Semiconductor laser side pump module

A laser module and semiconductor technology, applied in the field of lasers, can solve problems such as water leakage, low conversion efficiency, and complex assembly, and achieve the effects of avoiding assembly errors, reducing processing difficulty, and uniform energy distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Describe the present invention in detail below in conjunction with accompanying drawing and specific implementation example:

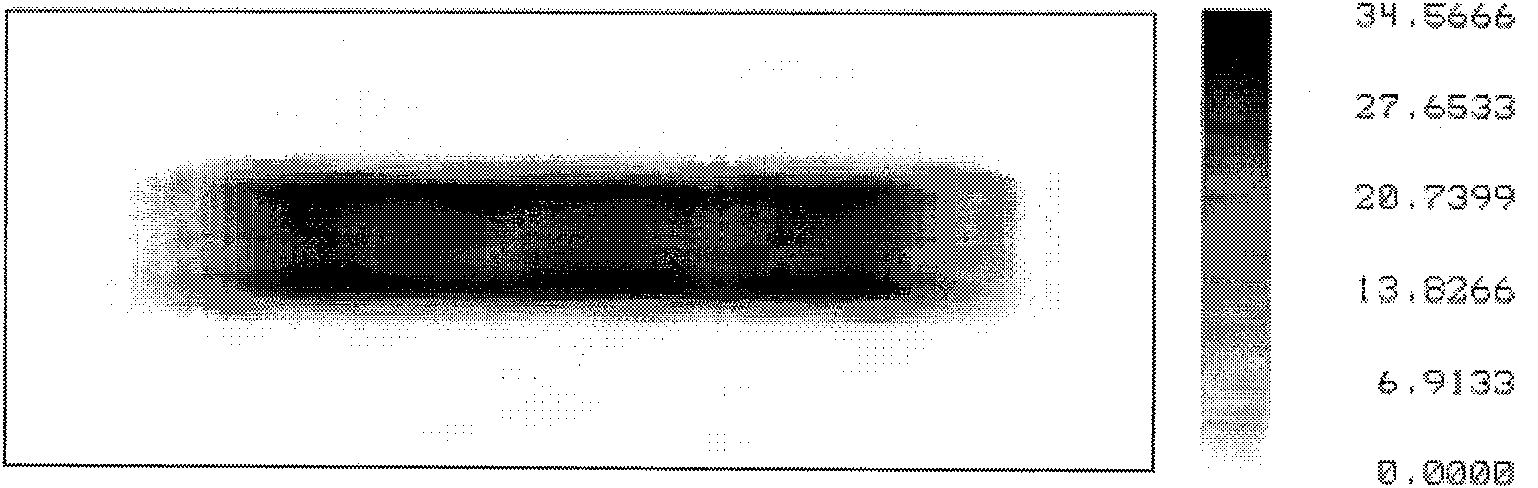

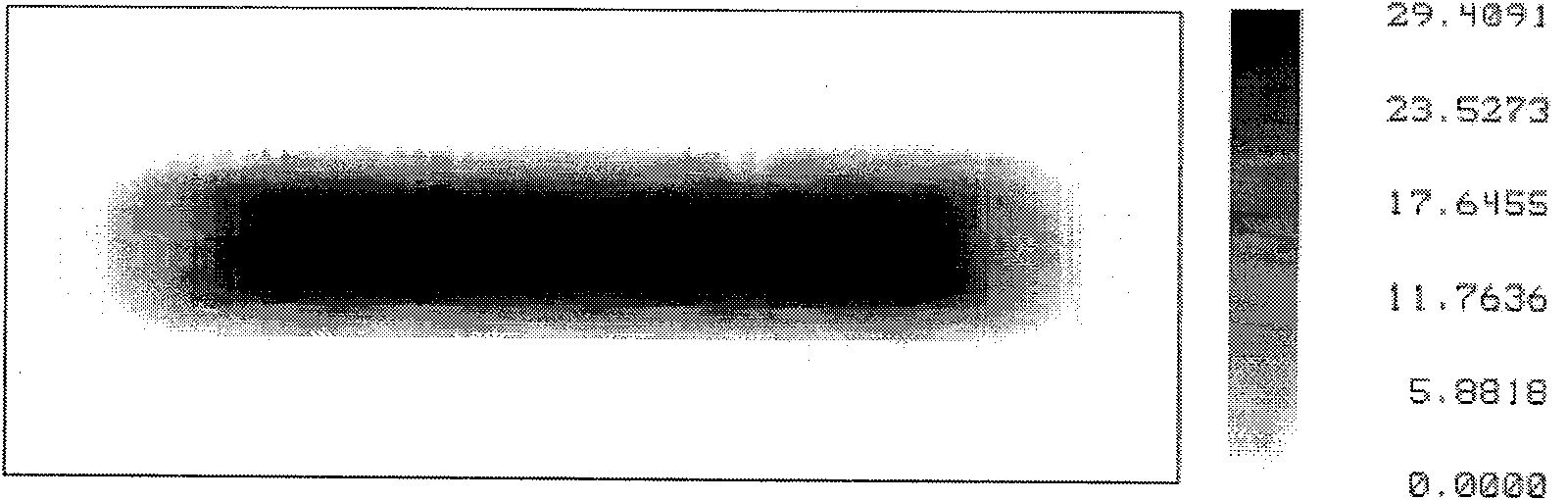

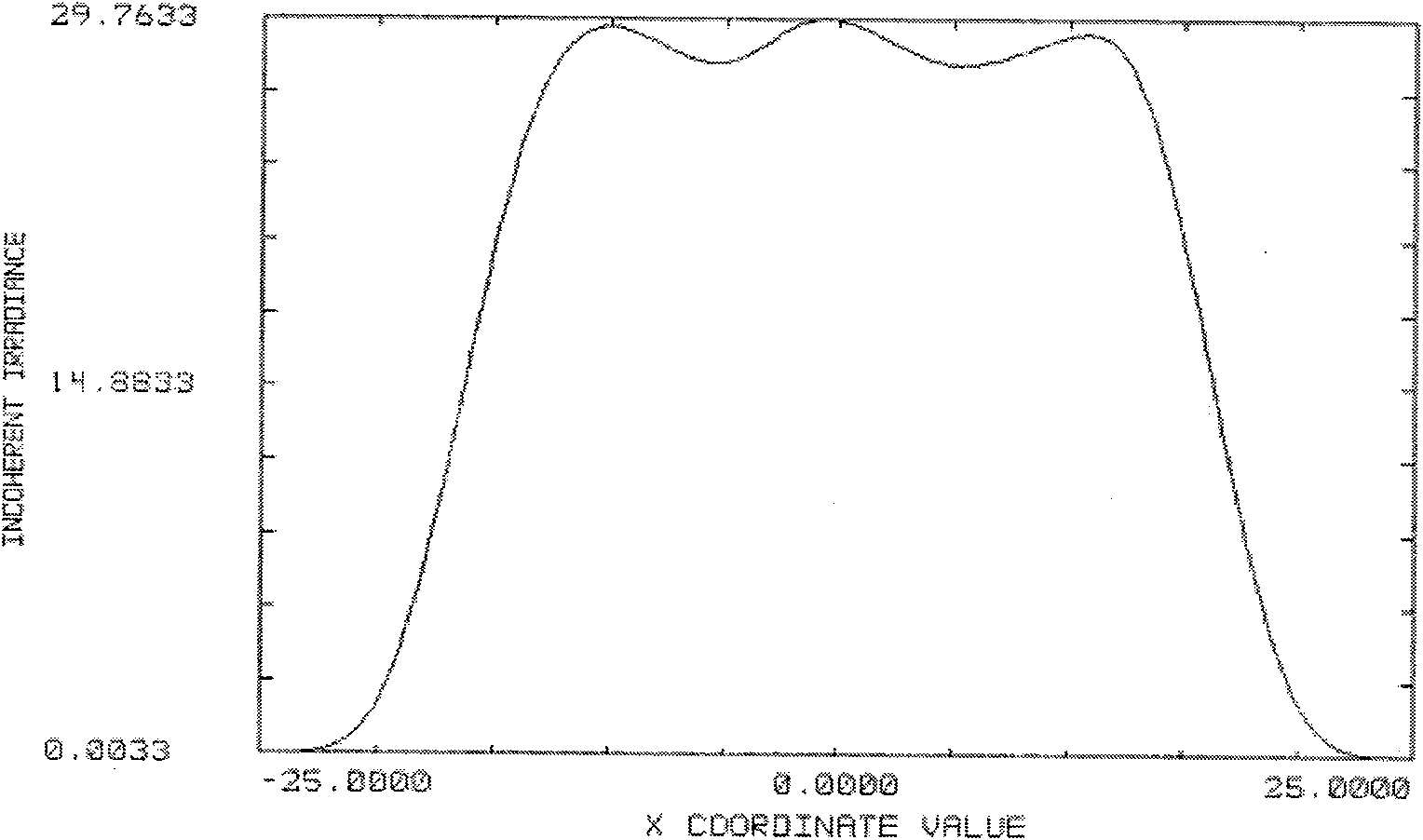

[0034] see image 3 and Figure 4 , the semiconductor laser side pump module of the present invention mainly includes a semiconductor laser module 1, a fast axis collimator mirror 2, a beam expander mirror 3, a homogenizing mirror 4, a crystal rod 5, and a base plate 6 (cooperating with the main components of the present invention in addition) Some ancillary parts such as water cooling part and shell part are identical with prior art, therefore do not show in the figure). The side pump module unit is composed of semiconductor laser module 1, fast axis collimator mirror 2, beam expander mirror 3 and homogenizer mirror 4, wherein semiconductor laser module 1, fast axis collimator mirror 2, beam expander mirror 3 and homogenizer mirror 4 are all fixed on the base plate 6, the fast axis collimating mirror 2 is set at the front end of the semicondu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com