Polymer/graphene hybridization nanofiltration composite membrane and preparation method thereof

A graphene and composite membrane technology, applied in the field of membrane separation, can solve the problems of low permeability and low permeability selectivity, and achieve the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Preparation of aqueous medium: dissolve and disperse piperazine and graphene oxide in ultrapure water, and disperse them evenly by ultrasonication for 15 minutes. / L of aqueous medium.

[0032] (2) Preparation of oil phase medium: dissolve trimesoyl chloride in n-heptane, and prepare the mass fraction of trimesoyl chloride to be 7.5×10 -4 mol / L oil phase medium.

[0033] (3) Immerse the wet polysulfone porous support membrane into the water phase medium, take it out after immersion for 10 minutes, roll the surface of the support membrane with a rubber roller, remove the excess aqueous solution on the surface of the polysulfone porous support membrane, and then the polysulfone porous support membrane The surface of the support membrane is in contact with the oil phase medium on one side to carry out a polymerization reaction for 40 seconds to obtain a nascent hybrid nanofiltration composite membrane.

[0034] (4) The nascent hybrid nanofiltration composite membran...

Embodiment 2-4

[0037] Except that the concentration of graphene oxide in the aqueous medium is adjusted, all the others are the same as in Example 1.

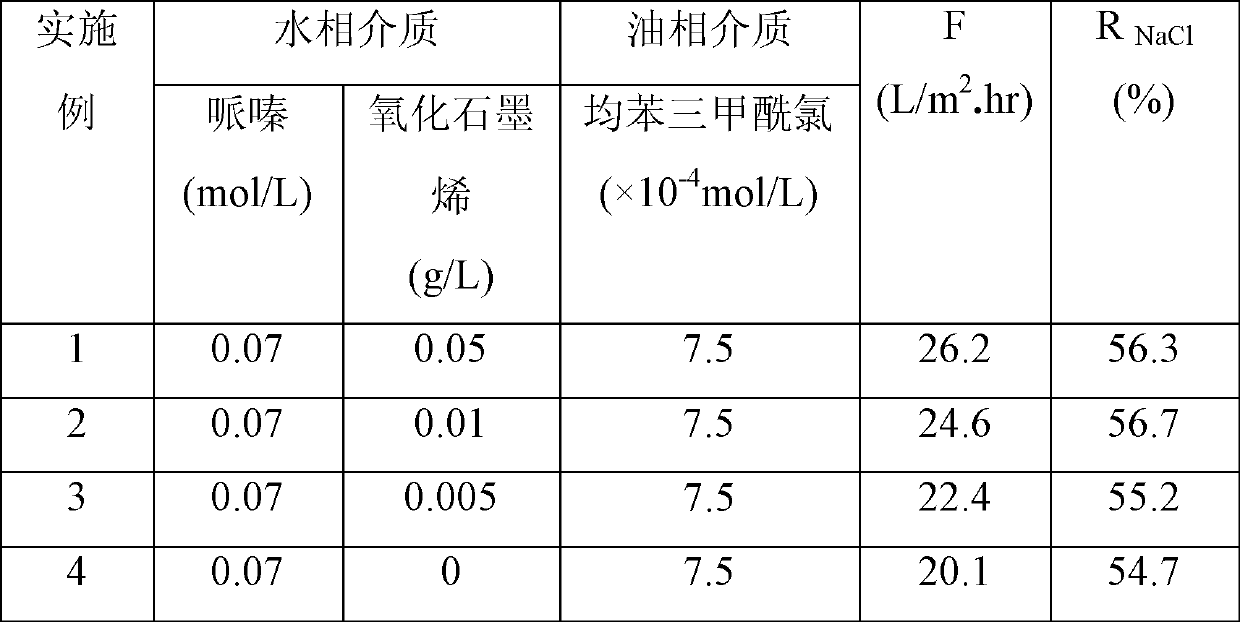

[0038] The polymer / graphene hybrid nanofiltration composite membrane prepared in Examples 2-4 was tested for water flux and NaCl rejection, and the results are shown in Table 1.

[0039] Table 1

[0040]

[0041] Examples 1-4 are to investigate the influence of graphene oxide concentration in the aqueous medium on the water flux and NaCl rejection rate of the prepared polymer / graphene hybrid nanofiltration composite membrane.

Embodiment 5-7

[0043] Example 5 is the same as Example 1 except that aminated graphene is used in the aqueous medium.

[0044] Embodiments 6-7 are the same as Embodiment 5 except that the concentration of aminated graphene in the aqueous medium is adjusted.

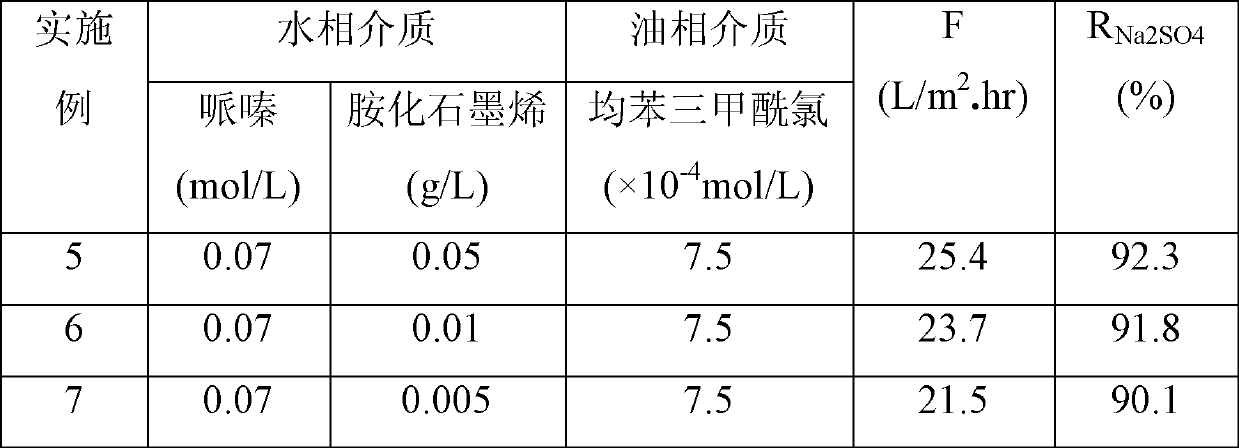

[0045] The polymer / graphene hybrid nanofiltration composite membrane that embodiment 5-7 makes is carried out water flux and Na 2 SO 4 The retention rate test, the results are shown in Table 2.

[0046] Table 2

[0047]

[0048] Embodiment 5-7 is to investigate the polymer / graphene hybrid nanofiltration composite film water flux and Na 2 SO 4 Influence on retention rate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com