Vacuum freeze-drying tester

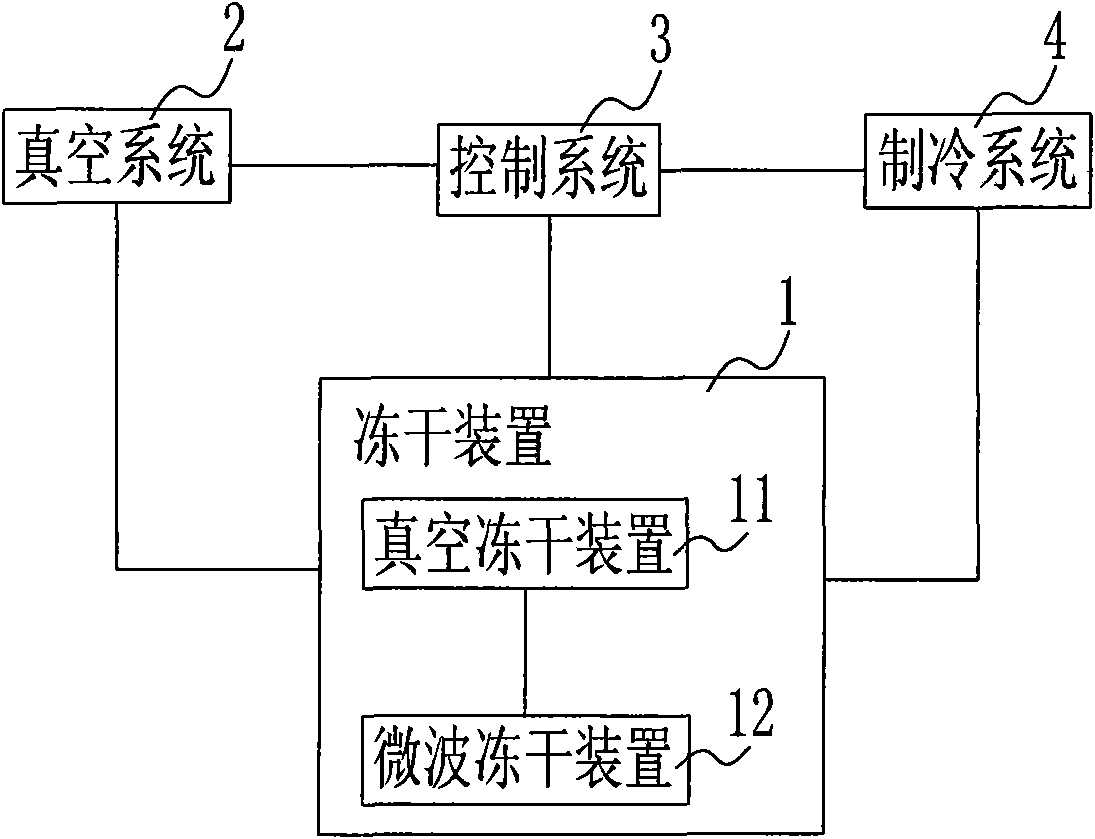

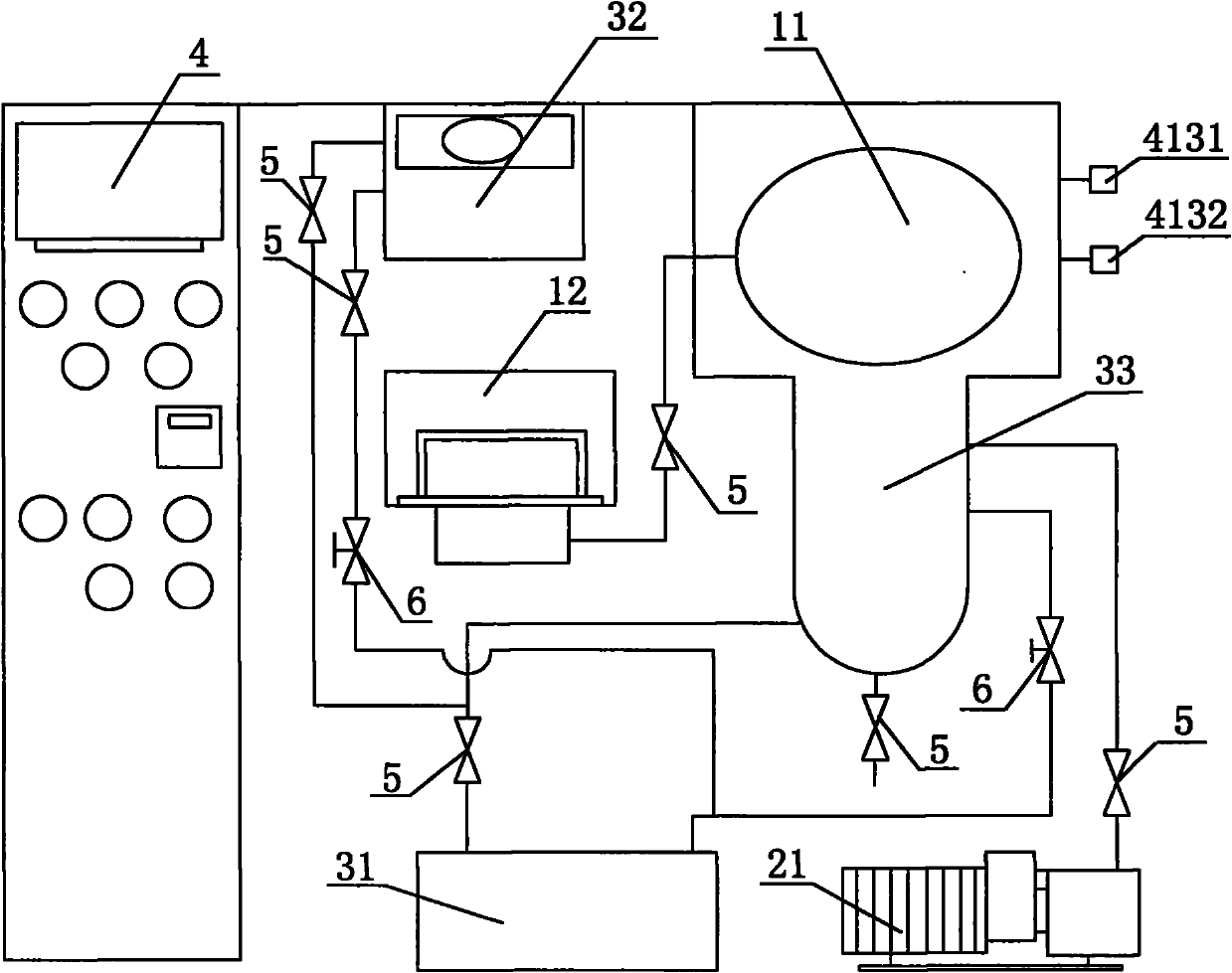

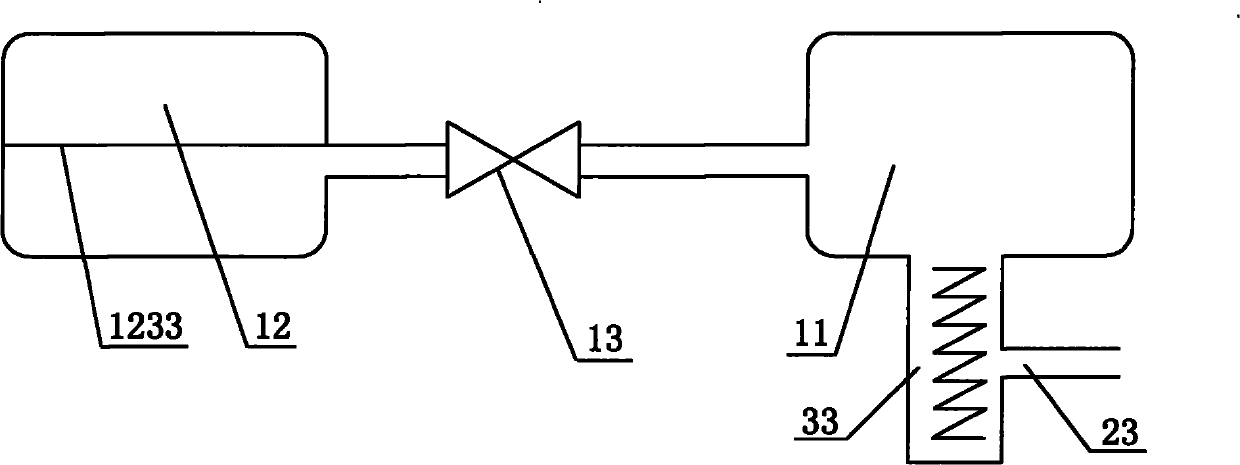

A vacuum freeze-drying and experimental machine technology, which is applied in the direction of dryers, drying solid materials, and method combinations to dry solid materials, etc., can solve problems such as melting, incompletely solving microwave shielding and vacuum sealing, and large heat loss. Avoid sparking discharge, facilitate comparative analysis and comparison of related parameters, and achieve uniform energy distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0135] Example: Take 500g of fresh winter jujube, after selection, cleaning and pitting, take 320g of hollow jujube for color protection, then move it into a common vacuum freeze-drying warehouse to evacuate, set the heating curve at the same time, set the temperature of the heating plate to 130°C, wait When the vacuum degree falls within the range of 3000-3500Pa, turn on the heating switch, start the heating curve, and heat and dry under vacuum. The drying time is about 3.7 hours, and 75.4g of dried dates are obtained with a moisture content of 16.2%.

[0136] 2. Microwave vacuum drying:

[0137] Operation process: (1) Start the compressor to lower the cold trap below -35°C;

[0138] (2) The preset vacuum pressure is 3000Pa, start the vacuum pump;

[0139] (3) Start the microwave power source, and adjust the value of microwave power (within 300-500W) according to the requirements of material characteristics and dryness. The microwave vacuum drying time is generally 0.5 to 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com