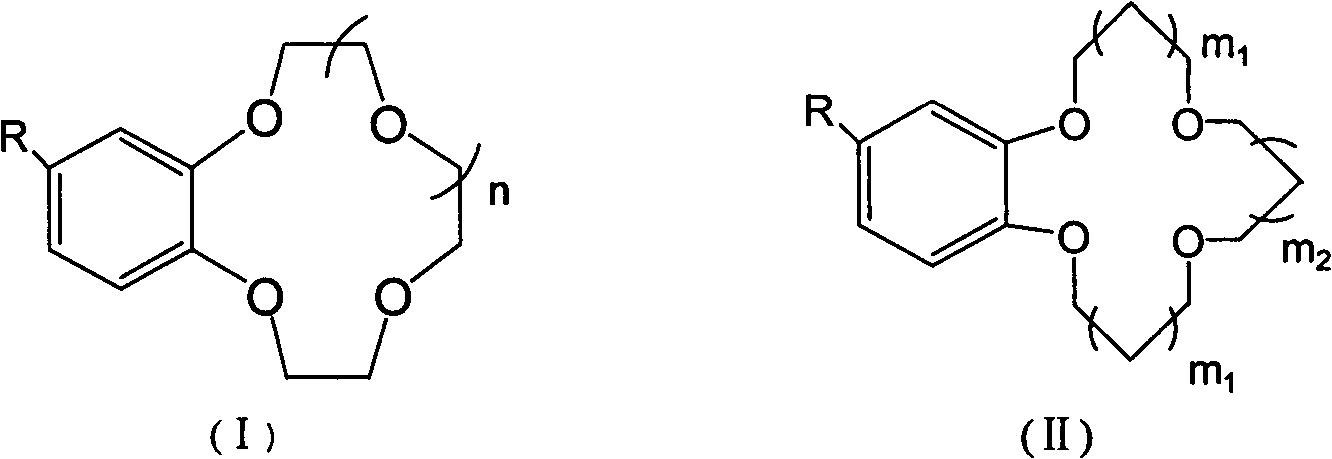

Benzocrown ether graft polymer with lithium isotopic separation effect and preparation method thereof

A graft polymer, separation effect technology, applied in the separation of different isotopic elements, separation methods, dispersed particle separation and other directions, can solve the problems of weak lithium isotope separation ability, low isotope adsorption and desorption efficiency, etc., and achieves operating conditions. Gentle, efficient separation, excellent separation factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

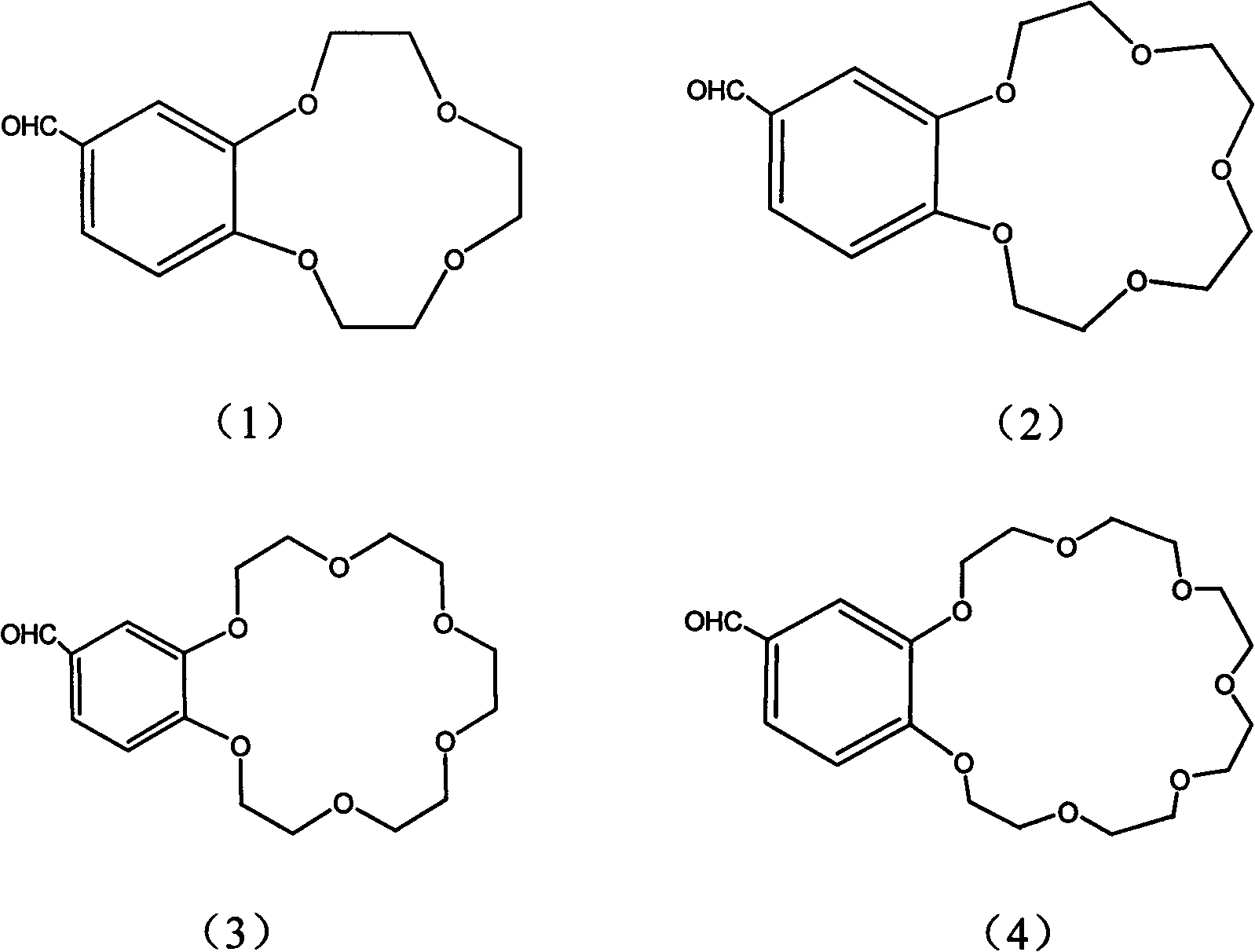

[0029] The method of grafting polyvinyl alcohol with 4-formylbenzo13crown4 is as follows: take 150mL of 6.7g / L polyvinyl alcohol aqueous solution, add 10g of 4-formyl Benzo-13-crown 4(5), add 1g of catalyst concentrated sulfuric acid according to the mass ratio of polymer to catalyst 1:1 and mix evenly, control the temperature at 70±5°C and react for 15h, then pour the reaction system into ethanol to precipitate, and obtain by suction filtration Precipitate. After being washed several times with ethanol and then dried, a 4-formylbenzo13crown4-grafted polyvinyl alcohol polymer was obtained, with a pendant group content of 3.0 mmol / g. Putting the polymer into lithium chloride aqueous solution and obtaining the single-stage separation factor of the polymer was 1.043 by means of solid-liquid extraction. Obtain polymer structure by embodiment 1 as follows:

[0030]

Embodiment 2

[0032] The method for grafting polyvinyl alcohol with 4-formylbenzo15crown5 is as follows: take 60mL of 85g / L polyvinyl alcohol aqueous solution, and drop 1g of 4-formylbenzene according to the mass ratio of polymer to benzocrown ether at 5:1 And 15 crown 5 (2), according to the mass ratio of polymer to catalyst 0.5:1, put 10g of catalyst concentrated hydrochloric acid and mix evenly, control the temperature at 80±5°C and react for 1h, then pour the reaction system into ethanol to precipitate. The precipitate was obtained by suction filtration. After being washed several times with ethanol and then dried, a crown ether grafted polymer material was obtained, with a pendant group content of 1.1 mmol / g. The polymer material was put into lithium chloride aqueous solution to obtain a single-stage separation factor of 1.033 for the polymer material by means of solid-liquid extraction.

Embodiment 3

[0034] The method for grafting polyvinyl alcohol with 4-formyl benzo 12 crown 4 is as follows: take 160 mL of 31.3 g / L polyvinyl alcohol aqueous solution, and add 1 g of 4-formyl For benzo12crown 4(1), 0.1 g of concentrated sulfuric acid was added and mixed uniformly according to the mass ratio of polymer to catalyst of 50:1, and the temperature was controlled at 80±5°C for 24 hours, and the reaction system was poured into n-butanol to precipitate. The precipitate was obtained by suction filtration, washed several times with acetone and then dried to obtain a crown ether graft polymer with a pendant group content of 0.7 mmol / g. Putting the crown ether graft polymer into the lithium chloride aqueous solution and obtaining the single-stage separation factor of the crown ether graft polymer by solid-liquid extraction was 1.043.

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com