High-sensitivity fast on-line detection method of optical thin film and element surface laser-induced damage

An optical film and detection method technology, applied in the direction of optical testing flaws/defects, etc., can solve the problems of unsatisfactory detection sensitivity, influence of uniformity and stability of imaging illumination light source, weak illumination intensity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

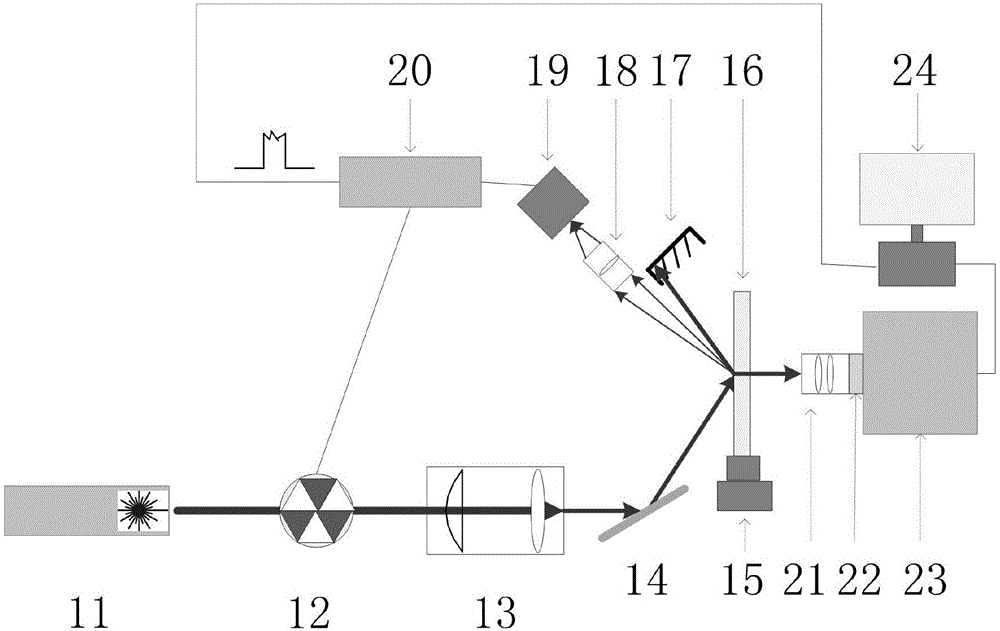

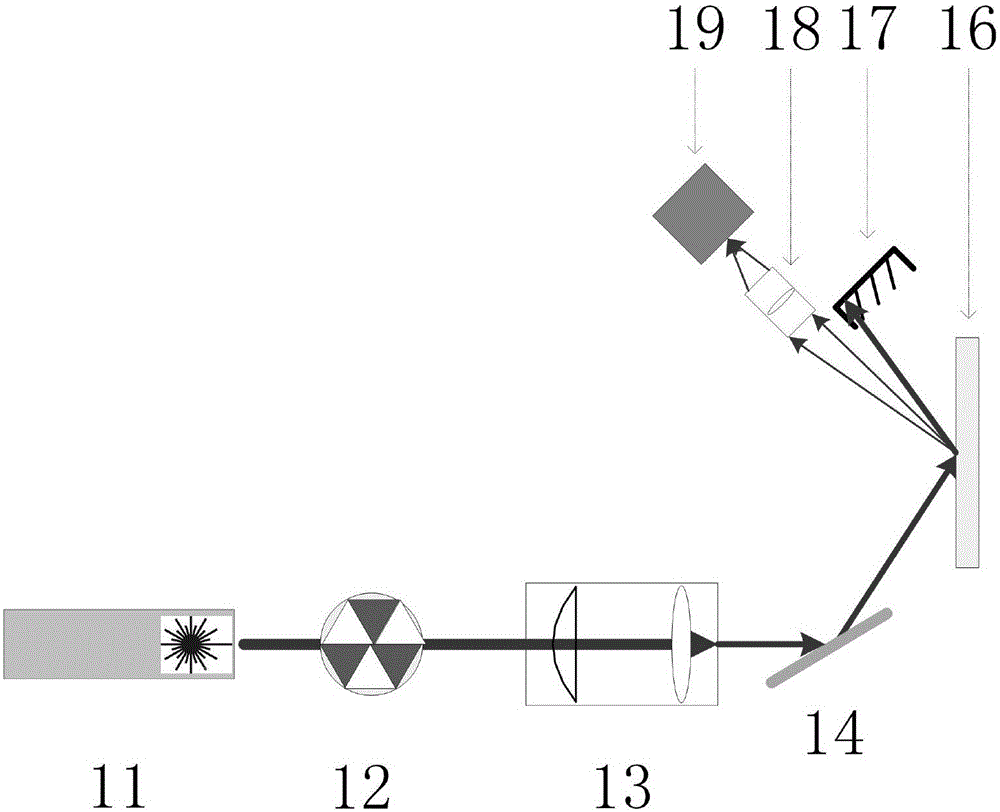

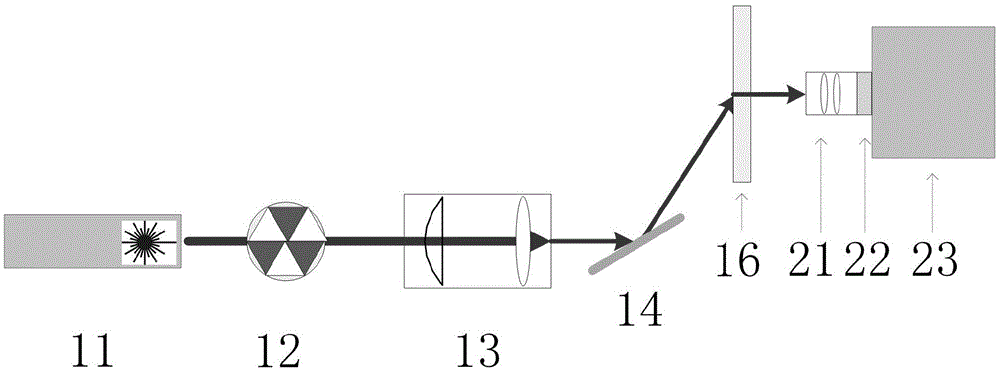

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0021] The high-sensitivity fast on-line detection method of laser damage on the surface of the optical film and components of the present invention uses the He-Ne light scattering detection method realized by the He-Ne light scattering detection device as the main detection method, and the microscopic detection method realized by the online microscopic CCD detection device. The CCD imaging detection method is used as an auxiliary detection method. For each test sample point, the He-Ne light scattering detection method is firstly used as the basis for the identification of laser damage on the surface of the optical film and the component. If the detection of the He-Ne light scattering detection method The results show that the optical film and the surface of the component are damaged, then suspend the He-Ne light scattering detection method, re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com