Hydrogen-based silicone resin containing trifunctional group chain element and preparation method thereof

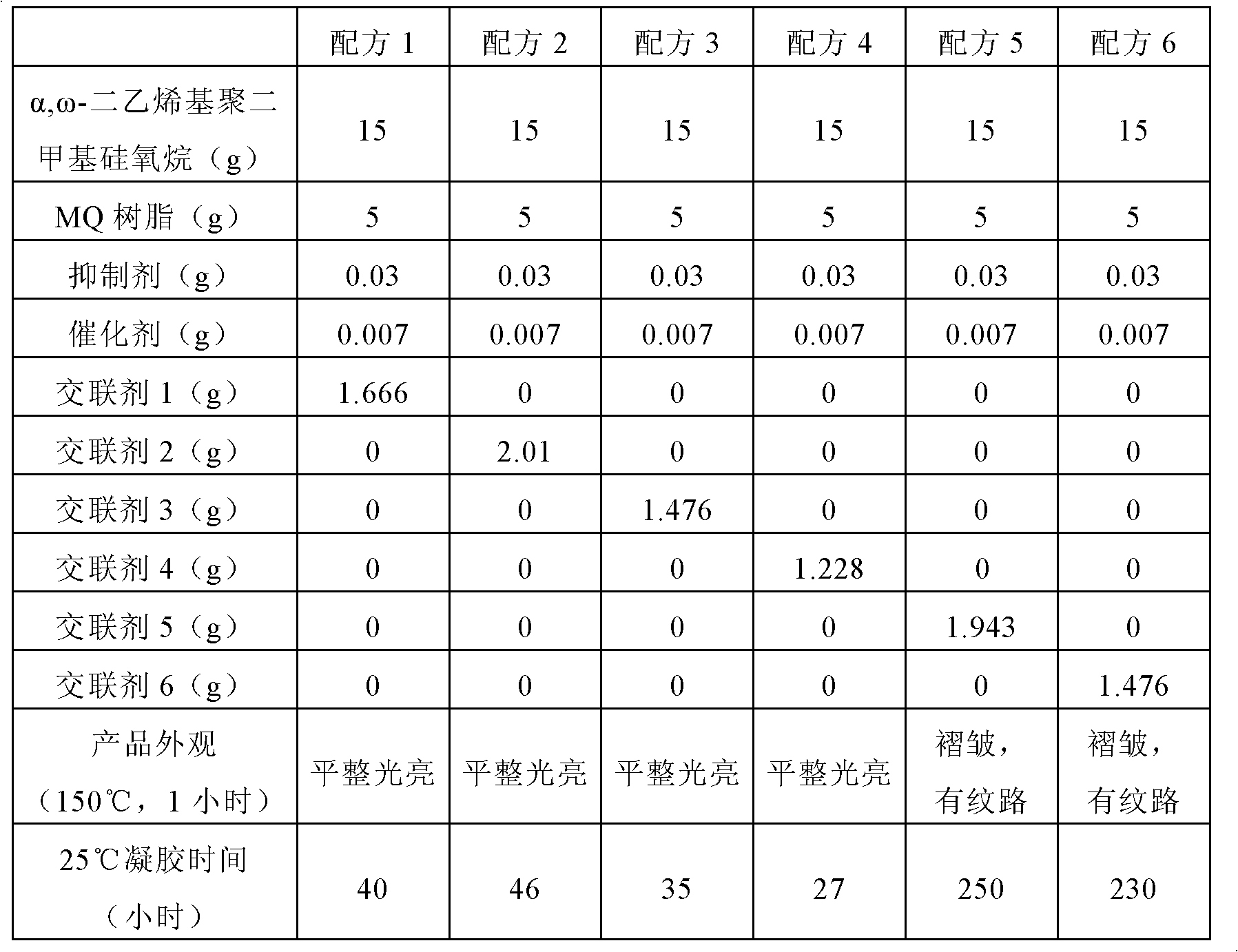

A trifunctional, silicone resin technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems such as wrinkles in addition-crosslinking reaction products, inability to achieve smooth and bright appearance, slow reaction speed, etc., to improve production efficiency and Luminous efficiency, smooth and bright appearance, fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

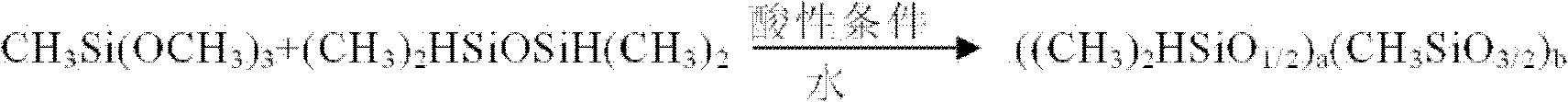

Method used

Image

Examples

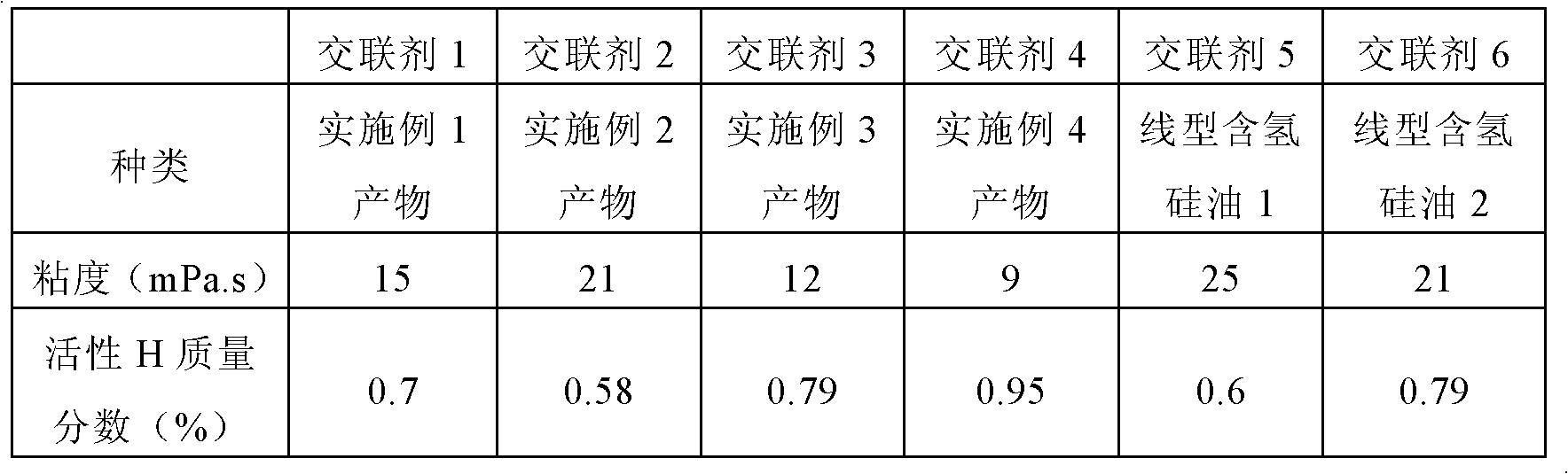

Embodiment 1

[0056] Add 136g of methyltrimethoxysilane, 67g of tetramethyldihydrodisiloxane, 70g of xylene and 0.35g of concentrated sulfuric acid into a 500ml three-necked flask, and add 35g of deionized water dropwise at 55°C under constant stirring. Run for about 50 minutes, then reflux for 1.5 hours. Change it to a distillation device, raise the temperature to 105°C, and distill out by-products. After cooling down to 45°C, 0.8g of pyridine was added and stirred for about 30 minutes to make the solution neutral. After filtering with filter paper, at 130° C., the solvent xylene and low-molecular substances were distilled off under reduced pressure using a vacuum pump to obtain 123 g of a colorless and transparent hydrogen-based silicone resin containing trifunctional chain members. The viscosity measured by the NDJ-79 rotational viscometer is 15 mPa.s, and the active H mass fraction is 0.7% as measured by the nuclear magnetic resonance method.

Embodiment 2

[0058] Add 267g of methyltriethoxysilane, 67g of tetramethyldihydrodisiloxane, 360g of toluene and 3.3g of concentrated hydrochloric acid into a 1000ml three-necked flask, and add 100g of deionized water dropwise at 85°C under constant stirring, Run for about 50 minutes, then reflux for 3.5 hours. Change to a distillation device, raise the temperature to 100°C, and distill out by-products. After cooling down to 42°C, 3.5g of sodium bicarbonate was added and stirred for about 30 minutes to make the solution neutral. After filtering with filter paper, at 120° C., the solvent toluene and low-molecular substances were distilled off using a vacuum water pump under reduced pressure to obtain 150 g of a colorless and transparent hydrogen-based silicone resin containing trifunctional chain members. Using the same method as in Example 1, its viscosity was measured to be 21 mPa.s, and the mass fraction of active H was 0.58%.

Embodiment 3

[0060] Add 102g of methyltrimethoxysilane, 67g of tetramethyldihydrodisiloxane, 10g of absolute ethanol, 140g of toluene, and 0.33g of trifluoromethanesulfonic acid into a 500ml three-necked flask. Add 40 g of deionized water for about 35 minutes, then reflux for 2 hours. Change it to a distillation device, raise the temperature to 105°C, and distill out by-products. After cooling down to 48°C, 1.5g of sodium bicarbonate was added and stirred for about 30 minutes to make the solution neutral. After filtering with filter paper, at 130° C., the solvent toluene, ethanol and low-molecular substances were distilled off using a vacuum water pump to obtain 109 g of a colorless and transparent hydrogen-based silicone resin containing trifunctional chain members. Using the same method as in Example 1, its viscosity was measured to be 12 mPa.s, and the mass fraction of active H was 0.79%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com