Electroless control method of compressor

A control method and compressor technology, applied in motor generator control, electronically reversing motor control, pump control, etc., can solve problems such as heavy workload, no detailed derivation of dq axis current, and cumbersome matching of compressors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

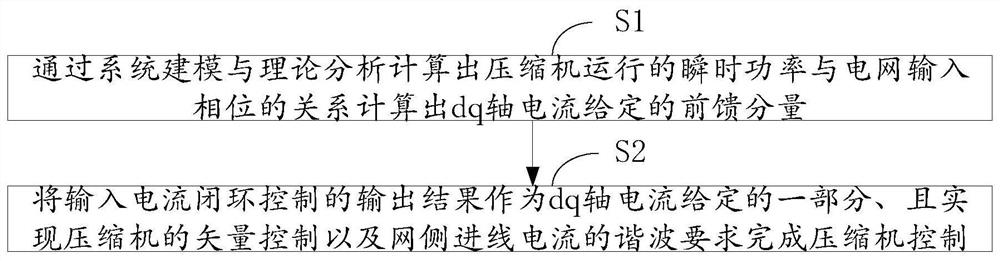

[0020] like figure 1 As shown, the flow chart of the electrolytic control method of the compressor provided by the present invention is described in detail as follows:

[0021] A strategy for generating dq-axis currents for compressor control. At this time, the bus bar is a small film capacitor, which is only a few tenths of the traditional electrolytic capacitor, and the pulsation of the bus bar is very large. However, the relevant indicators of the compressor control must first be realized, and the harmonic requirements of the incoming line current on the grid side must also be met. . Traditional dq-axis current generation strategies are no longer applicable.

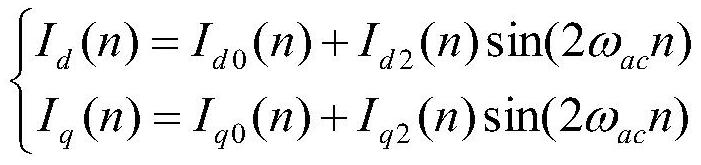

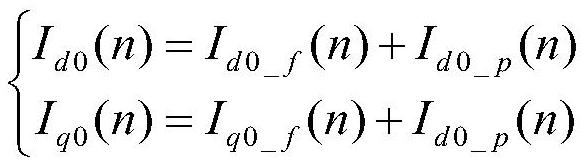

[0022] Through the combination of motor control algorithm and power factor control, firstly, through system modeling and theoretical analysis, the relationship between the instantaneous power of the compressor running and the input phase of the grid is calculated, and the feedforward components of the given dq axis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com