Polyesteramide hot melt adhesive with low melting point and preparation method thereof

A polyester amide, low melting point technology, used in adhesives, fiber types, textiles and papermaking, etc., can solve the problem of polyester hot melt adhesive performance not reaching a satisfactory level, and achieve fast curing and good thermal stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] In a four-necked flask of a 2.0L distillation unit equipped with a thermometer, a mechanical stirrer, and a reflux condenser, add terephthalic acid (2.0mol), propylene glycol (2.0mol), diethylene glycol (1.50mol) and tetratitanate Ethyl ester (0.0007mol), blow nitrogen, heat, start stirring, turn on the condensed water, when the temperature in the kettle reaches 145°C, the material begins to dissolve, and when the temperature continues to rise to about 180°C, methanol begins to distill, continue the reaction and keep the temperature in the kettle When the temperature reaches 180-185°C and the distilled water reaches more than 90% of the theoretical amount, the esterification reaction ends.

[0019] Add isophthalic acid (1.2mol), adipic acid (0.3mol), decanediamine (0.35mol) and caprolactam (0.35mol) in the above-mentioned product and stir to heat up, carry out esterification and amidation reaction, when still internal temperature When it reaches about 185°C, water begin...

Embodiment 2-6

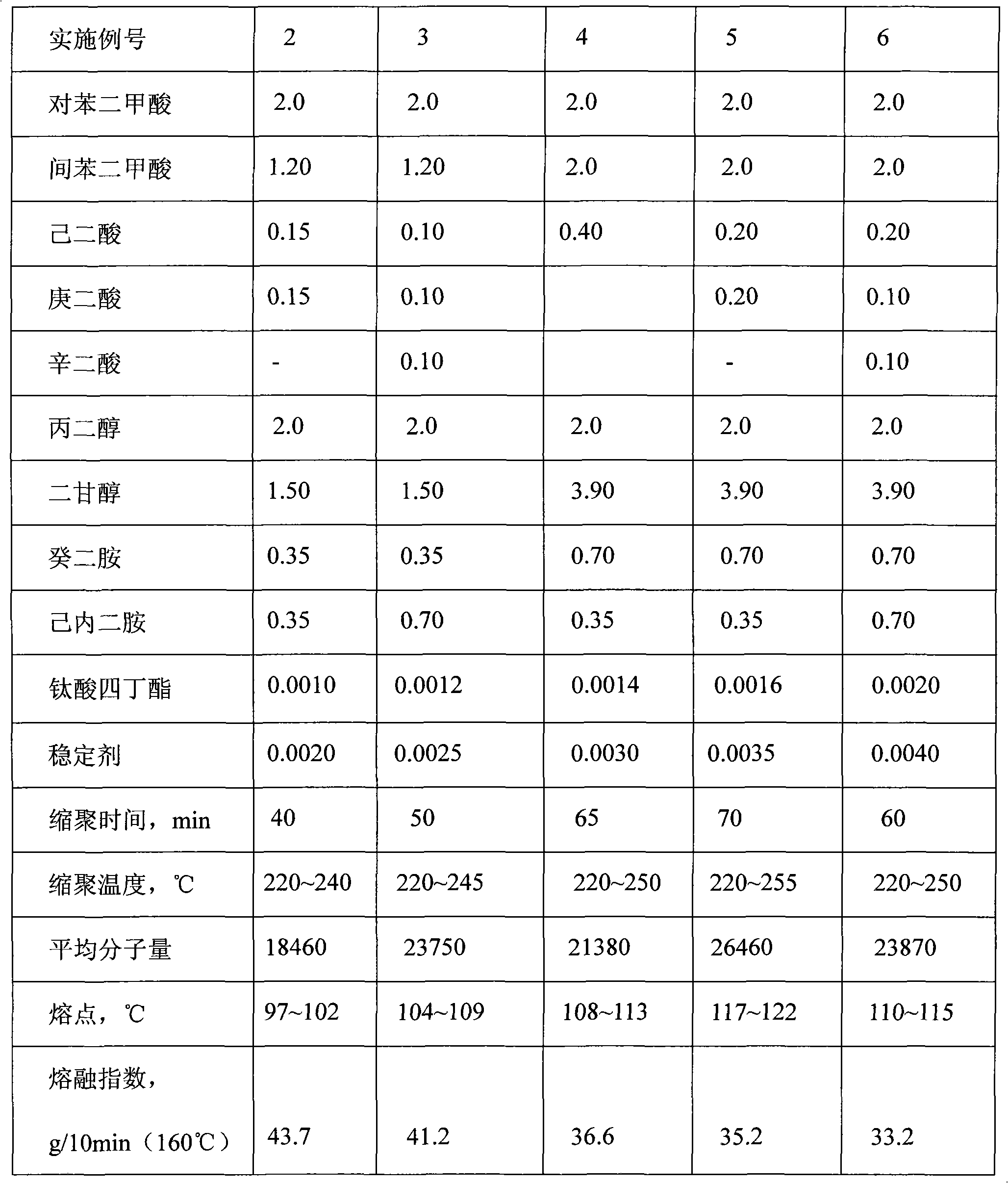

[0021] The steps and process conditions of Embodiment 2-6 are basically the same as those of Example 1. The modified process conditions and raw material molar ratio are shown in Table 1, and the properties of the resulting product are also listed in Table 1.

[0022] Relevant processing conditions and material proportioning and product performance of table 1 embodiment 2-6 (raw material proportioning is the amount of substance, mol)

[0023]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com