Method for extracting lithium isotope

A lithium isotope and extraction technology, which is applied to the separation of different isotopic elements, separation methods, chemical instruments and methods, etc., can solve the problems of low distribution coefficient, unfavorable extraction and separation, and increased industrialization costs, so as to achieve low cost and adaptability to industrial operations strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In the following, the embodiments of the present invention will be described in detail.

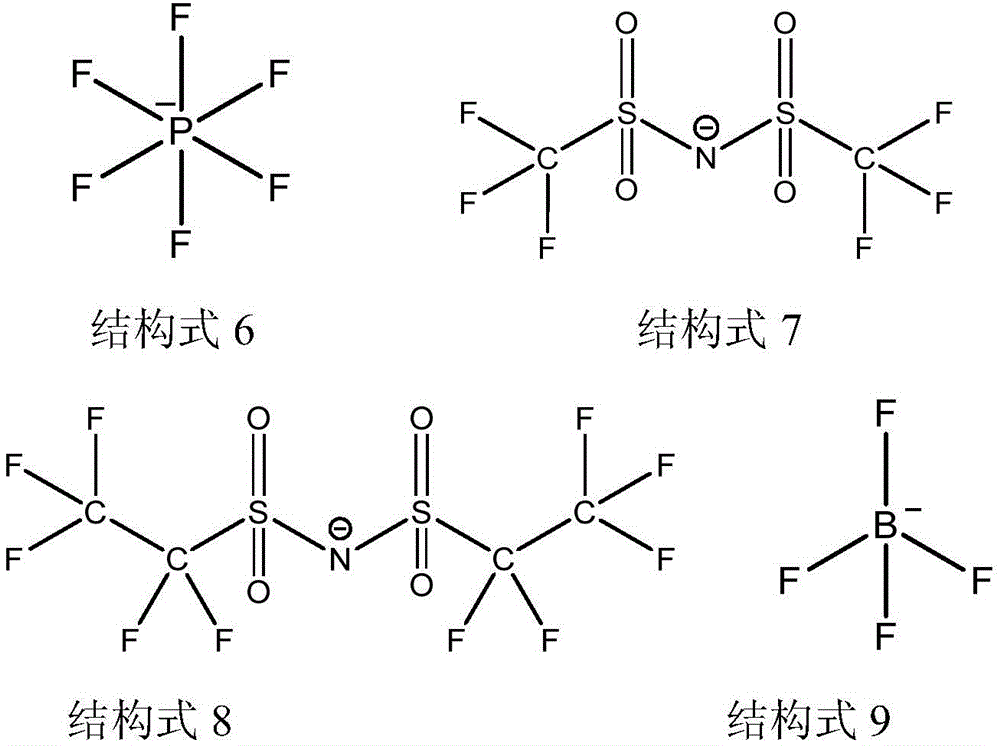

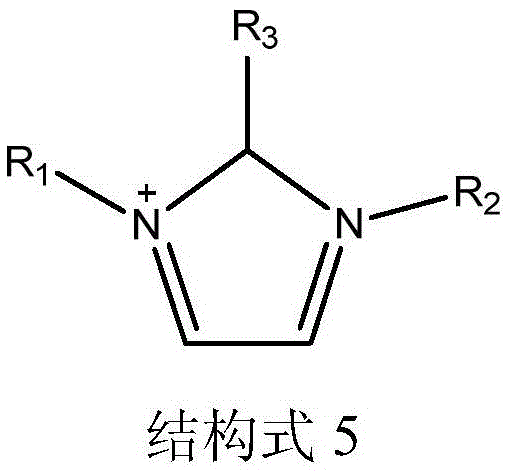

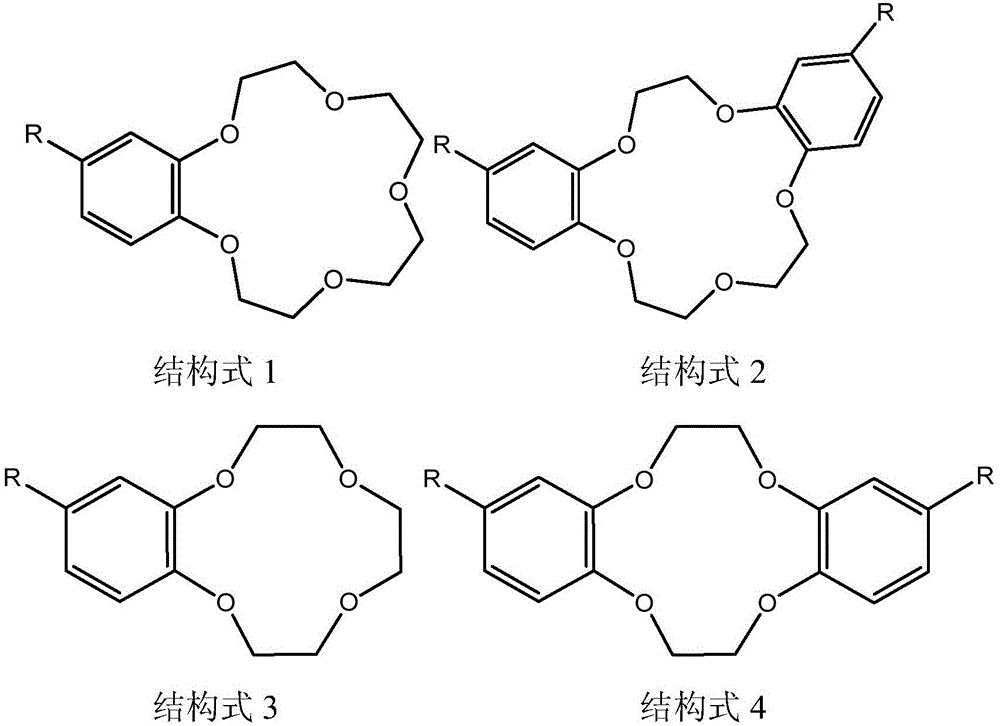

[0022] The chemical exchange method separates lithium isotopes, and the isotope exchange reaction between the two liquid phases can be expressed as:

[0023] L 7 i X + L 6 i Y ⇔ L 7 i Y + L 6 i X

[0024] Wherein, X and Y respectively represent the coordination environment of lithium ions in the two phases, as in the present invention, X represents the water phase, and Y represents the organic phase.

[0025] The single-stage extraction rate (E%) is the percentage of the lithium content entering the organic phase in one extraction process to the total amount of lithium ions in the two phases...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com