Rice processing method with essential oil mist spraying and pulse microwave action

A pulsed microwave and rice processing technology, applied in the fields of application, preservation of seeds by radiation/electric treatment, grain treatment, etc., can solve the problems of easy occurrence of insect pests and mildew, difficult to meet requirements, etc., and achieve inhibition of colony production and quality. Good, good inhibitory effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

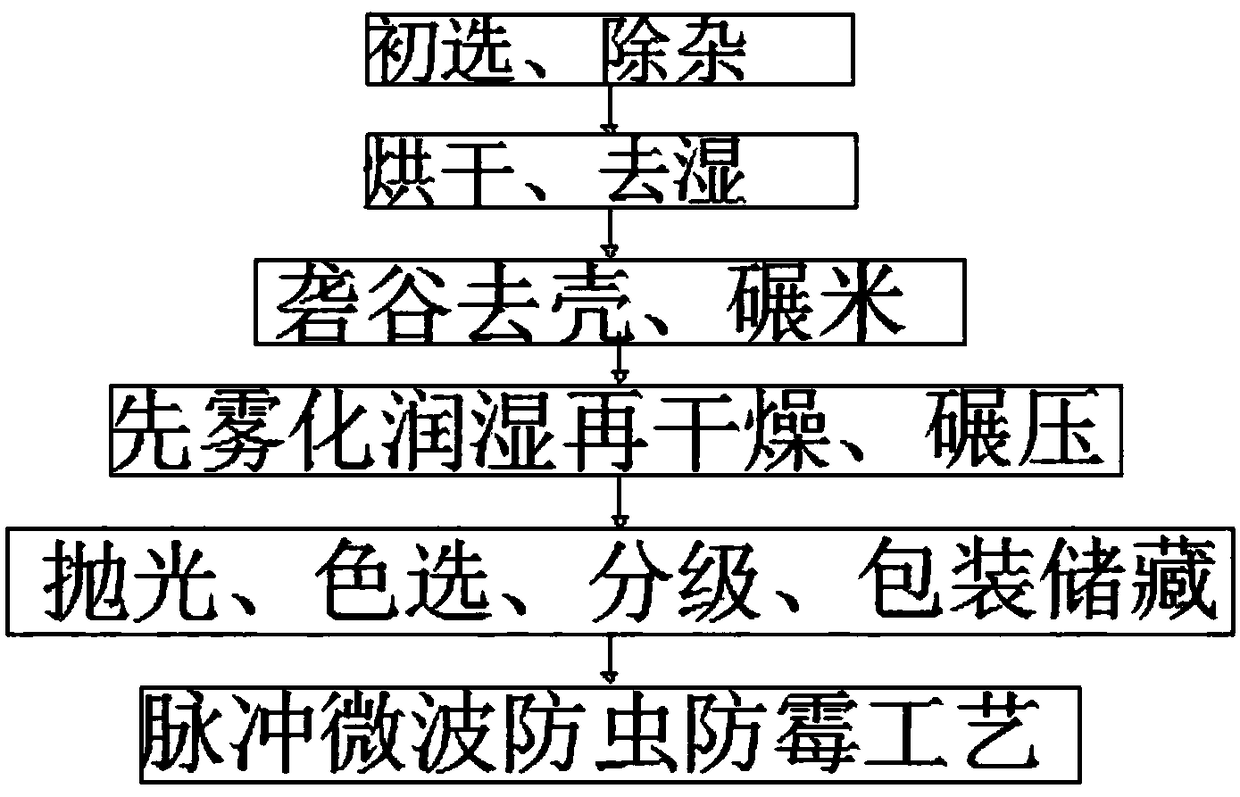

[0029] refer to Figure 1-4 , a processing technology for rice with a smooth appearance and low rate of broken rice, comprising the following steps:

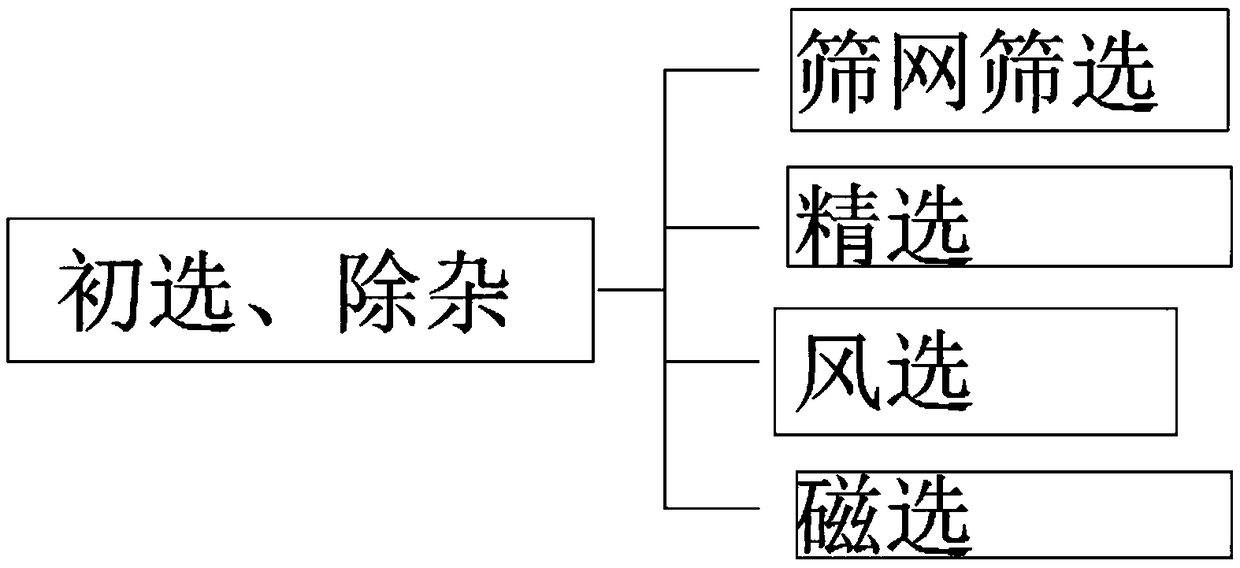

[0030] S1: Screen the harvested rice. First, according to the different width and thickness of the rice and impurities, select a screening machine with a suitable sieve hole to screen out impurities different in size from the grain, and then select, according to the difference in length between the rice and impurities Carry out separation, and then continue winnowing, the light impurities (such as chaff, rice straw, non-solid grains) are taken away by the wind in the ascending or horizontal airflow and separated from the rice, and finally magnetic separation is carried out to remove the mixed impurities in the rice. Magnetic metal can be removed by iron-absorbing equipment, and then the cleaned rice is spread in the drying room, and the thickness of the rice spread is 0.9-1.5cm;

[0031] S2: Through the blower fan installed in ...

Embodiment 2

[0037] refer to Figure 1-4 , a processing technology for rice with a smooth appearance and low rate of broken rice, comprising the following steps:

[0038] S1: screen the harvested rice, the screening process is consistent with that of Example 1, and then spread the screened rice in a drying room with a thickness of 0.9-1.5cm;

[0039] S2: Through the blower fan installed in the drying room, the hot air of 35-45°C is introduced to dry the spread rice, and the process is consistent with that of Example 1;

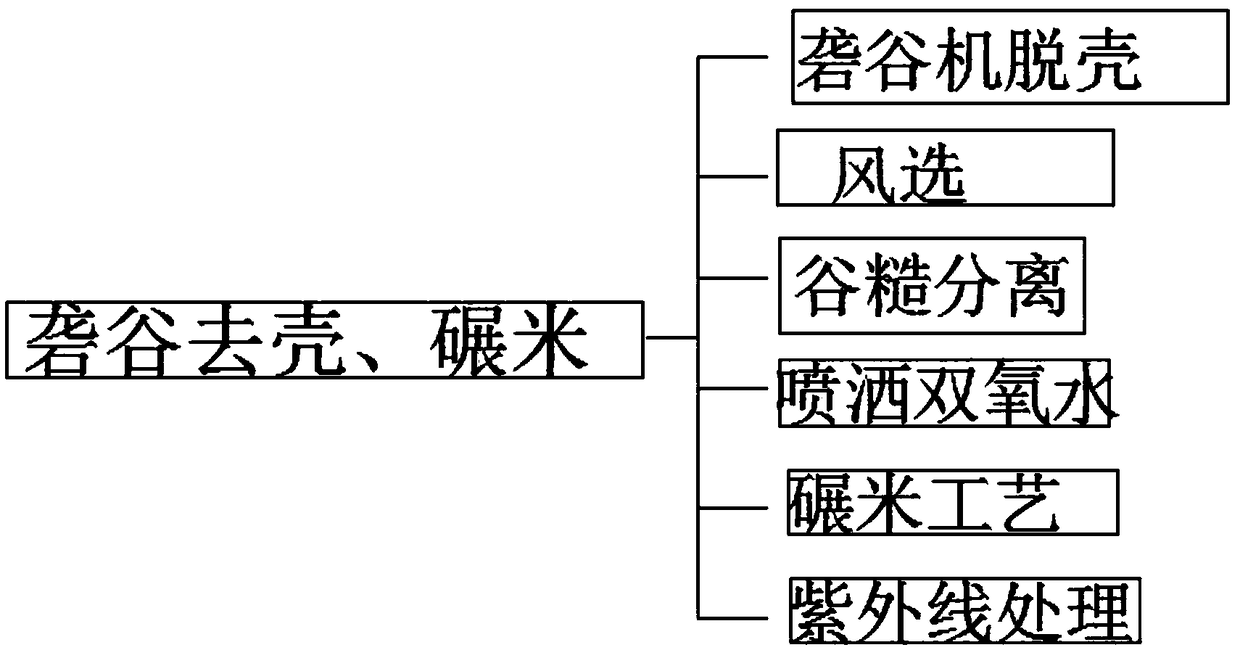

[0040] S3: Put the dried rice obtained in the process into a huller for rice hulling, and the process is consistent with that of Example 1;

[0041] S4: first atomize and moisten the semi-finished product, then put it into a rice mill and roll it again to completely shell it, cool it to room temperature, and obtain the primary rice product, the process is consistent with that of Example 1;

[0042]S5: Mix garlic essential oil and cinnamon essential oil at a volume ratio ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com