PtM/C electrocatalyst for fuel cell and preparation method of PtM/C electrocatalyst for fuel cell

An electrocatalyst and fuel cell technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of not too high a loading capacity, poor particle size distribution uniformity, long preparation period of colloid method, etc., and achieve good oxygen reduction The effect of reaction catalytic performance, good thermal stability and small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

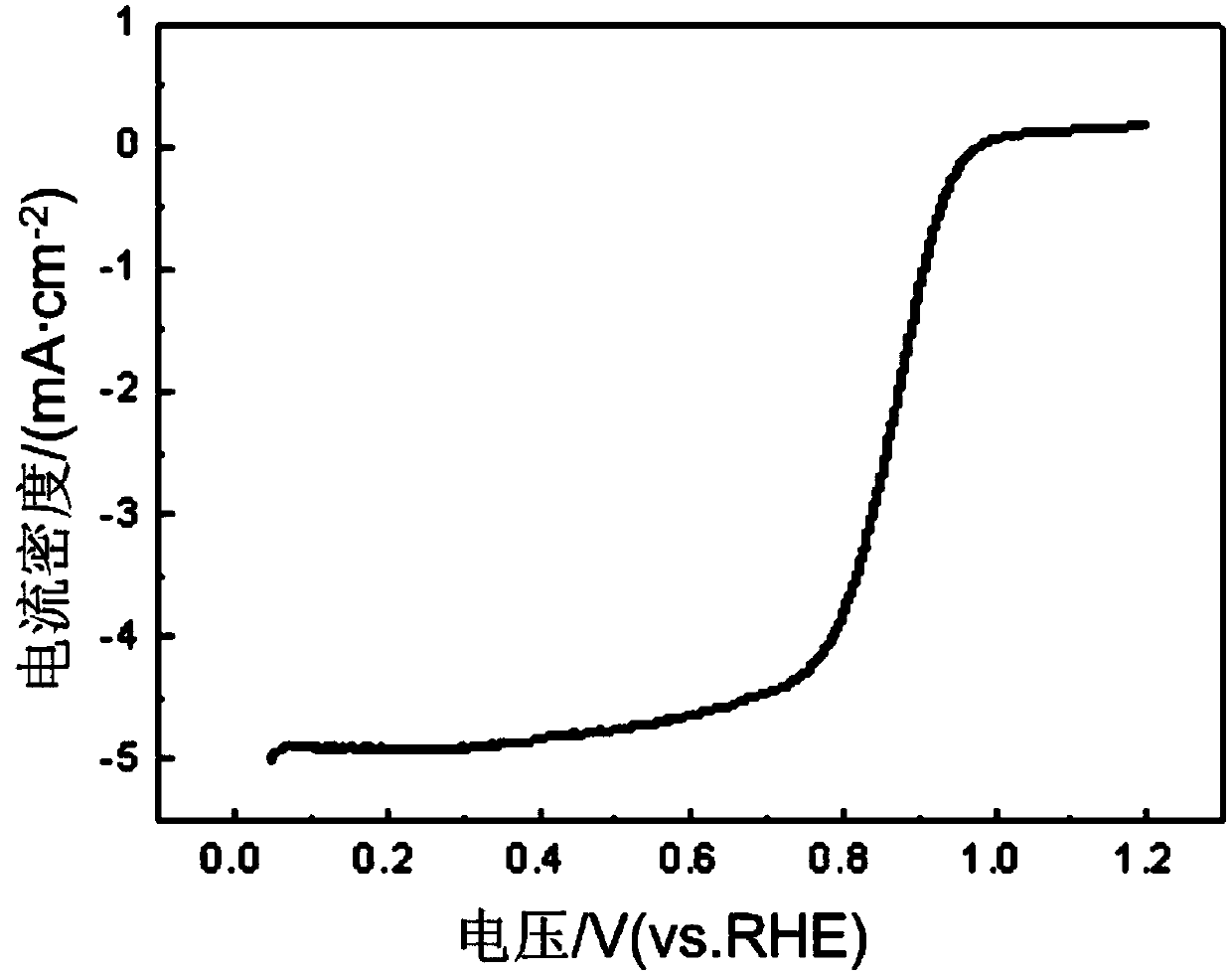

[0033] In this example, Pt was prepared by pulsed microwave assisted chemical reduction 3 Ni / XC-72 electrocatalyst (Pt to Ni molar ratio 3:1, Pt 3 The percentage of Ni accounting for the total mass of the catalyst is 20%, then the percentage of Pt accounting for the total mass of the catalyst is 18.18%, and the percentage of Ni accounting for the total mass of the catalyst is 1.82%). The specific preparation method is as follows:

[0034] (1) According to the mass ratio of Vulcan XC-72 carbon black (Cabot, USA) to ethylene glycol is 1:200, add Vulcan XC-72 to ethylene glycol, and stir evenly with ultrasonic to prepare suspension A;

[0035] (2) by the mol ratio of Ni in nickel nitrate and Pt in chloroplatinic acid is 1: 3, chloroplatinic acid and nickel nitrate are joined in the suspension A that step (1) makes together, wherein, chloroplatinic acid and The mass ratio of Vulcan XC-72 is controlled to be 1:1.66, the ultrasonic stirring is uniform, the pH value of the solution ...

Embodiment 2

[0041] In this example, Pt was prepared by pulsed microwave assisted chemical reduction 3 Ni / acetylene black electrocatalyst (Pt to Ni molar ratio 3:1, Pt 3 The percentage of Ni accounting for the total mass of the catalyst is 20%, then the percentage of Pt accounting for the total mass of the catalyst is 18.18%, and the percentage of Ni accounting for the total mass of the catalyst is 1.82%). The specific preparation method is as follows:

[0042] (1) According to the mass ratio of acetylene black (Alfa, USA) to ethylene glycol is 1: 200, acetylene black is added to ethylene glycol, and ultrasonically stirred evenly to obtain suspension A;

[0043](2) by the mol ratio of Ni in nickel nitrate and Pt in chloroplatinic acid is 1: 3, chloroplatinic acid and nickel nitrate are joined in the suspension A that step (1) makes together, wherein, chloroplatinic acid and The mass ratio of acetylene black is controlled to be 1:1.66, the ultrasonic stirring is uniform, the pH value of th...

Embodiment 3

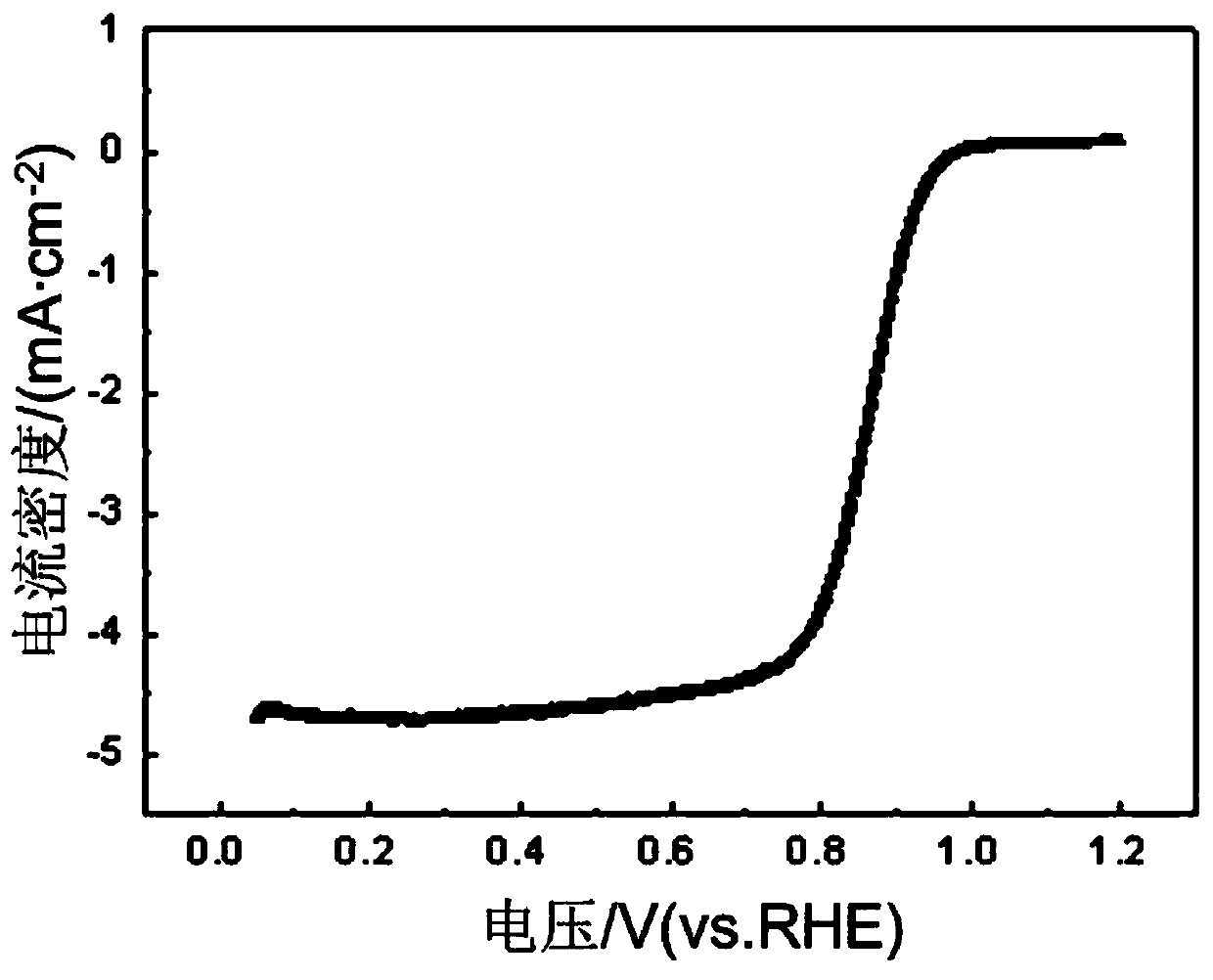

[0048] In this example, Pt was prepared by pulsed microwave assisted chemical reduction 3 Fe / XC-72 electrocatalyst (Pt to Fe molar ratio 3:1, Pt 3 The percentage of Fe accounting for the total mass of the catalyst is 20%, then the percentage of Pt accounting for the total mass of the catalyst is 18.26%, and the percentage of Fe accounting for the total mass of the catalyst is 1.74%). The specific preparation method is as follows:

[0049] (1) According to the mass ratio of Vulcan XC-72 and ethylene glycol as 1:300, add Vulcan XC-72 to ethylene glycol, and stir evenly with ultrasonic to prepare suspension A;

[0050] (2) by the molar ratio of Fe in ferric nitrate and Pt in chloroplatinic acid is 1: 3, chloroplatinic acid and ferric nitrate are joined in the suspension A that step (1) makes together, wherein, chloroplatinic acid and The mass ratio of Vulcan XC-72 is controlled to be 1:1.66, the ultrasonic stirring is uniform, the pH value of the solution is adjusted to 10, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com