Gas film pressure vector control device for aerostatic bearing

A vector control and flow control valve technology, applied in the directions of hydrostatic bearings, bearings, shafts and bearings, etc., can solve the problems of lack, change, and difficulty in achieving the best working performance of gas hydrostatic bearings, and achieve the effect of vector control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

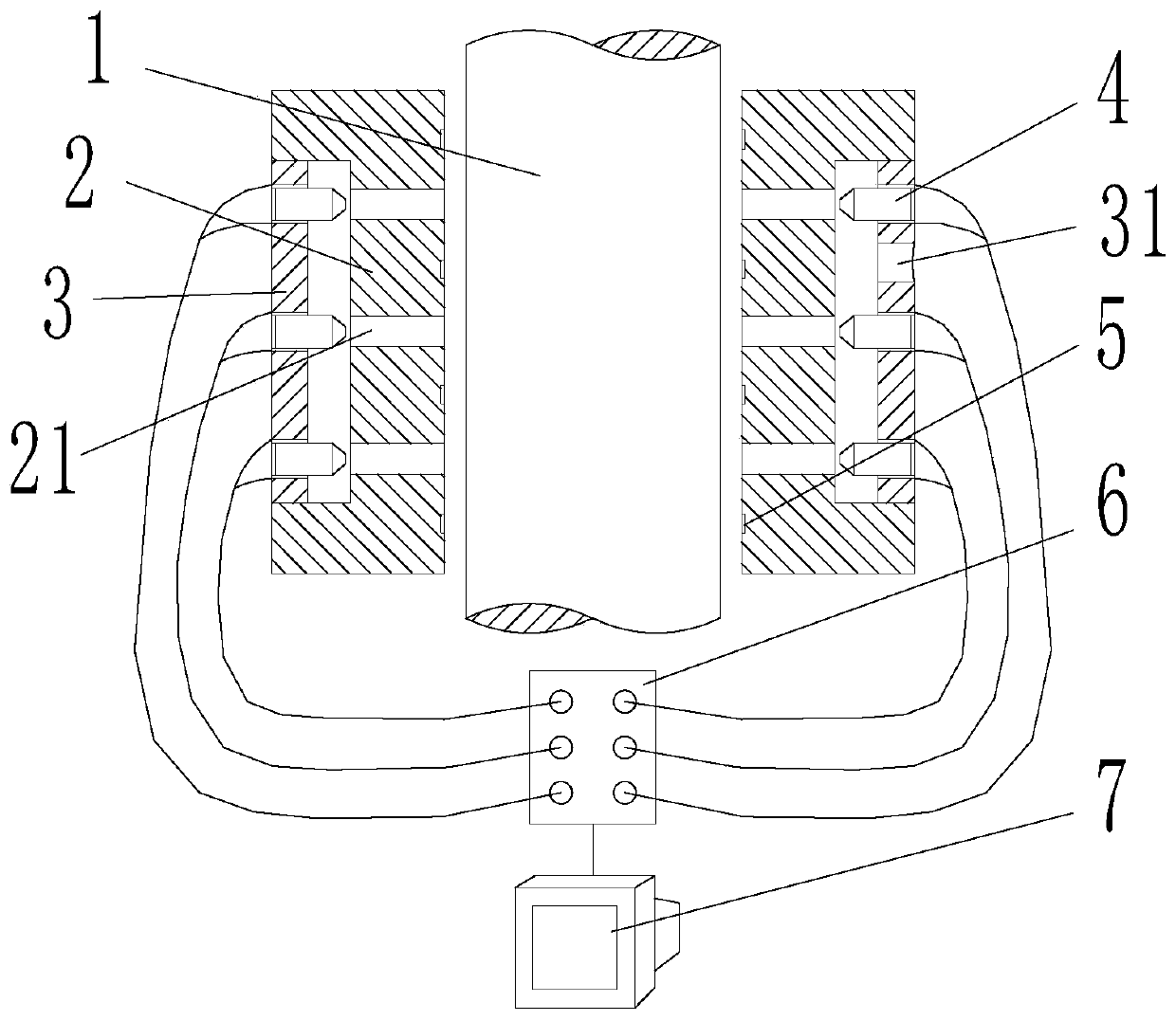

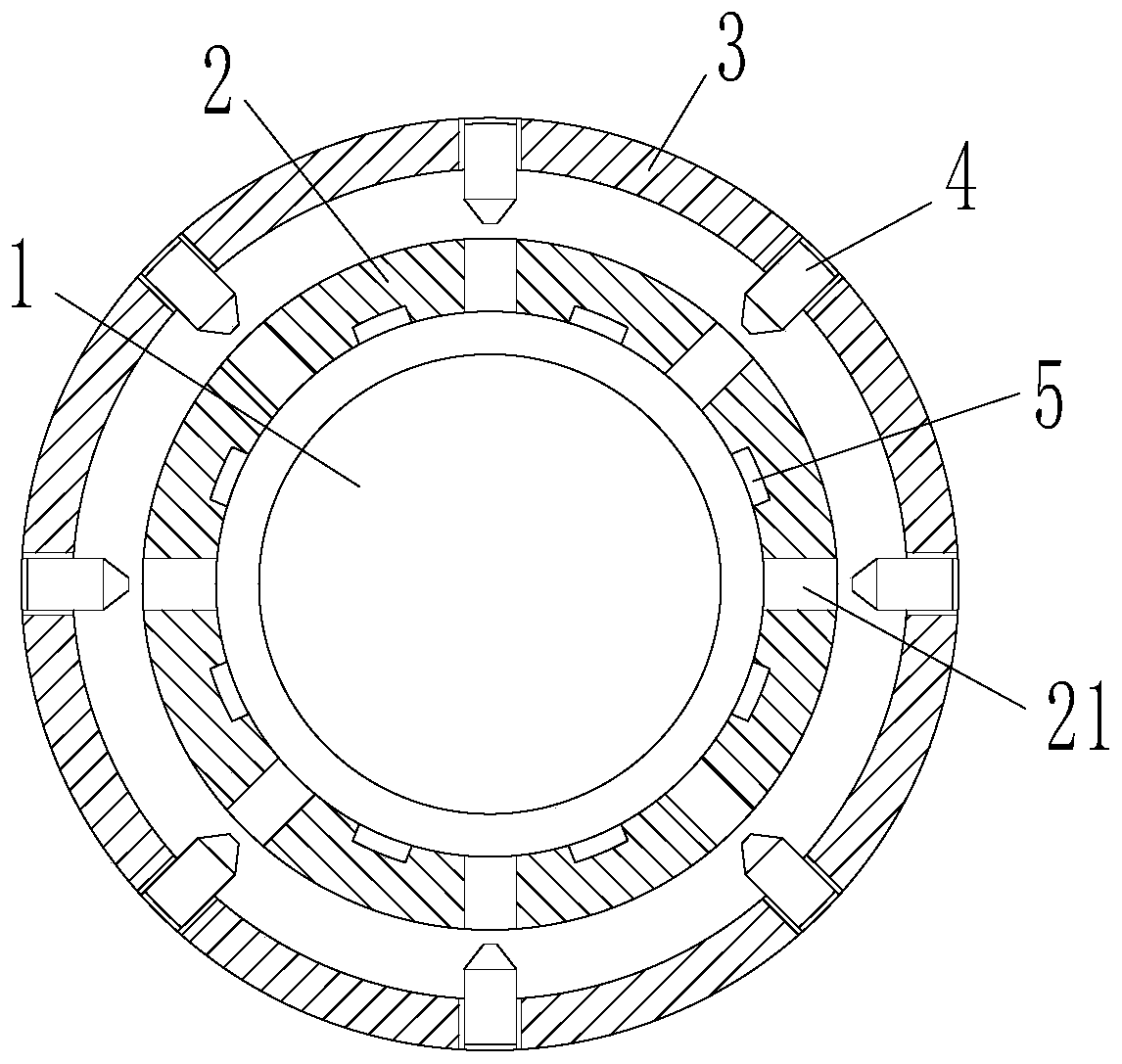

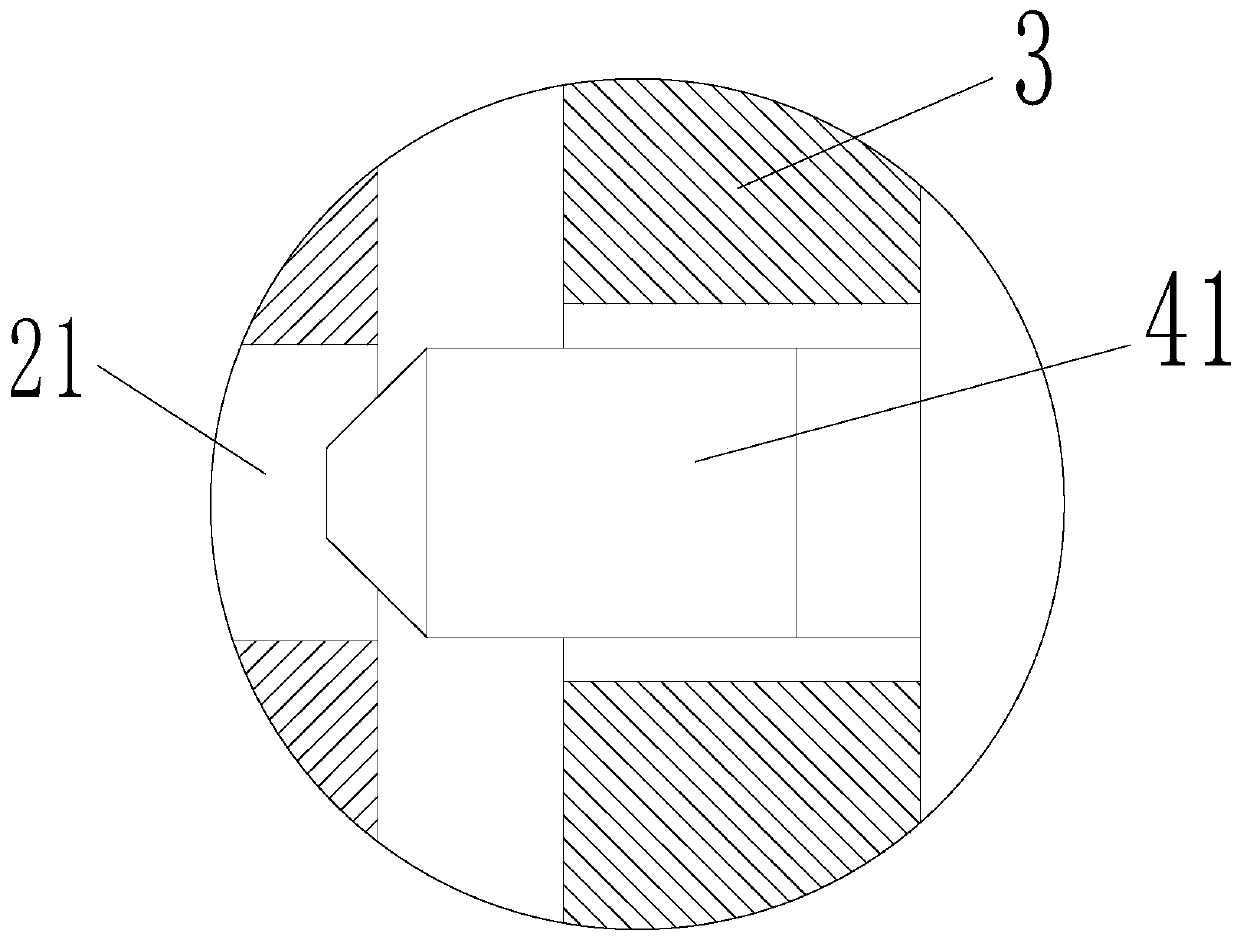

[0017] Further illustrate the present invention below in conjunction with accompanying drawing

[0018] Referring to the attached picture:

[0019] A gas film pressure vector control device for an aerostatic bearing according to the present invention includes a main shaft 1 and a bearing 2, the bearing 2 is installed outside the main shaft 1, and a gas film is formed in the gap area between the two; it is characterized in that: the bearing 2 Orifice holes 21 are evenly distributed on the top; the air outer sleeve 3 is set outside the bearing 2, and the closed area formed between the air outer sleeve 3 and the bearing 2 is an air chamber, and the orifice 21 communicates with the air film and the air chamber; A flow control valve 4 is perforated on the wall of the gas outer sleeve 3 opposite to the orifice 21, and the flow control valve 4 is coaxially arranged with the orifice 21, and the spool 41 of the flow control valve 4 adjusts the opening of the orifice 21; The air inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com