Microwave-assisted enzymatic extraction process of tea polyphenol

A microwave-assisted, enzymatic extraction technology, applied in the chemical industry, sustainable manufacturing/processing, climate sustainability, etc., can solve the problems of large use of organic solvents, solvent residues, etc., to improve purity, promote dissolution, and improve efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

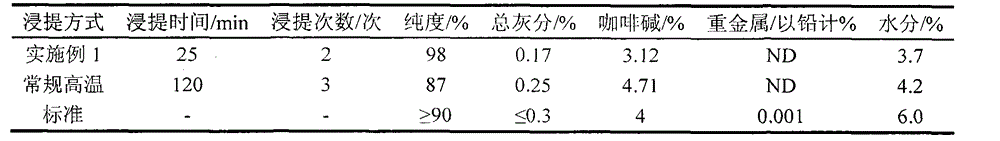

Embodiment 1

[0027] a) Impurity removal and cleaning: select fresh green tea leaves, remove impurities such as wood chips and branches, wash the dust on the surface of the tea leaves with clean water, drain the surface water, and set aside;

[0028] b) Pulverization of tea leaves: take the tea leaves in step a) and pulverize them to 30 mesh sieves with a pulverizer for subsequent use;

[0029] c) Adjust liquid and add enzyme: add pure water according to the material-to-liquid ratio of 1:13, adjust the tea pH to 4.0 after mixing evenly, stir evenly, add compound enzyme liquid according to 0.1% of the tea quality, stir evenly, and set aside; The enzyme is a mixture of cellulase and pectinase according to the enzyme activity of 1:1;

[0030] d) Vacuum microwave treatment: place the substance in step c) in a vacuum microwave oven, adjust the vacuum degree to -0.090 ~ -0.080MPa, and use pulse microwave treatment for microwaves. Under the condition of pulse microwave dose of 0.01kw / kg, the pulse...

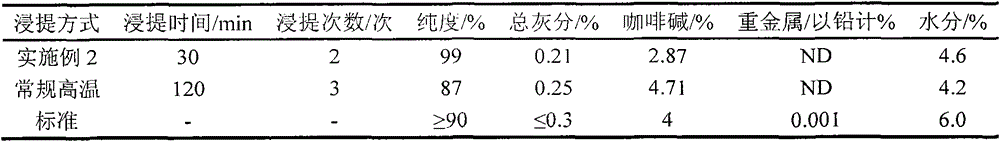

Embodiment 2

[0041] a) Impurity removal and cleaning: select fresh green tea leaves, remove impurities such as wood chips and branches, wash the dust on the surface of the tea leaves with clean water, drain the surface water, and set aside;

[0042] b) Pulverization of tea leaves: take the tea leaves in step a) and pulverize them to a 40-mesh sieve with a pulverizer for subsequent use;

[0043] c) Adjust liquid and add enzyme: add pure water according to the material-to-liquid ratio of 1:15, adjust the pH of the tea to 5.0 after mixing evenly, stir evenly, add compound enzyme liquid according to the mass of 0.25%, stir evenly, and set aside; wherein, the compound enzyme It is prepared by mixing cellulase and pectinase according to the enzyme activity of 1:1;

[0044] d) Vacuum microwave treatment: put the substance in step c) in a vacuum microwave oven, adjust the vacuum degree to -0.090 ~ -0.080MPa, the microwave used is pulse microwave, the dose of pulse microwave is 0.04kw / kg, and the pul...

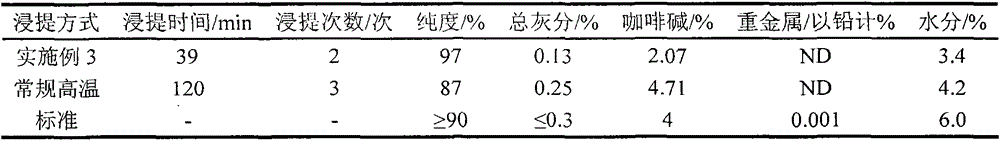

Embodiment 3

[0055] a) Impurity removal and cleaning: select fresh green tea leaves, remove impurities such as wood chips and branches, wash the dust on the surface of the tea leaves with clean water, drain the surface water, and set aside;

[0056] b) Pulverization of tea leaves: take the tea leaves in step a) and pulverize them to a 50-mesh sieve with a pulverizer for subsequent use;

[0057] c) Adjust liquid and add enzyme: add pure water according to the ratio of material to liquid 1:18, adjust the pH of tea water to 5.5 after mixing evenly, stir evenly, add compound enzyme liquid according to the mass of 0.4%, stir evenly, and set aside; wherein, the compound enzyme It is prepared by mixing cellulase and pectinase according to the enzyme activity of 1:1;

[0058] d) Vacuum microwave treatment: place the substance in step c) in a vacuum microwave oven, adjust the vacuum degree to be -0.090~-0.080MPa, the microwave used is pulse microwave, the dose of pulse microwave is 0.07kw / kg, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com