Micro-wave vacuum freeze-drying equipment

A technology of microwave vacuum and drying equipment, which is used in drying solid materials, lighting and heating equipment, and methods to dry solid materials, etc., can solve the problems of microwave shielding and vacuum sealing, deformation of thermally conductive plastics, and large heat loss. , to achieve the effect of avoiding the phenomenon of spark discharge, uniform energy distribution, and reducing the probability of microwave low-voltage discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

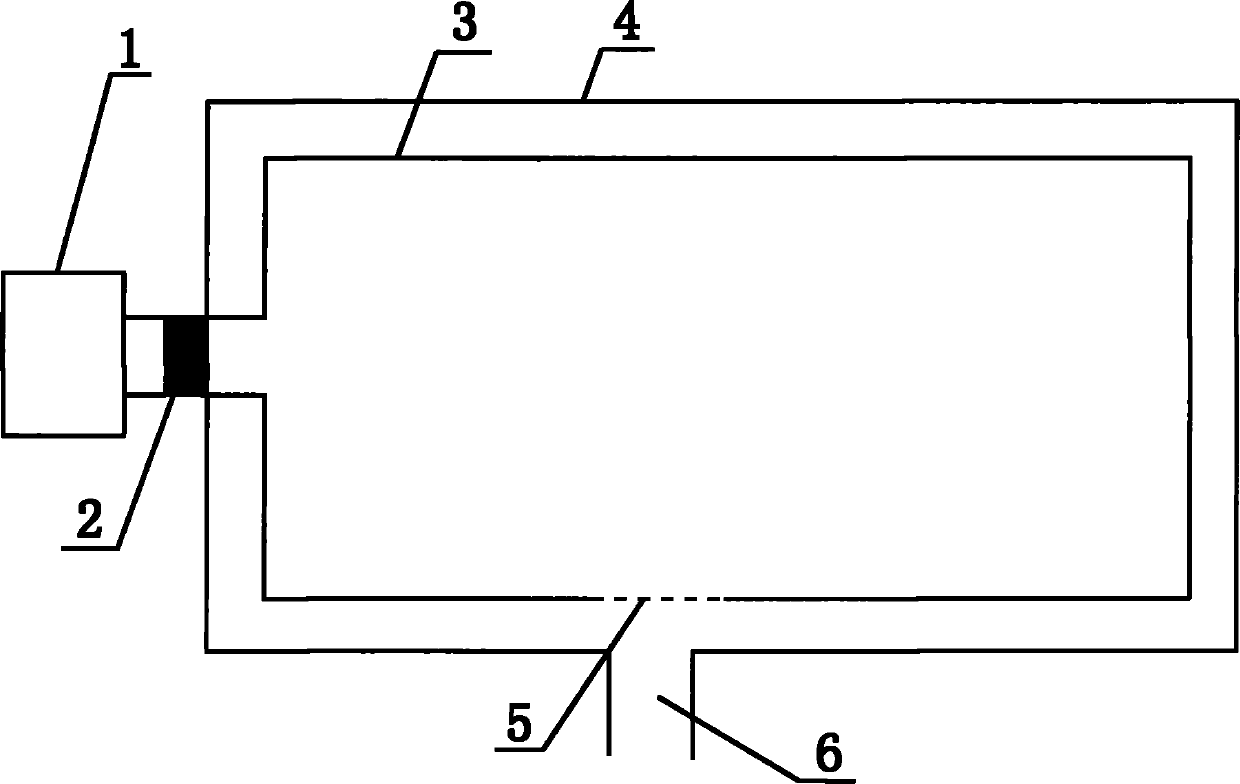

[0060] The present invention is based on the ordinary freeze-drying process technology, changing the way of providing the latent heat of sublimation, changing the infrared heating to microwave heating, so that the inside and outside of the material are heated at the same time, avoiding the heat transfer resistance in the freeze-drying process and reducing the heat loss. The sublimation efficiency is improved, the freeze-drying time is shortened, and the drying cost is reduced. The specific structure and principle of the present invention will be described in detail below.

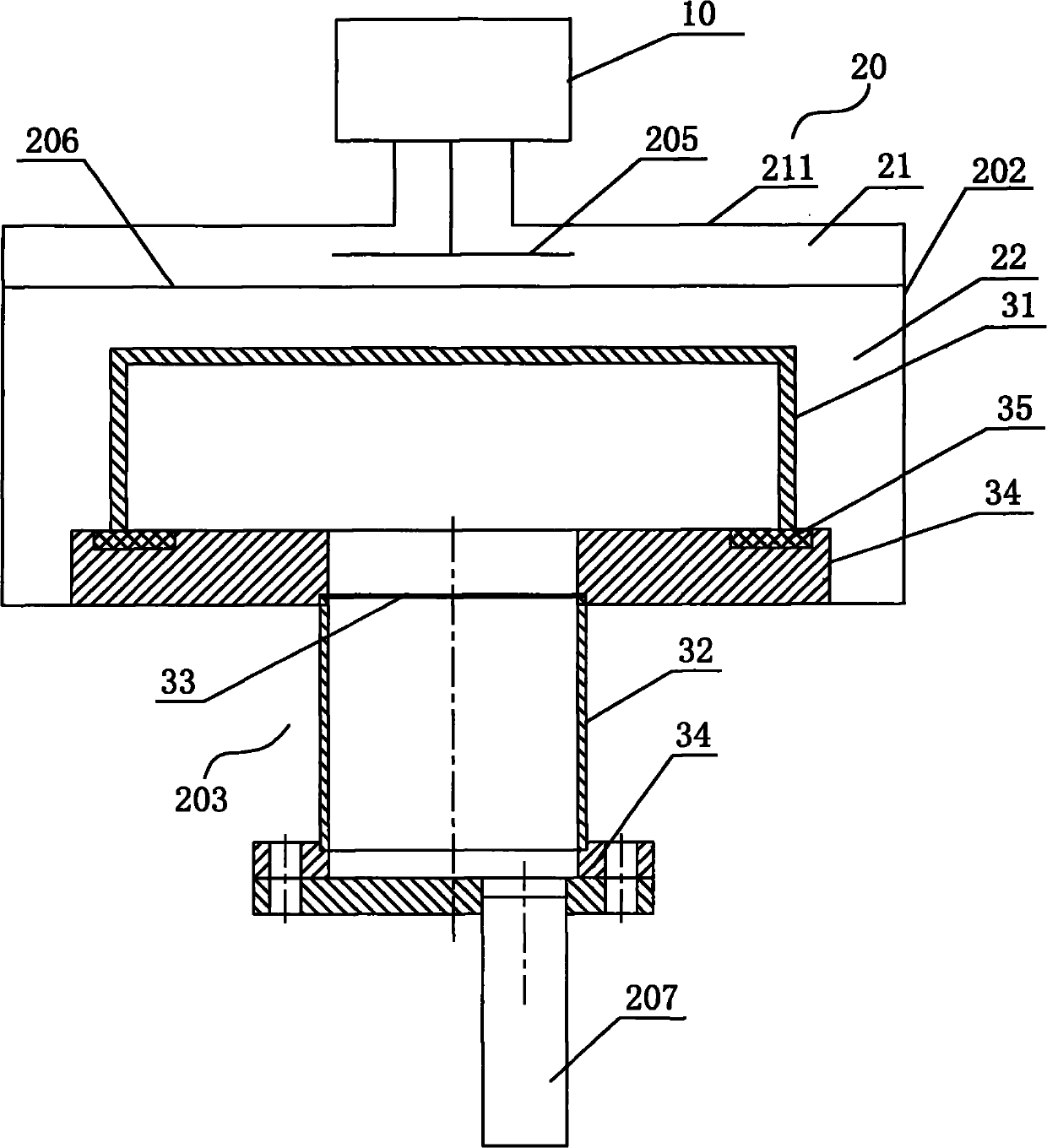

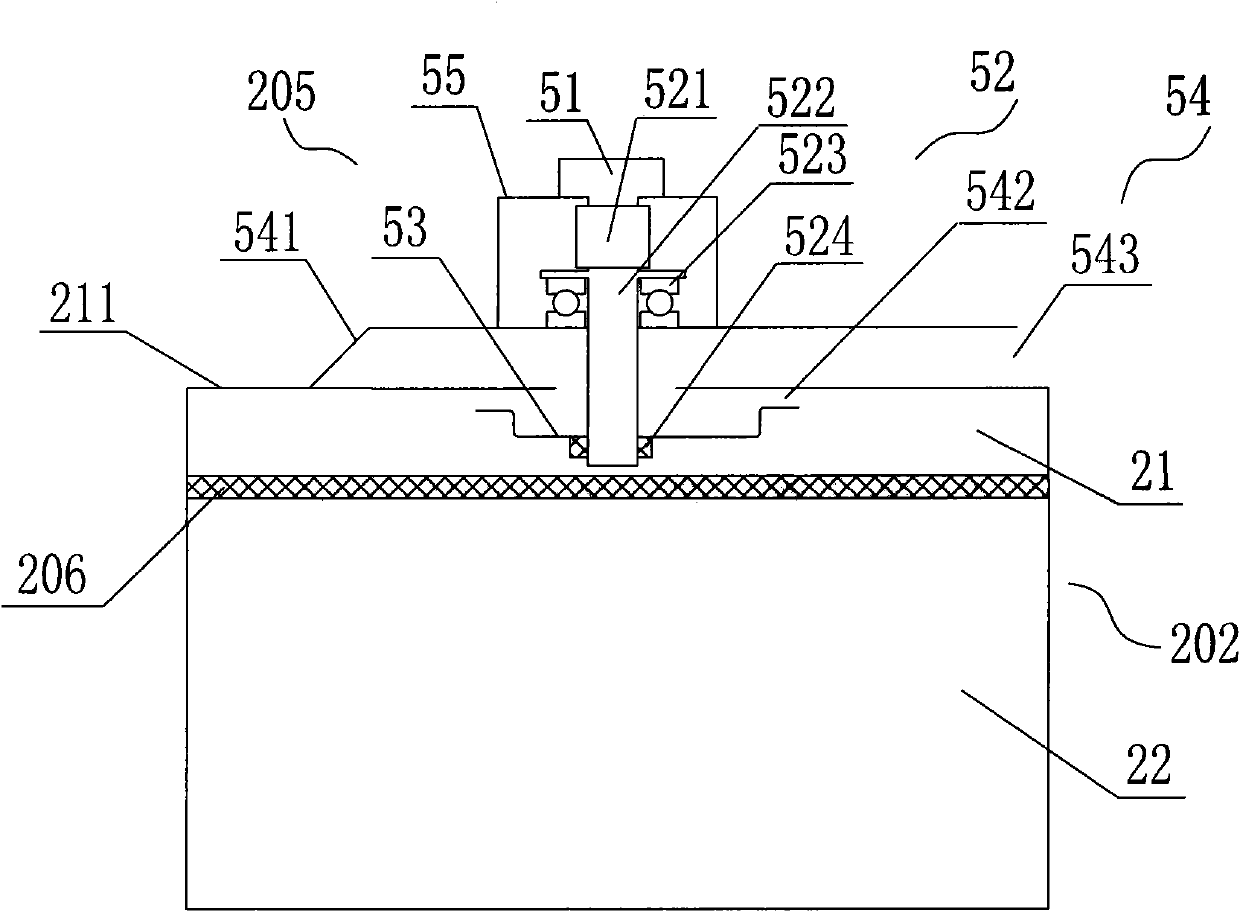

[0061] see figure 2 , figure 2 It is a structural schematic diagram of an embodiment of the present invention. The microwave vacuum freeze-drying equipment of the present invention includes a microwave power source 10 and a microwave vacuum freeze-drying device 20, the microwave power source 10 is connected with the microwave vacuum freeze-drying device 20, and the microwave vacuum freeze-drying device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com