Composite damping material with interlayer being as metal rubber

A composite damping material and metal rubber technology, applied in the field of composite damping materials, can solve the problems of sensitive equipment pollution, poor corrosion resistance, easy aging, etc., and achieve the effect of good weight reduction, diversified application methods, and good vibration reduction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

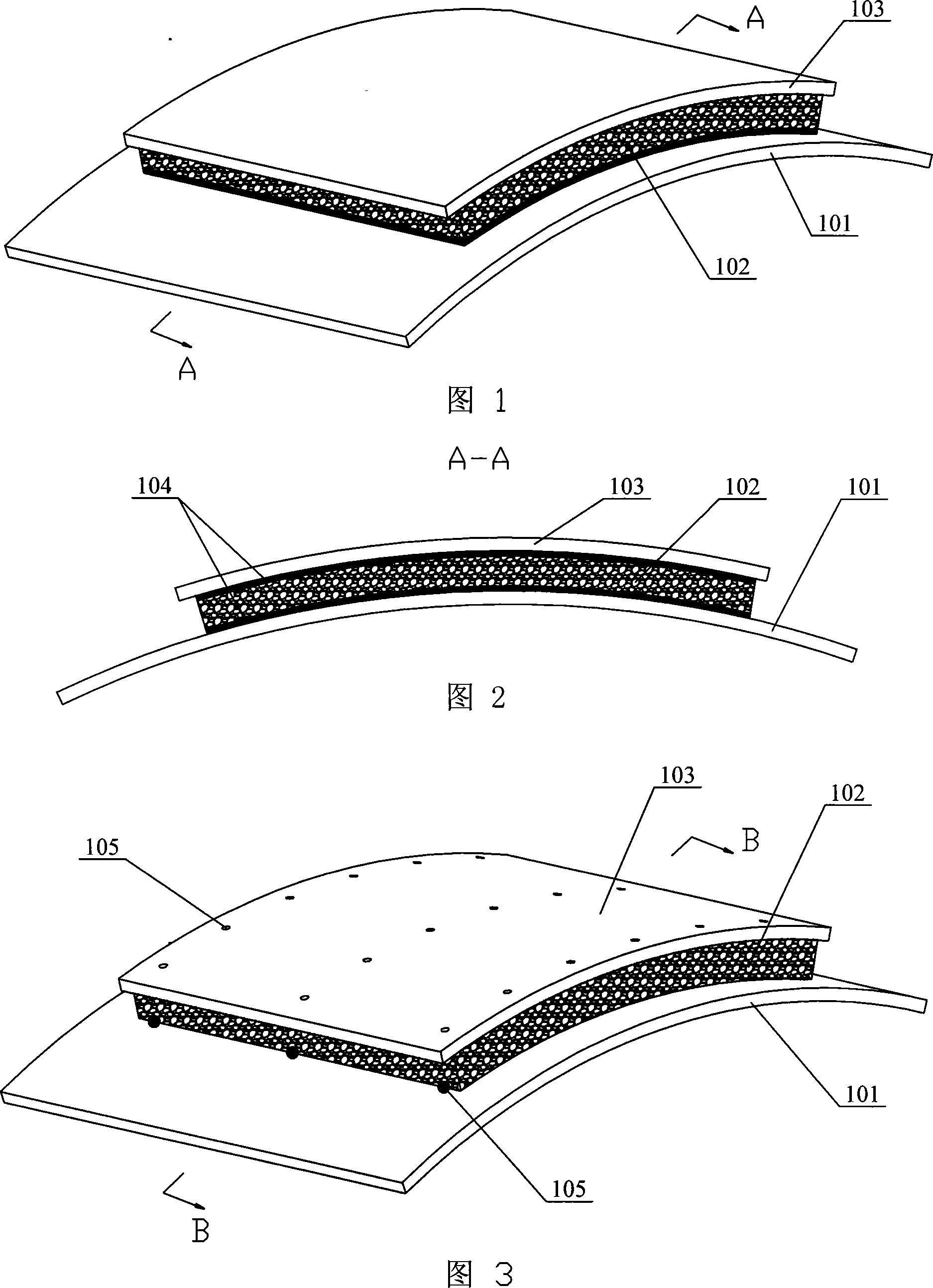

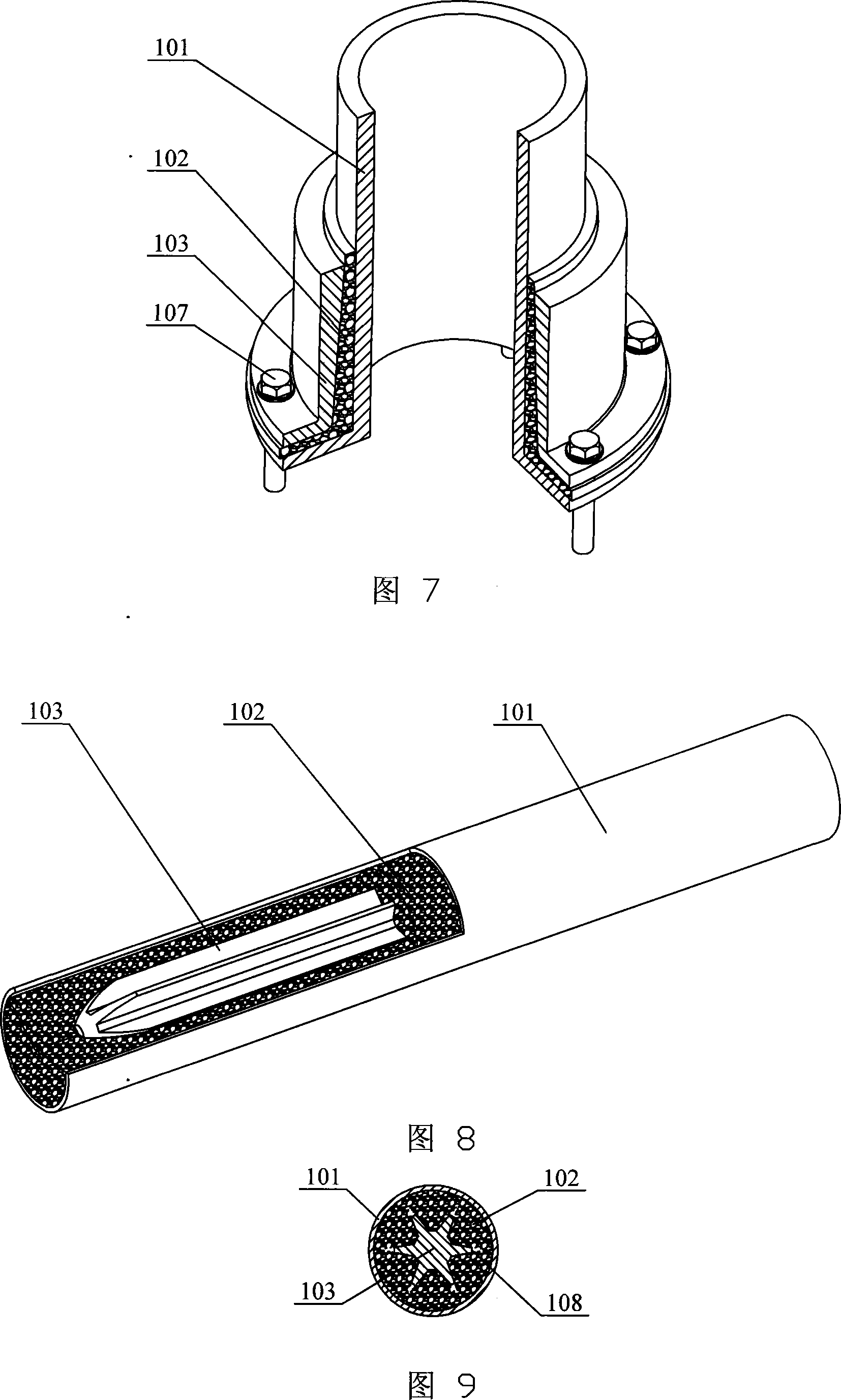

[0009] Specific Embodiment 1: This embodiment will be described with reference to FIG. 1 and FIG. 2 . This embodiment is made up of base layer 101, metal rubber layer 102 and constraint layer 103, metal rubber layer 102 is sandwiched between base layer 101 and constraint layer 103, the lower surface of metal rubber layer 102 and the upper surface of base layer 101 and metal rubber layer 102 The upper surface of the upper surface and the lower surface of the constraining layer 103 are solidified and integrated by epoxy adhesive 104 under a certain temperature and pressure to form a composite damping material with a metal rubber interlayer.

[0010] The base layer 101 is a structural shell that needs to be damped. When the structure vibrates, the metal rubber is deformed, and the metal rubber is rubbed inside to absorb and dissipate energy, so as to achieve the purpose of vibration reduction and noise reduction. Installing the constraint layer 103 outside the metal rubber dampin...

specific Embodiment approach 2

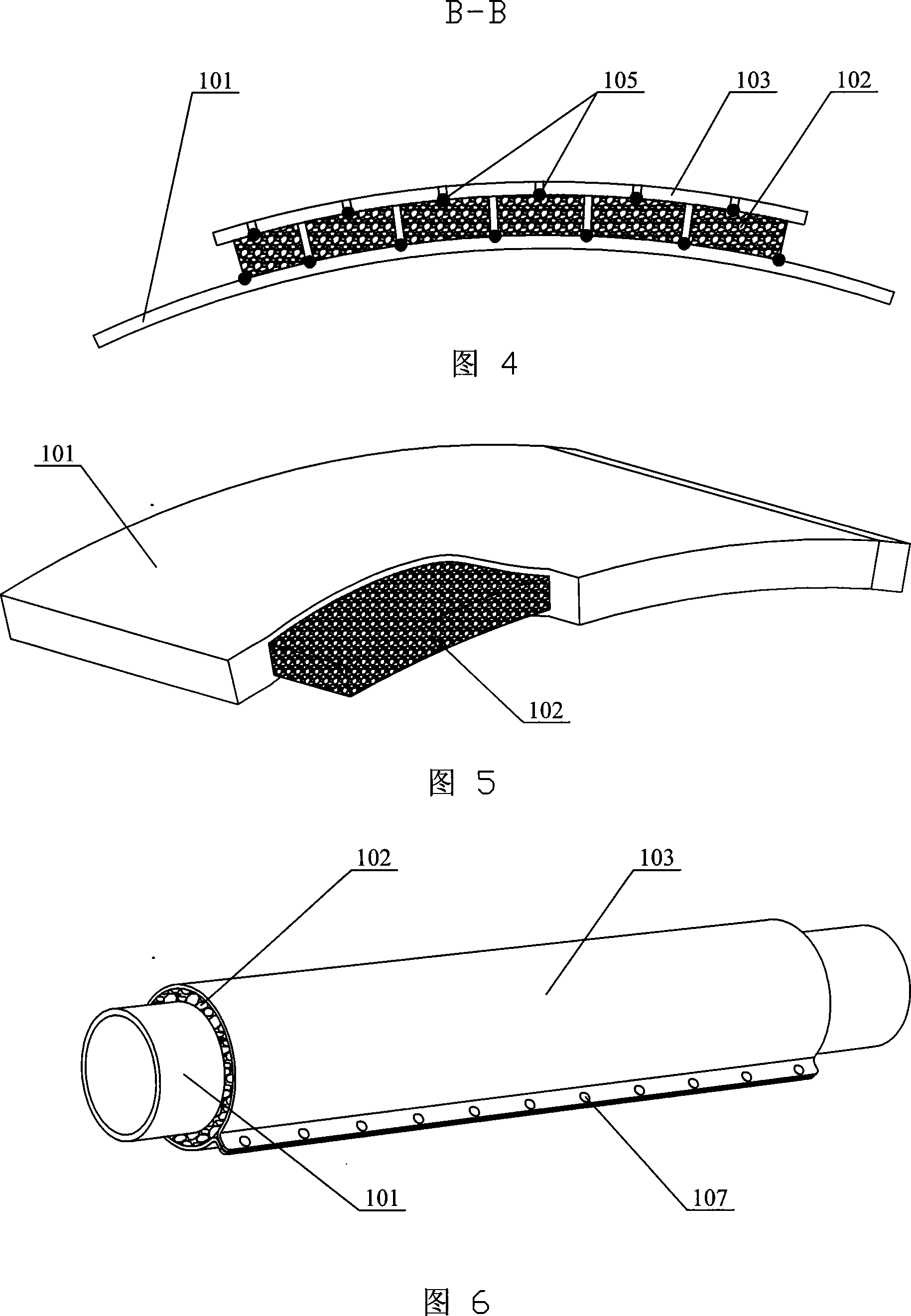

[0011] Specific Embodiment 2: This embodiment is described in conjunction with FIG. 3 . The difference between this embodiment and the first embodiment is that it also includes welding holes 106 and welding points 105, the base layer 101 and the constraining layer 103 are provided with welding holes 106, the lower surface of the metal rubber layer 102 and the upper surface of the base layer 101 The upper surface of the metal rubber layer 102 and the lower surface of the constraining layer 103 are welded together by several welding spots 105 . Others are the same as in the first embodiment. In this embodiment, the welding method is adopted, which is suitable for harsh working environments such as high and low temperature and vacuum.

specific Embodiment approach 3

[0012] Specific Embodiment Three: This embodiment will be described in conjunction with FIG. 5 . The difference between this embodiment and the first embodiment is that the substrate 101 is a hollow plate with an opening on one side, and the metal rubber layer 102 is made into a flat plate, filled in the hollow plate 101, and then the opening is closed to form a sandwich It is a composite damping plate made of metal rubber. When the plate vibrates, it drives the metal rubber damping layer 102 to deform and consume energy. The whole structure can be used as a structural member with vibration damping function. Metal-rubber filler plates are suitable as a support structure with vibration-damping capabilities, and as a clamping structure that can provide elasticity and damping.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com