Spring operating mechanism cooperated with 126kV vacuum circuit breaker separation-integration characteristic

A vacuum circuit breaker and operating mechanism technology, applied in the direction of high-voltage air circuit breakers, circuits, electrical components, etc., can solve the problems of high machining accuracy of parts and complex structure of spring operating mechanism, etc., to achieve superior performance, reliability, It is beneficial to extinguish and reduce the effect of opening and closing work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

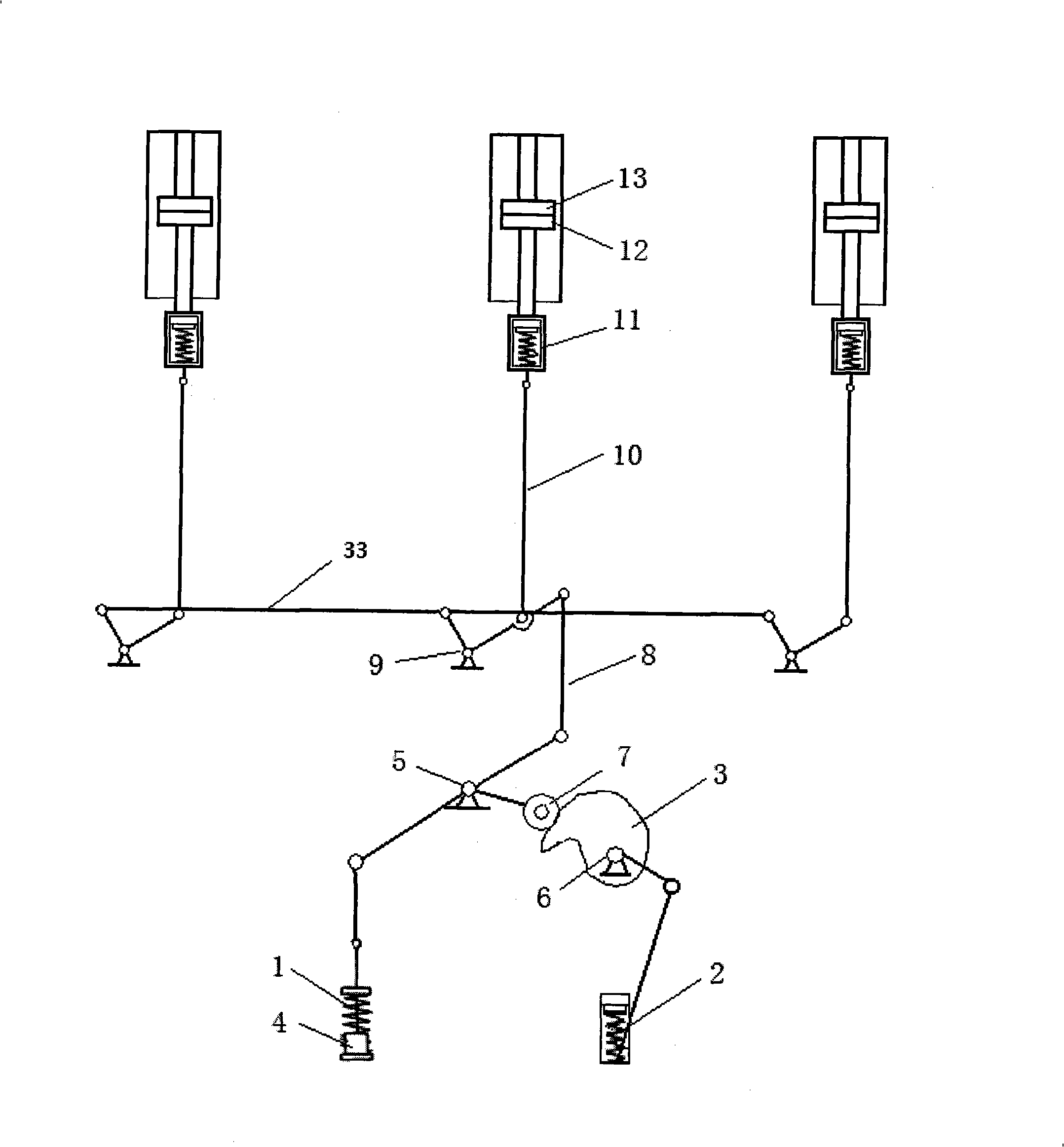

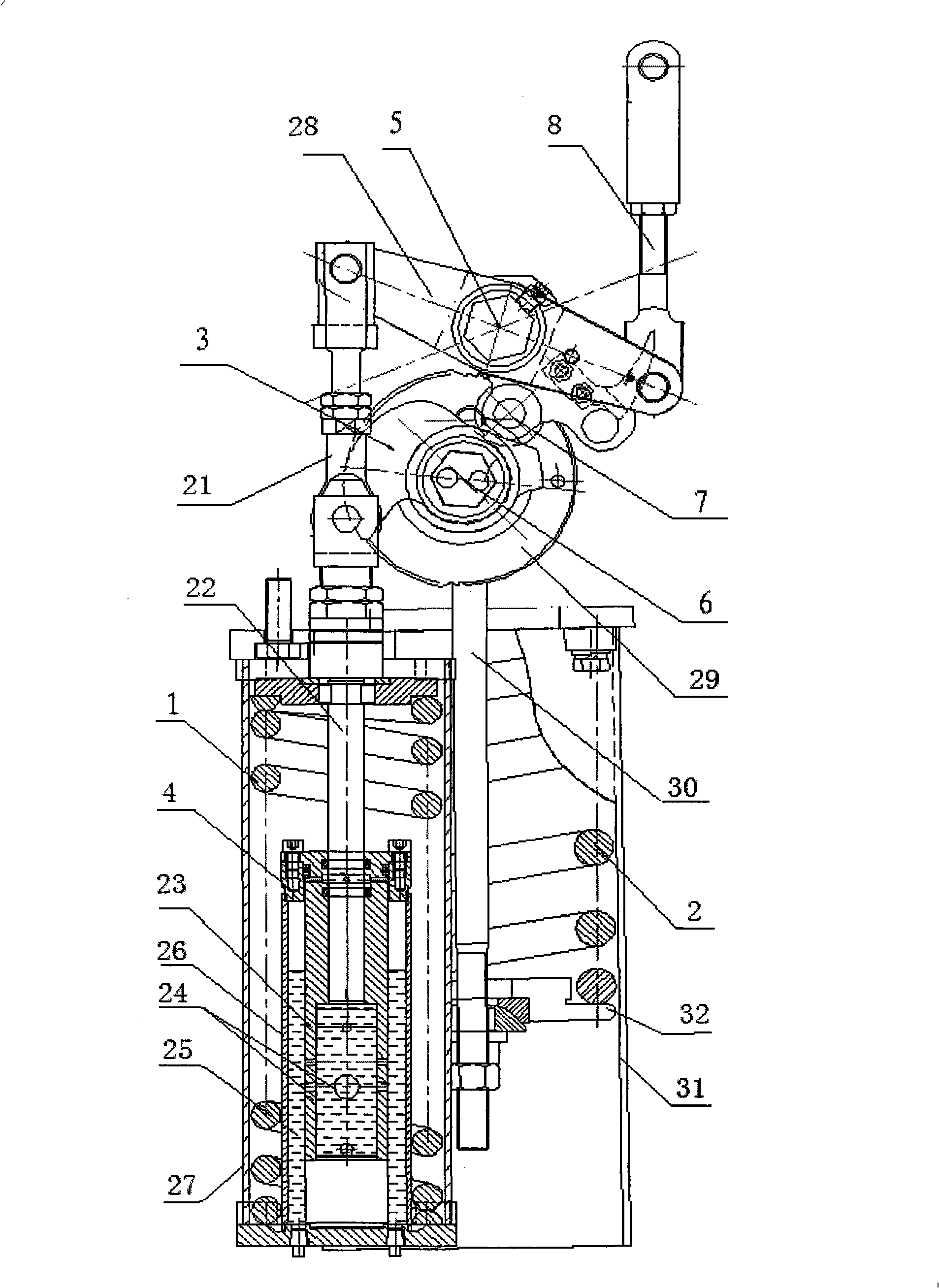

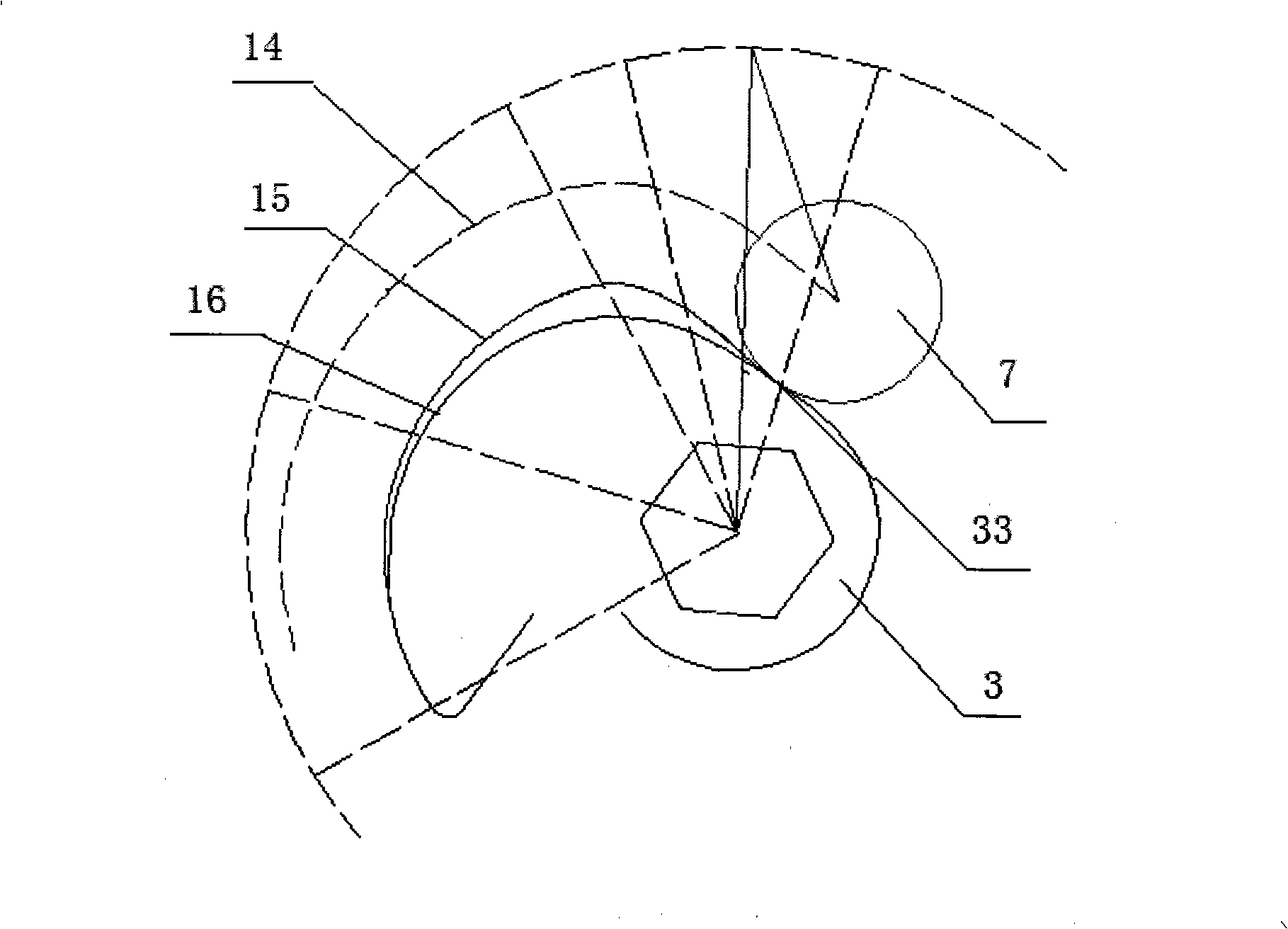

[0015] refer to figure 1 As shown, a buffer 4 is placed inside the opening spring 1, and the opening spring 1 is connected to the output shaft 5 on one side of the outer toggle arm to drive the output shaft 5 to rotate, and the other side of the outer toggle arm is connected to the mechanism pull rod 8. The closing spring 2 is connected with the energy storage shaft 6 to drive the cam 3 to rotate, and the cam 3 is in contact with the roller 7 on the output shaft 5 . The spring operating mechanism is connected to the crank arm on the intermediate phase main shaft 9 of the circuit breaker through the mechanism pull rod 8, and the intermediate phase main shaft 9 drives the other two-phase main shafts to rotate through the horizontal pull rod 33. Three-phase insulating pull rods 10 are respectively connected to the main shaft arms of each phase, and the other end is connected to the moving contact 12 through the contact spring 11, and the static contact 13 is fixed, so that the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com