PMP copolymer and preparation method thereof

A copolymer and polyethylene technology, applied in the field of PMP copolymer and its preparation, can solve the problems of unfavorable processing and application, high melting temperature, high brittleness, etc., and achieve controllable molecular weight and molecular weight distribution, high melt strength, The effect of good processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

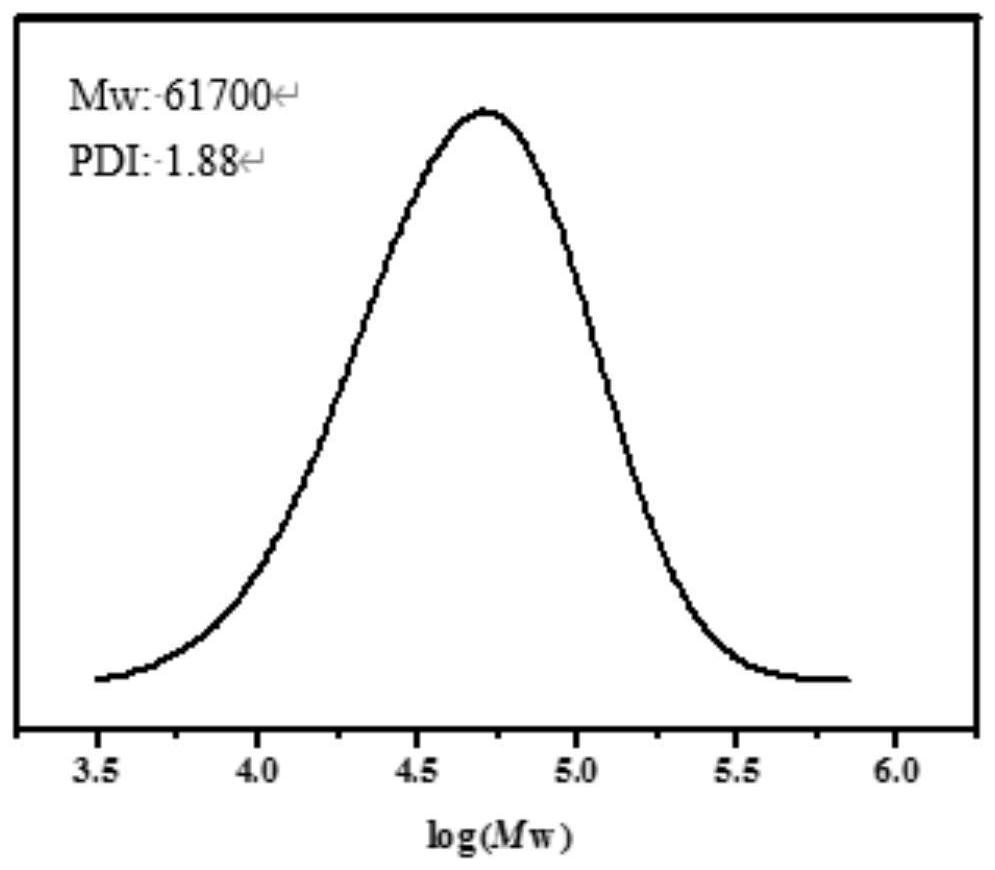

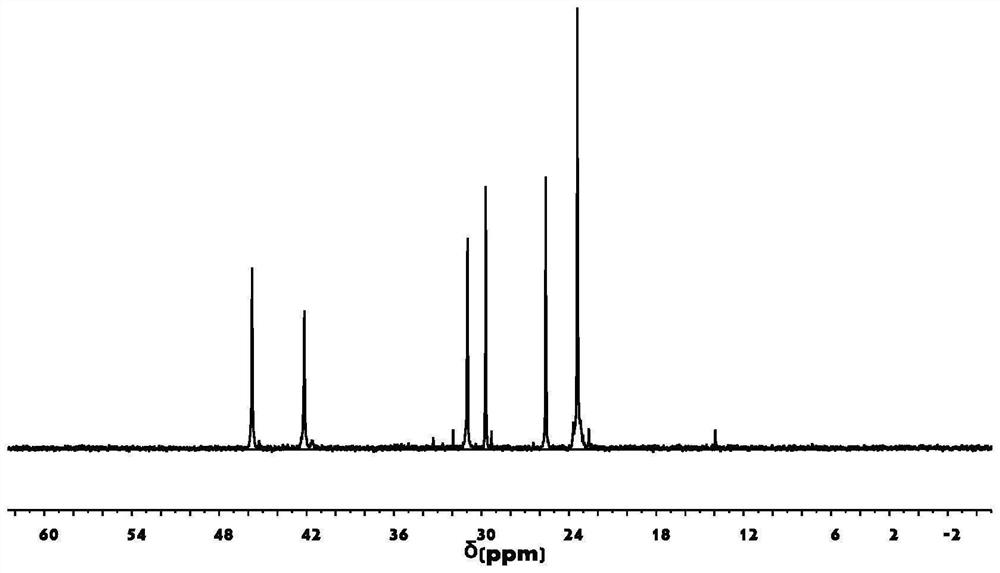

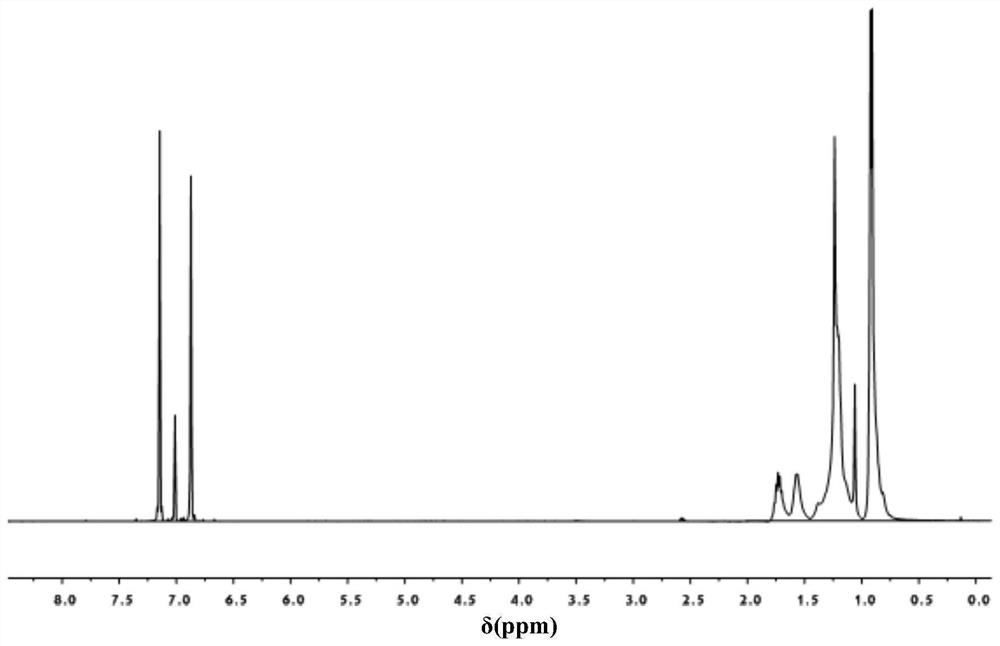

Embodiment 1

[0046] Under anhydrous and oxygen-free conditions, toluene is used as a solvent, the temperature in the reactor is controlled to 50°C, and the pressure is 0.1MPa. Ethylene gas is passed into the reactor, and triisobutylaluminum, methylalumoxane, and Catalyst A is reacted, and the reaction time is 5 minutes to obtain long-chain polyethylene; stop feeding ethylene gas, and continue the reaction for 5 minutes, so that the ethylene in the reactor is completely consumed, and PMP monomer is added to make the monomer concentration in the reactor 1M / L, sequentially add tetrakis(pentafluorophenyl) triphenylcarbenium borate, catalyst B to carry out copolymerization reaction between long-chain polyethylene and PMP, the reaction temperature is 70°C, the polymerization time is 90min, and the mixed solution obtained after the termination reaction is carried out in Precipitate in ethanol to obtain the polymer, filter it with a Buchner funnel, and dry the polymer in a vacuum oven at 40°C to obt...

Embodiment 2

[0056] Under anhydrous and oxygen-free conditions, use toluene as a solvent, control the temperature in the reactor to 70°C, and the pressure to 0.1MPa, pass ethylene gas into the reactor, and add diethylzinc, methylaluminoxane, and catalyst in sequence A reacts, and the reaction time is 10min, obtains long-chain polyethylene;

[0057] Stop feeding ethylene gas, continue to react for 5 minutes, so that the ethylene in the reactor is completely consumed, add PMP monomer, make the monomer concentration in the reactor 2M / L, add tris(pentafluorophenyl)borane, catalyst B in sequence , Copolymerize long-chain polyethylene and PMP, the reaction temperature is 70°C, the polymerization time is 90min, the mixed solution obtained after the termination of the reaction is precipitated in ethanol to obtain a polymer, filtered with a Buchner funnel, and dried in a vacuum oven at 40°C for polymerization Thing, obtains the PMP copolymer with polyethylene side chain, structural formula is as fo...

Embodiment 3

[0066] Under anhydrous and oxygen-free conditions, use toluene as a solvent, control the temperature in the reactor to 80°C, and the pressure to 0.1MPa, pass ethylene gas into the reactor, and add trimethylaluminum, methylalumoxane, and catalyst in sequence A reacts, and the reaction time is 30min, obtains long-chain polyethylene;

[0067] Stop feeding ethylene gas, continue to react for 10 minutes, so that the ethylene in the reactor is completely consumed, add PMP monomer, make the monomer concentration in the reactor 1M / L, add tri-n-butylammonium tetraphenylborate, catalyst B in sequence , Copolymerize long-chain polyethylene and PMP, the reaction temperature is 70°C, the polymerization time is 90min, the mixed solution obtained after the termination of the reaction is precipitated in ethanol to obtain a polymer, filtered with a Buchner funnel, and dried in a vacuum oven at 40°C for polymerization Thing, obtains the PMP copolymer with polyethylene side chain, structural for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com