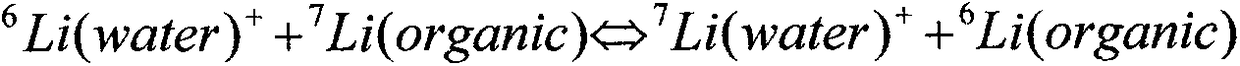

Monoazabenzo crown ether graft polymer material with lithium isotope separation effect and preparation method thereof

A graft polymer, separation effect technology, applied in the separation of different isotopic elements, separation methods, dispersed particle separation and other directions, can solve the problems of difficult lithium isotope, low single-stage separation factor of lithium isotope, etc. Mild operating conditions and high solid loading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

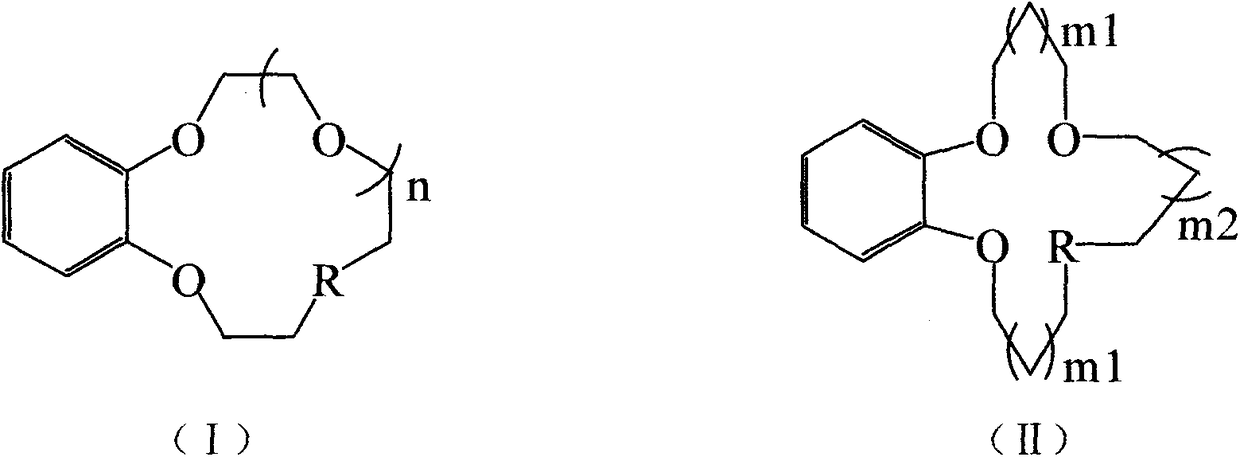

Method used

Image

Examples

Embodiment 1

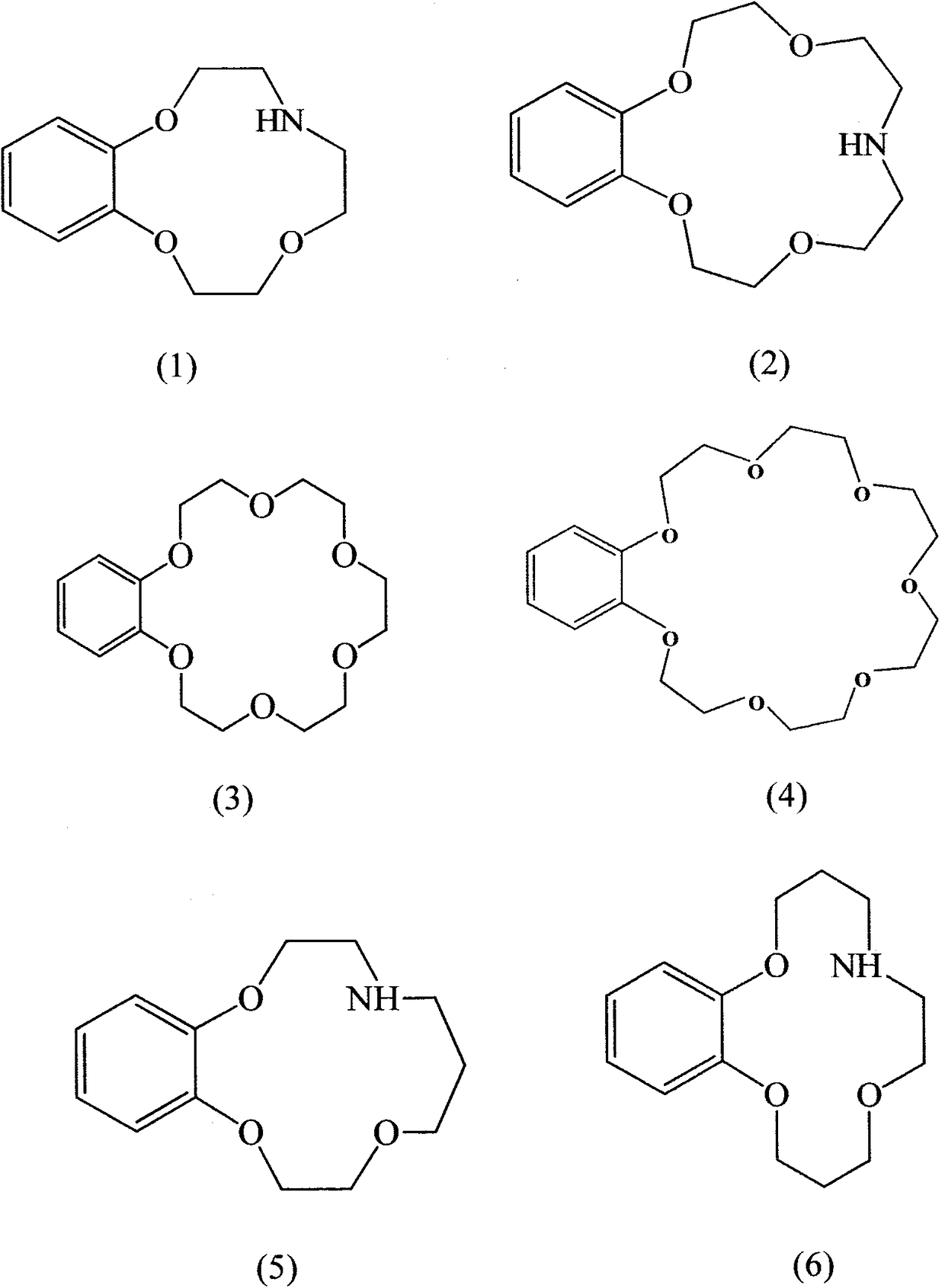

[0022]The preparation method of benzomonaazepine-15-crown-5 grafted polysulfone polymer material is as follows: Weigh dry 18g polysulfone and place it in a three-necked flask, add chloroform to dissolve it completely, cool to 10 Below ℃, then add 63ml of trimethylchlorosilane, 15g of paraformaldehyde and 0.6ml of tin tetrachloride, stabilize for 15 minutes and react at 50℃ for 11 hours, then precipitate it in methanol, Dry in a vacuum drying oven to obtain chloromethylated polysulfone with a substitution degree of about 0.4. Weigh 1.5 g of chloromethylated polysulfone and dissolve it in 12 mL of DMF, add 0.86 g of benzodiazepine-15-crown-5, control the temperature at 60±5°C for 6 hours, pour the reaction system into ethanol for precipitation, pump The precipitate was obtained by filtration, washed several times with ethanol and then dried to obtain a crown ether grafted polysulfone polymer material with a crown ether immobilization capacity of 0.58 mmol / g. The single-stage se...

Embodiment 2

[0025] The preparation method of 4-hydroxybenzo15crown5-grafted polysulfone polymer is as follows: use the same method as above to prepare chloromethylated polysulfone with a degree of substitution of about 1.5, and then weigh 1g of chloromethylated polysulfone Dissolve the polysulfone in 10mL DMF, add 1g of 4-hydroxybenzo15crown 5 and 0.488g of anhydrous potassium carbonate and mix evenly, control the temperature at 80±5°C for 24h, pour the reaction system into methanol to precipitate, and filter with suction to obtain The precipitate was washed several times with methanol and then dried to obtain a grafted polymer material with a crown ether immobilization capacity of 2.0 mmol / g. The single-stage separation factor of the grafted polymer material for lithium isotopes obtained by liquid-solid extraction was 1.068.

Embodiment 3

[0027] The method for grafting polysulfone polymer materials with 4-aminobenzo12crown4 is as follows: the same method is used to prepare chloromethylated polysulfone with a degree of substitution of about 1.0, and accurately weigh 1g of chloromethylated polysulfone Dissolve sulfone in 20mL of DMAA, add 0.4g of 4-aminobenzo12crown 4 and 0.30g of triethylamine and mix evenly, control the temperature at 60±5°C for 12h, pour the reaction system into ethanol to precipitate, and filter to obtain the precipitate. After being washed several times with ethanol and then dried, a benzocrown ether grafted polysulfone polymer material with a crown ether immobilization amount of 1.0 mmol / g was obtained. The single-stage separation factor of polymer material to lithium isotope was 1.043 by liquid-solid extraction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com