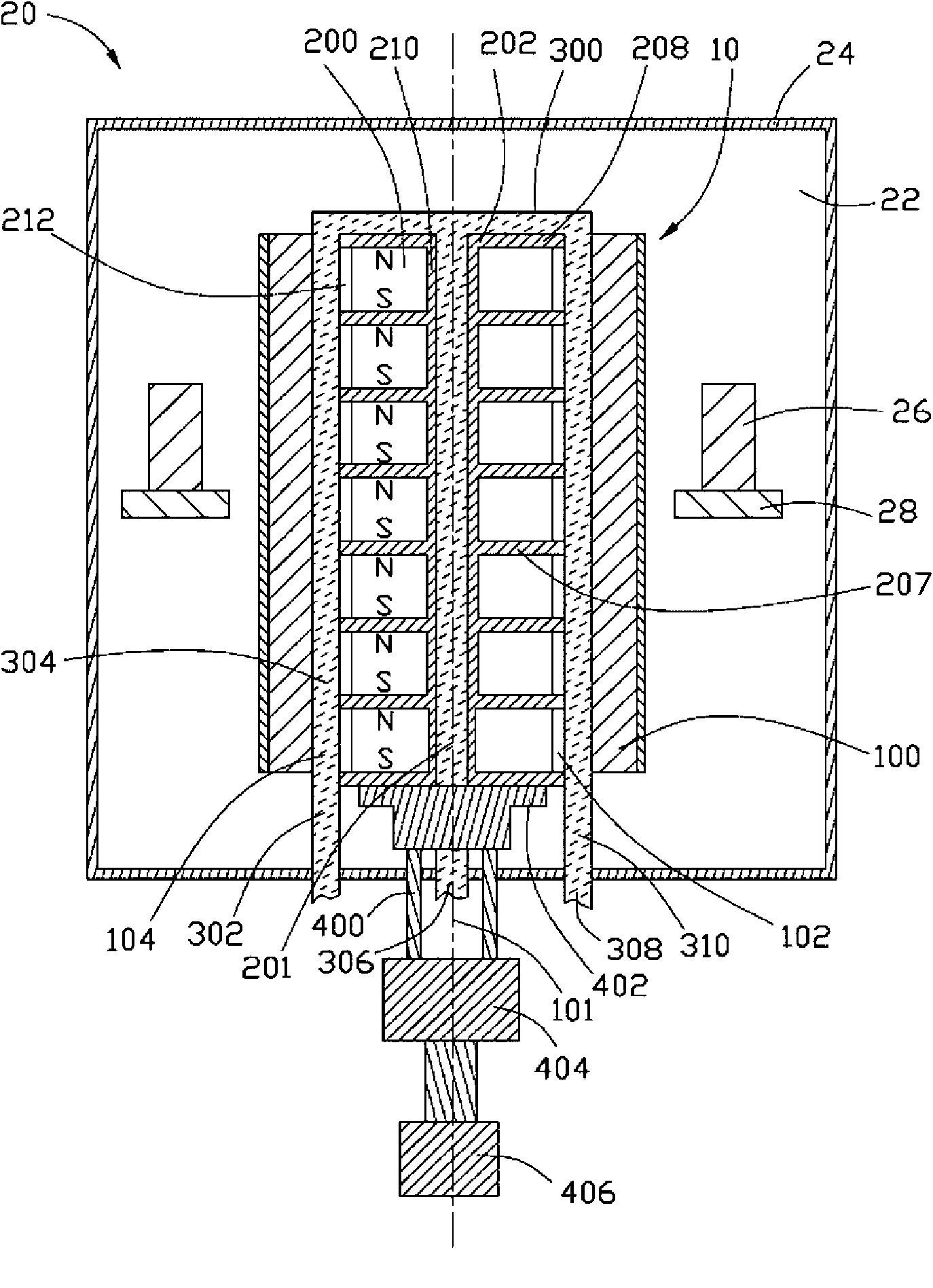

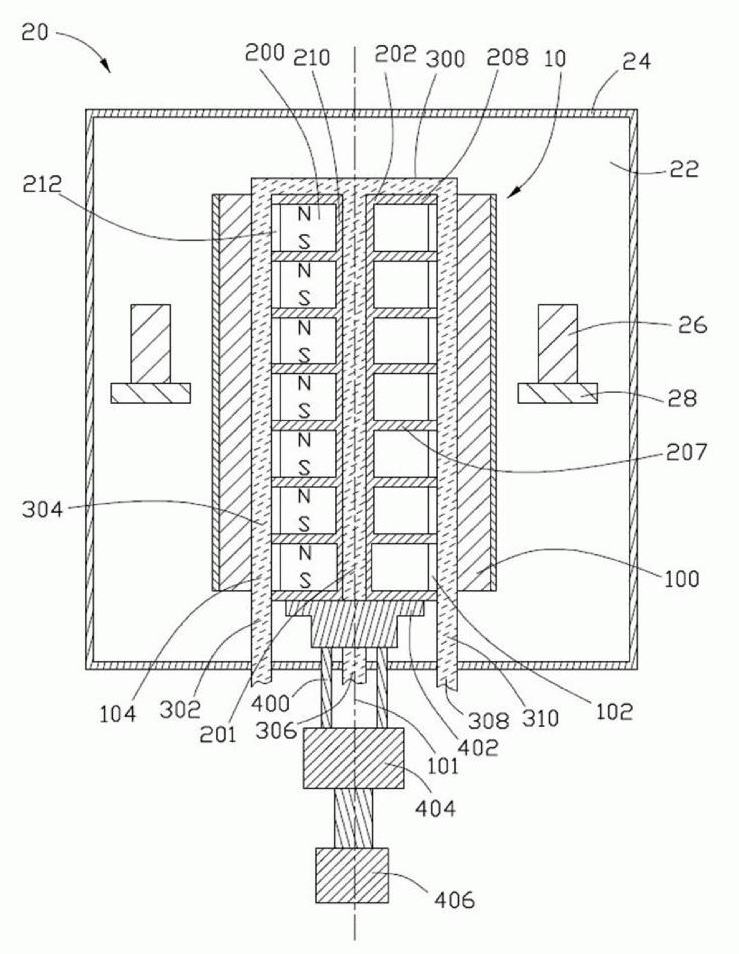

[0007] Please combine figure 1 , The magnetron sputtering device 20 of the preferred embodiment of the present invention includes a housing 24 , a target source 10 and a plurality of bases 28 . The housing 24 defines a cylindrical sputtering space 22 . The target source 10 and a plurality of seats 28 are located in the sputtering space 22 . The workpiece 26 to be sputtered can be placed on the base 28 to be sputtered in the sputtering space 22 .

[0008] The target source 10 includes a target 100 , a magnetic unit 207 , a cooling unit 300 and an actuator 400 . The target 100 is cylindrical and has a central axis 101 . The target 100 defines a cylindrical cavity 102 .

[0009] The magnetic unit 207 is disposed in the cylindrical cavity 102 defined by the target 100 along the central axis 101 . The magnetic unit 207 includes a bracket 202 and a plurality of magnetic elements 200 fixed on the bracket 202 . The bracket 202 includes a cylindrical tube 210 and a plurality of p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com