Magnetic particle extractive agent and method for isolating radionuclide

A technology of radionuclide and magnetic particles, which is applied in the field of radioactive waste liquid treatment, can solve problems such as affecting application, instability, and difficult desorption, and achieve continuous large-scale separation, easy desorption, and high selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1, Magnetic Fe 3 o 4 Gel preparation

[0039] Weigh 8.6 g FeCl 2 and 23.6 g FeCl 3 , dissolved in 500ml of water, heated to 80°C, passed nitrogen into the container, poured 25ml of 25% ammonia water into the aqueous solution, and immediately started dripping oleic acid at a rate of 0.5ml / min until the aqueous solution became clear. Continue to keep the temperature for 1 hour, separate it with a magnet, and wash it repeatedly with deionized water to obtain a black agglomerate magnetic Fe 3 o 4 gel. The transmission electron microscope test showed that the average size of the particles was 8 nanometers.

Embodiment 2

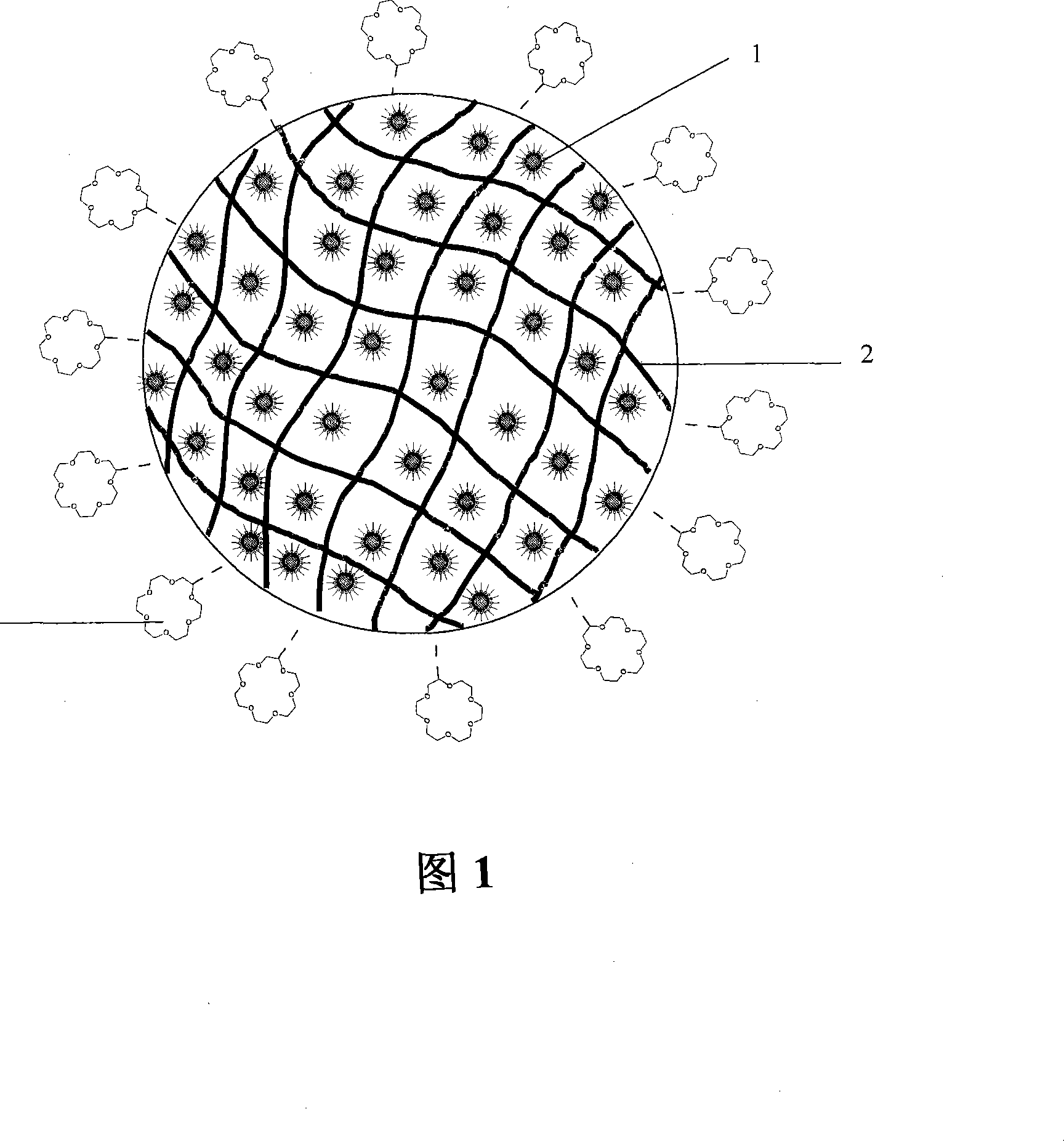

[0040] Embodiment 2, the preparation of magnetic polymer particles

[0041] Get 20 grams of magnetic Fe prepared by embodiment 1 3 o 4 For the gel, add 150ml of methyl acrylate and 10ml of divinylbenzene crosslinking agent to the organic phase, stir to form an oil phase magnetic colloid; add 10 grams of polyvinyl alcohol emulsifier to 500ml of deionized water, and stir at 50°C Prepare the water phase in 60 minutes; mix the water phase and the oil phase to obtain an oil-in-water emulsion system, add 4 grams of oil-soluble initiator benzoyl peroxide, and stir at 80 ° C for 6 hours to carry out polymerization reaction to obtain magnetic polymethyl acrylate Ester pellets. The magnetic nano-Fe in the magnetic polymethyl acrylate particles 3 o 4 Granules make up about 10%.

[0042] It should be noted that the preparation of crosslinked polymers is not limited to the crosslinking of methyl acrylate and divinylbenzene, but other acrylic esters and vinylbenzene polymers can be sel...

Embodiment 3

[0044] Embodiment 3, the immobilization and radionuclide of magnetic particle extractant (nanometer magnetic microsphere-polymer-dibenzo-18-crown 6) 90 Separation of Sr

[0045] (1) Immobilization of crown ethers on the surface of magnetic particles

[0046] Mix 5 grams of magnetic polymethyl acrylate particles prepared in Example 2 with 150 ml of ethylenediamine, and stir and react at a constant temperature of 50°C for 0.5 hours. During this process, amine groups are formed on the surface of the magnetic polymethyl acrylate particles; Dialdehyde, stirred and reacted at 50°C for about 4 hours, during which the amine groups on the surface of the magnetic polymethyl acrylate particles were converted into aldehyde groups; finally, 1 gram of 4-aminodibenzo-18-crown 6 was added, and stirred at 50°C for about 4 hours. After 4 hours, the magnetic particle extractant containing dibenzo-18-crown 6 on the surface was obtained, wherein the crown ether concentration was 0.5 mmol / g. Acco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com