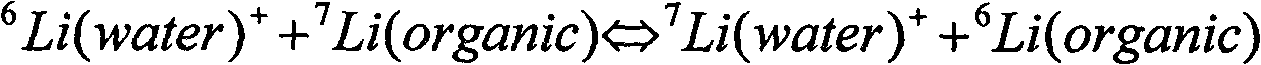

Benzo crown ether graft polymer material with lithium isotope separation effect and preparation method thereof

A technology of grafting polymer and separation effect, applied in the field of lithium isotope separation, can solve the problem of low single-stage separation factor of lithium isotope, and achieve the effects of efficient separation and continuous production, high solid loading and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

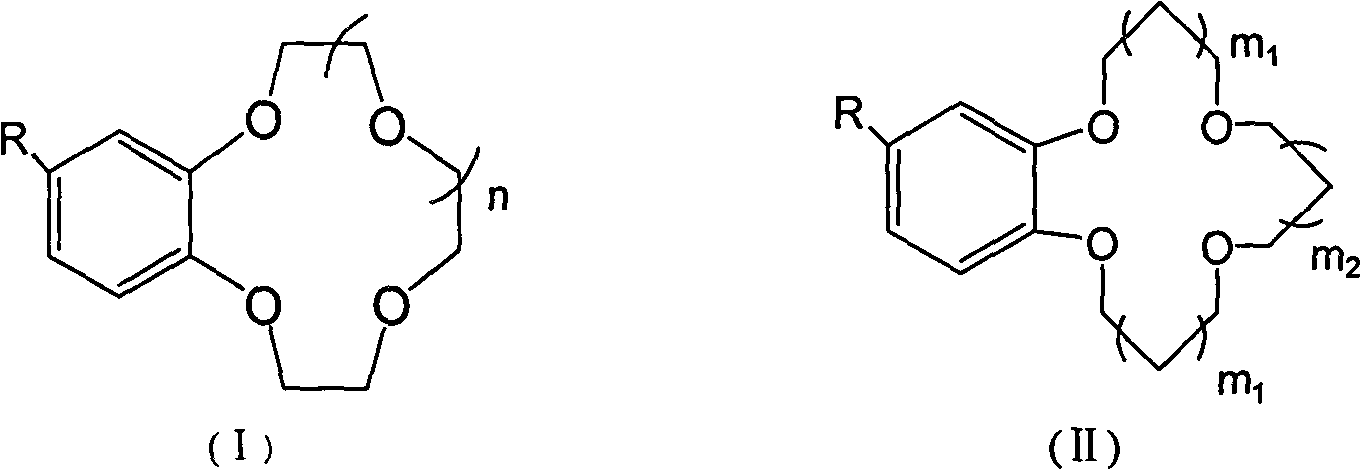

Method used

Image

Examples

Embodiment 1

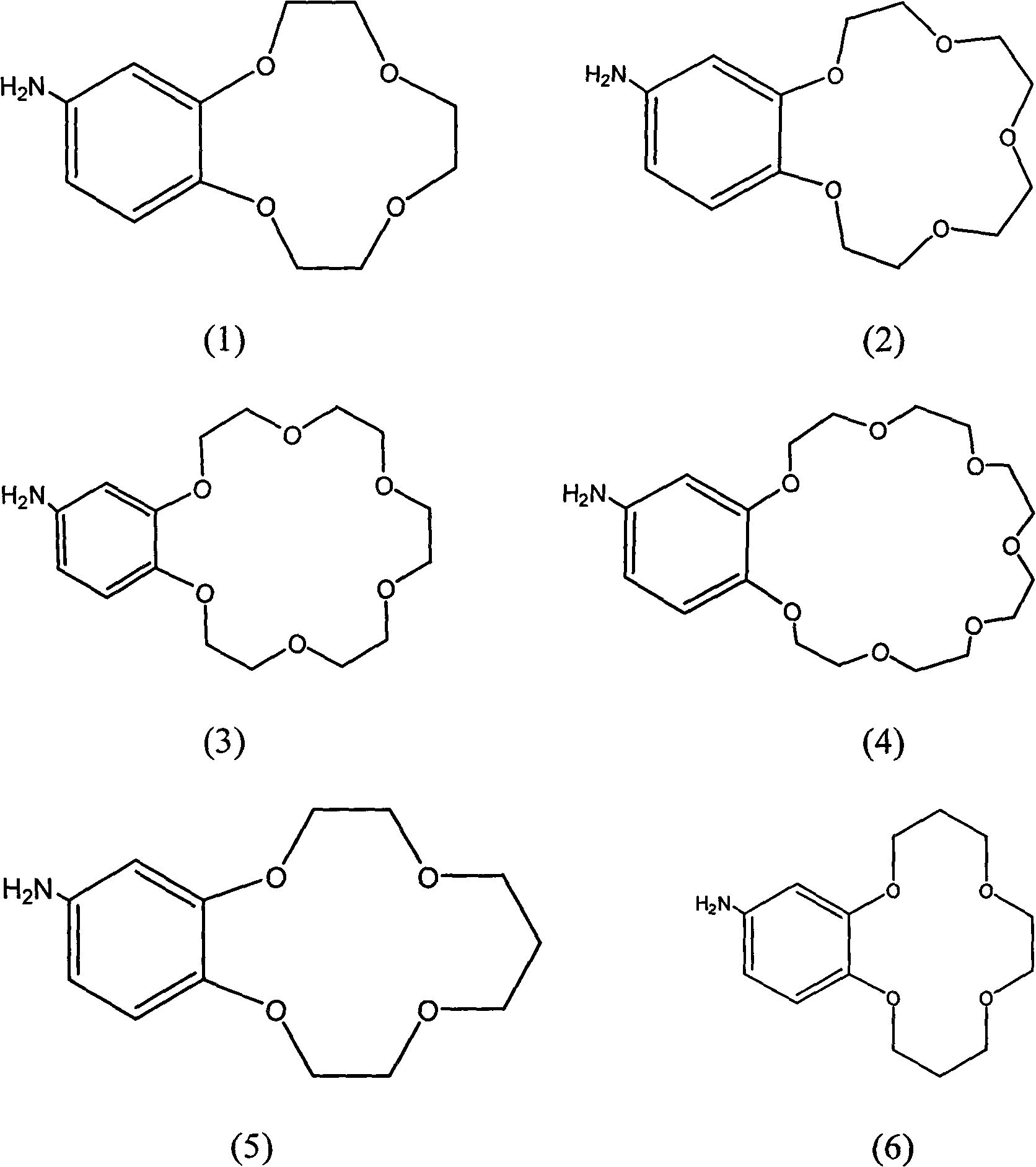

[0026] The preparation method of 4-aminobenzo 15 crown 5 grafted polysulfone polymer material is as follows: Weigh dry 2g polysulfone and place it in a four-necked flask, add dichloromethane to dissolve it completely, then add 5ml 1, 4-Dichloromethoxybutane and 0.5ml of anhydrous tin tetrachloride react at room temperature for 3 hours, then precipitate it in methanol, and dry it in a vacuum drying oven at 60°C to obtain the degree of substitution Chloromethylated polysulfone of about 1.5. Weigh 1g of chloromethylated polysulfone and dissolve it in 100mL of DMF, add 0.2g of 4-aminobenzo15crown 5 and 0.010g of anhydrous potassium carbonate and mix evenly, control the temperature at 48±2°C for 5h, pour the reaction system into Precipitate in methanol, suction filter to obtain the precipitate, wash several times with methanol and then dry to obtain a crown ether grafted polysulfone polymer material with a crown ether immobilization capacity of 0.1 mmol / g. The single-stage separat...

Embodiment 2

[0029] The preparation method of 4-hydroxybenzo15crown5-grafted polysulfone polymer is as follows: use the same method as above to prepare chloromethylated polysulfone with a degree of substitution of about 1.5, and then weigh 1g of chloromethylated polysulfone Dissolve polysulfone in 10mL of DMF, add 1g of 4-hydroxybenzo-15crown 5 and 0.488g of anhydrous potassium carbonate and mix evenly, control the temperature at 75±5°C for 24 hours, pour the reaction system into methanol to precipitate, and filter to obtain the precipitate The material was washed several times with methanol and then dried to obtain a grafted polymer material with a crown ether immobilization capacity of 2.0 mmol / g. The single-stage separation factor of the grafted polymer material for lithium isotopes obtained by liquid-solid extraction was 1.068.

Embodiment 3

[0031] The method for grafting polysulfone polymer materials with 4-aminobenzo12crown4 is as follows: the same method is used to prepare chloromethylated polysulfone with a degree of substitution of about 1.0, and accurately weigh 1g of chloromethylated polysulfone Dissolve sulfone in 20mL of DMAA, add 0.4g of 4-aminobenzo12crown 4 and 0.30g of triethylamine and mix evenly, control the temperature at 60±2°C for 12h, pour the reaction system into ethanol to precipitate, and filter to obtain the precipitate. After being washed several times with ethanol and then dried, a benzocrown ether grafted polysulfone polymer material with a crown ether immobilization amount of 1.0 mmol / g was obtained. The single-stage separation factor of polymer material to lithium isotope was 1.043 by liquid-solid extraction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com