Method for preparing functional polymer micro-porous membrane with reaction-solution phase inversion control method

A solution phase inversion, functional polymer technology, which is applied in the field of the preparation of crown ether grafted polymer microporous membranes by the reaction-controlled immersion precipitation phase inversion method, can solve the problems of poor controllability of membrane structure, insoluble and infusible polymers, etc. Chemical modification resistance and other problems, to achieve the effect of improved fracture strength, mild operating conditions and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

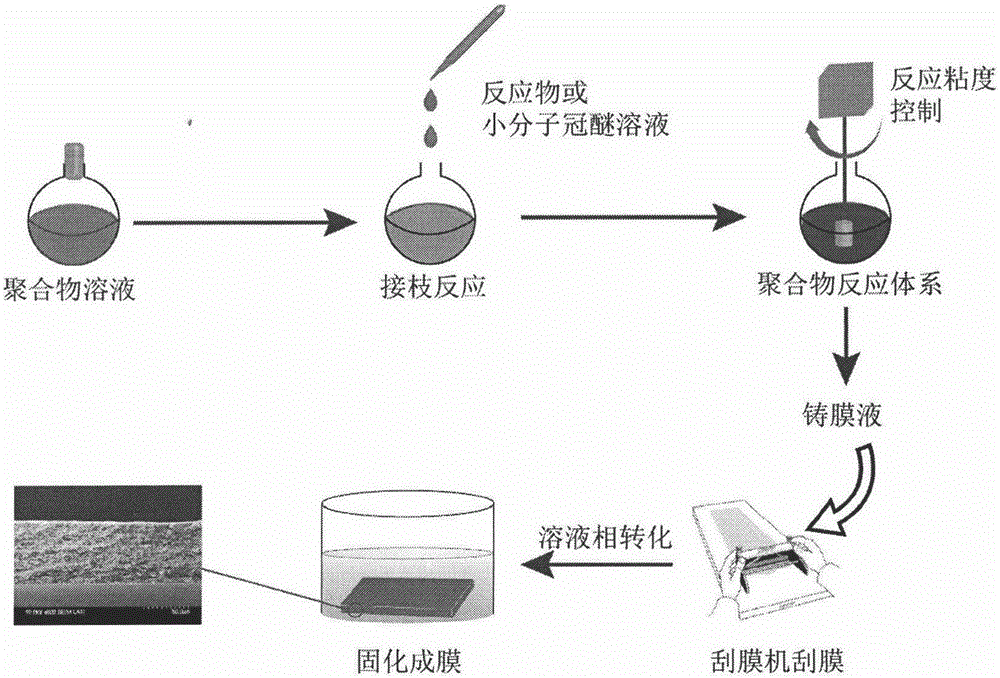

Method used

Image

Examples

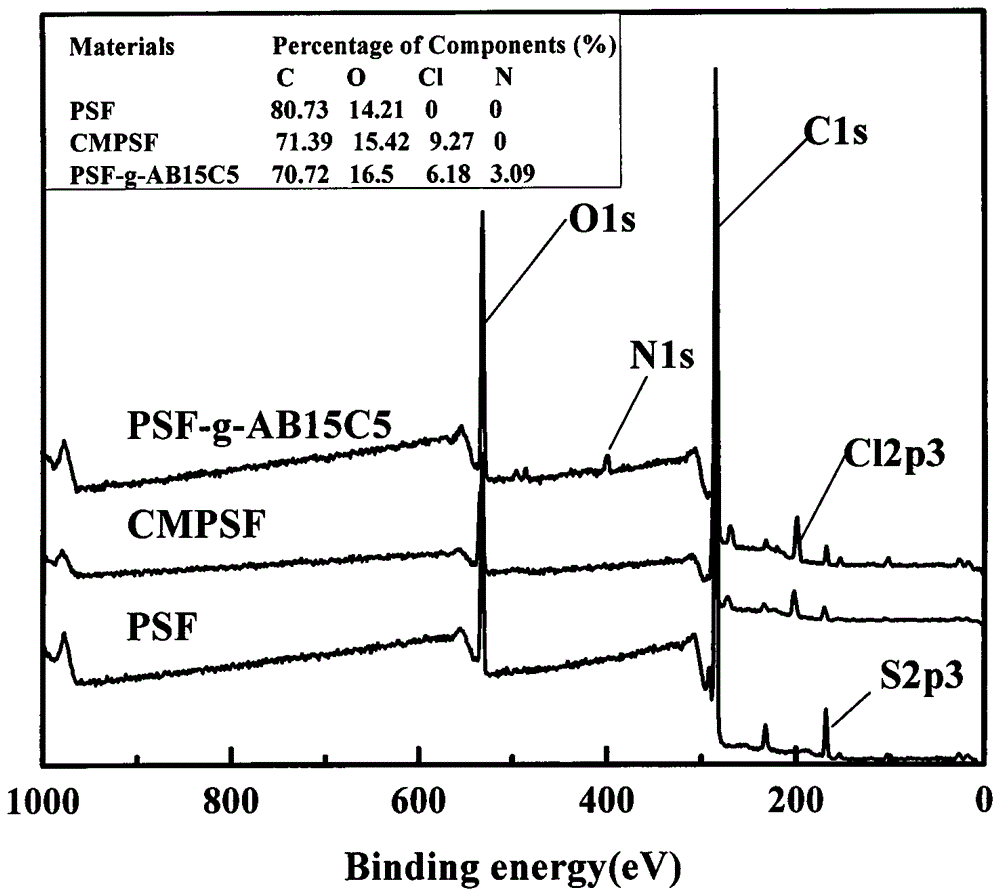

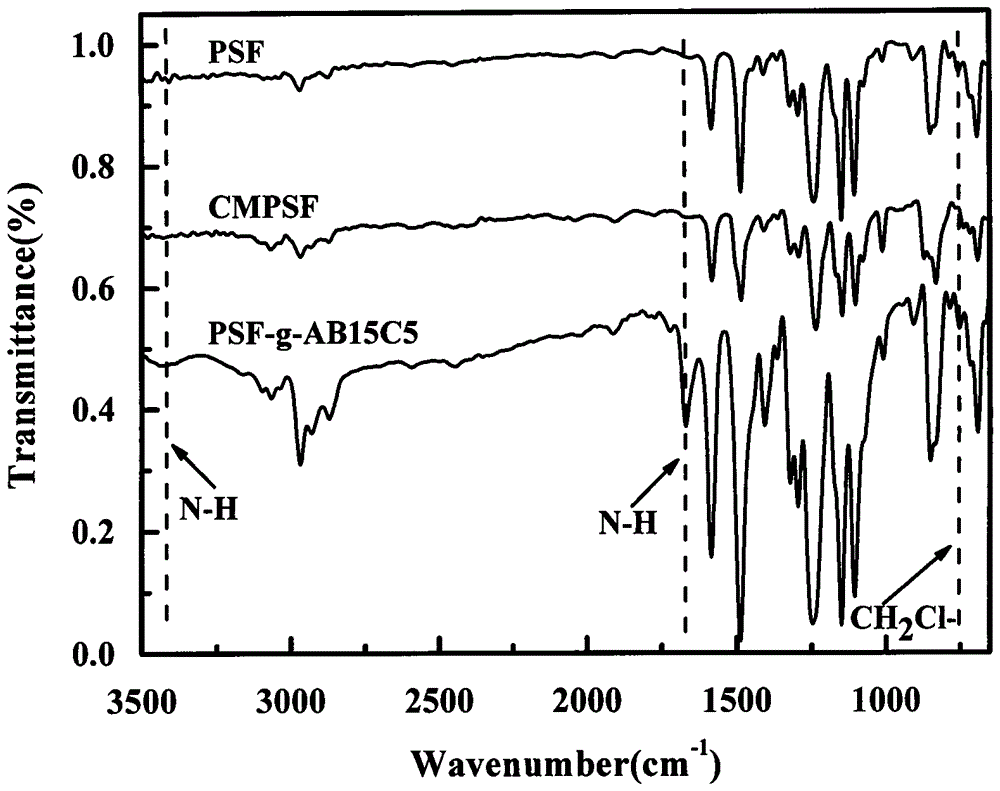

Embodiment 1

[0026] Reaction-controlled phase inversion method to prepare 4-aminobenzo-15-crown 5 grafted polysulfone microporous membrane, specifically as follows: Weigh 3g chloromethylated polysulfone (chloromethyl substitution degree is 20%) and dissolve in 57mlDMF After completely dissolving, add 1.9g of 4-aminobenzo-15-crown-5 ether to it, react at 45°C for 22 hours, then vacuum defoam at 20°C, then apply the casting solution on a glass plate, place the glass plate on In coagulation bath water (20° C.), take out and dry after coagulation and molding for 30 minutes, and prepare 4-aminobenzo-15-crown 5 grafted polysulfone polymer microporous membrane. The polymer microporous membrane prepared under the above conditions was circulated and adsorbed 100mL0.5mol / L lithium iodide solution under 0.05MPa pressure at 20°C for 30 minutes to obtain 4-aminobenzo-15-crown 5-grafted polysulfone polymer microporous membrane. The pore membrane separation factor was 1.035.

Embodiment 2

[0028]Reaction-controlled phase inversion method to prepare 4-aminobenzo-15-crown 5 grafted polyethersulfone microporous membrane, specifically as follows: Weigh 3g of chloromethylated polyethersulfone (chloromethyl substitution degree is 50%) and dissolve After completely dissolving in 57ml of DMF, add 1.9g of 4-aminobenzo-15-crown-5 ether to it, react at 45°C for 15h, then vacuum degassing at 20°C, and then apply the casting solution on a glass plate. The plate was placed in coagulation bath water (20° C.), and after solidification and molding for 30 minutes, it was taken out and dried to prepare a 4-aminobenzo-15-crown 5 grafted polyethersulfone polymer microporous membrane. The polymer microporous membrane prepared under the above conditions was circulated and adsorbed 100mL0.5mol / L lithium iodide solution under 0.05MPa pressure at 20°C for 30 minutes to obtain 4-aminobenzo-15-crown 5-grafted polyethersulfone polymer The microporous membrane separation factor was 1.040.

Embodiment 3

[0030] Reaction-controlled phase inversion method to prepare 4-aminobenzo-12-crown 4 grafted polysulfone microporous membrane, specifically as follows: Weigh 3g chloromethylated polysulfone (chloromethyl substitution degree is 20%) and dissolve in 57mlDMF After completely dissolving, add 1.7g of 4-aminobenzo-15-crown-5 ether to it, react at 45°C for 22 hours, then vacuum defoam at 20°C, then apply the casting solution on a glass plate, place the glass plate on In coagulation bath water (20° C.), take out and dry after coagulation and molding for 30 minutes, and prepare 4-aminobenzo-15-crown 5 grafted polysulfone polymer microporous membrane. The polymer microporous membrane prepared under the above conditions was circulated and adsorbed 100mL0.5mol / L lithium iodide solution under 0.05MPa pressure at 20°C for 30 minutes to obtain 4-aminobenzo-12-crown-4 grafted polysulfone polymer microporous membrane. The pore membrane separation factor was 1.035.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com