Low-ash coal-based activated carbon quick activation production technology

A production process and activated carbon technology, which is applied in the field of rapid activation production process of low-ash coal activated carbon, can solve problems such as affecting the quality of product activated carbon, difficult activation, and increased ash content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

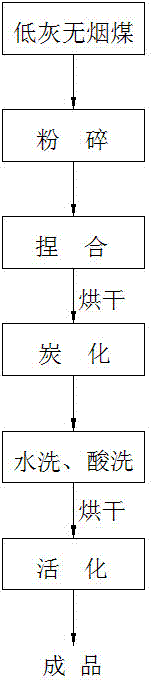

[0017] Such as figure 1 As shown, its technological process is:

[0018] 1) Pulverization: Pulverize the cleaned Taixi coal to coal powder of less than 200 mesh, and then add industrial NaOH and Ca(NO 3 ) 2 , after mixing evenly, add coal tar and knead, press into shape, dry, and enter the carbonization furnace for carbonization;

[0019] 2) Kneading and carbonization: the above-mentioned uniformly mixed coal powder is kneaded with coal tar according to the existing process, pressed into shape, dried, and then enters the carbonization furnace for carbonization;

[0020] 3) Water washing, pickling, activation: Soak the carbonized material in hot water at 60°C, wash for 60 minutes to remove floating ash, then soak in dilute hydrochloric acid with a mass fraction of 5% for 80 minutes, wash with water and take out the activated carbon , drying, and activation are finished products.

[0021] In the carbonization process of the above-mentioned embodiment, the ash mainly composed...

Embodiment 1—7

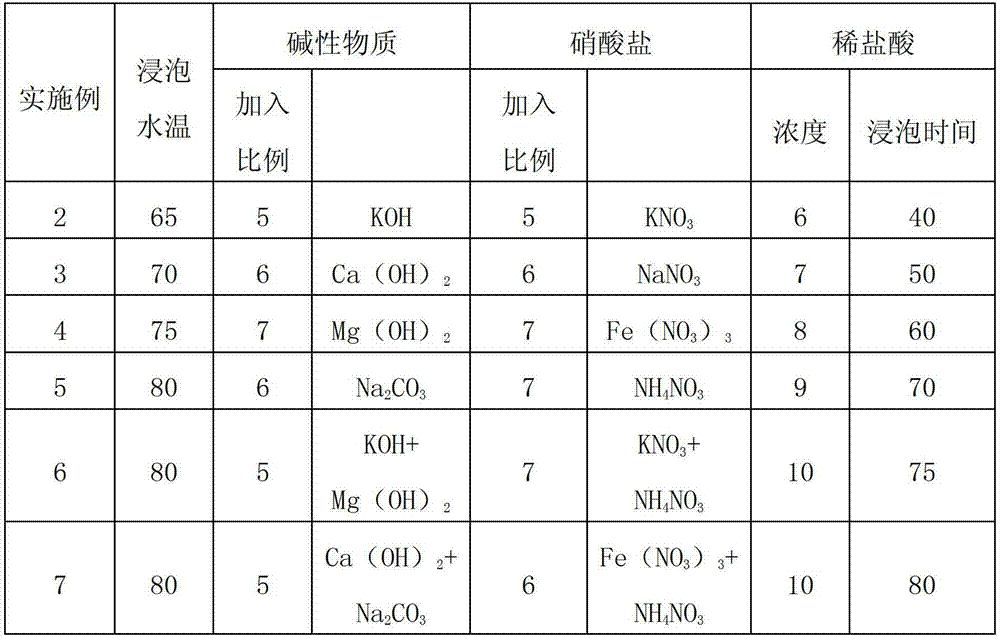

[0035] On the basis of above-mentioned embodiment 1, change following condition:

[0036]

[0037] In the above examples, the alkaline substances are NaOH, KOH, Ca(OH) 2 , Mg(OH) 2 、Na 2 CO 3 One or a mixture of two or more in any proportion, the nitrate is Ca (NO 3 ) 2 、KNO 3 、NaNO 3 , Fe (NO 3 ) 3 , NH 4 NO 3 One or a mixture of two or more in any proportion, the above-mentioned alkaline substances and nitrates are of industrial purity.

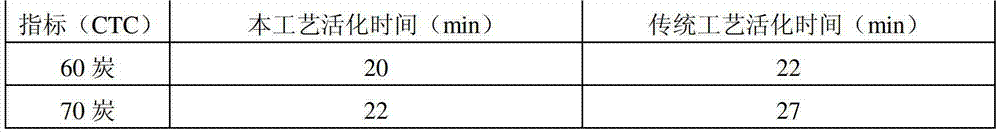

[0038] The technical indicators of CTC-60 are:

[0039]

[0040] The technical index of CTC-70 is very close to the technical index of CTC-60 mentioned above. As can be seen from the foregoing examples, compared with the prior art, the technical solution of the present invention has improved carbon tetrachloride adsorption rate (CTC), iodine adsorption value, and methylene blue adsorption value, and the ash content has decreased by about 2- About 4 percentage points, the activation time, activation energy consumption and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com