Fuel injector having a solenoid valve with a spherical seat

A fuel injector and fuel injection technology, which is applied in the direction of fuel injection devices, special fuel injection devices, charging systems, etc., can solve the problems of electromagnetic valve wear and electromagnetic valve influence, etc., to reduce bouncing and improve damping characteristics , The effect of valve coordination improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

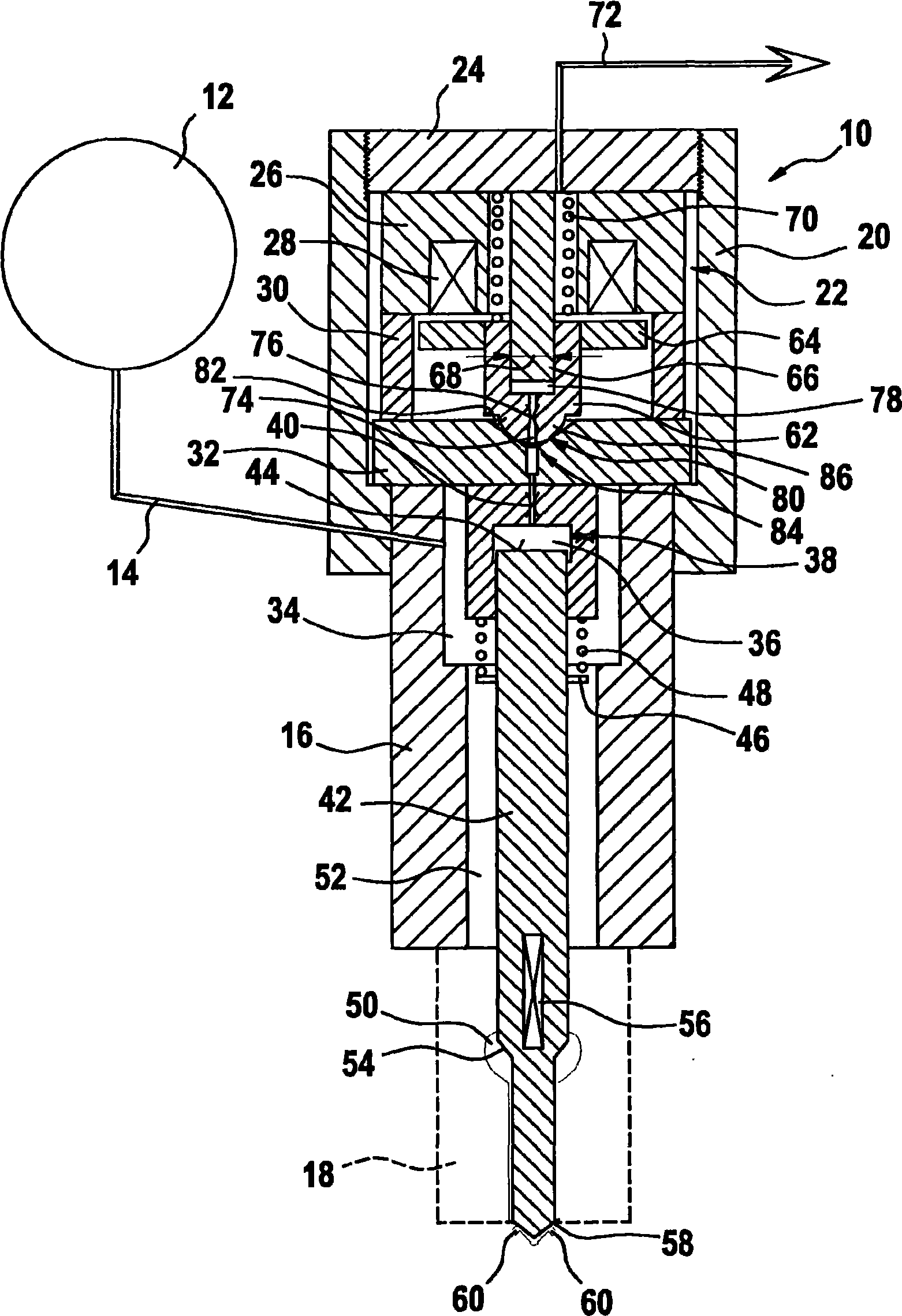

[0013] It can be seen from the figure that the fuel injector 12 passes through a system pressure p sys The pressure accumulator 12 is charged with fuel under high pressure. System pressure p in pressure accumulator 12 sys It is generated by a high-pressure delivery device (not shown in the figure), such as a high-pressure pump, and passes from the pressure accumulator 12 via the high-pressure line 14 to the fuel injector 10 . The high-pressure line 14 leads into the injector housing 16 and applies the pressure chamber indicated by reference numeral 34 at the system pressure p sys under system pressure.

[0014] According to the figure, the fuel injector 10 comprises, in addition to the injector housing 16, a nozzle body 18 which is only dotted here and an actuator housing 20, in which an actuator configured as a solenoid valve 22 is mounted. mechanism. The actuator housing 20 is closed by a housing cover 24 . In this figure the housing cover 24 is provided with an externa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com