Plant-fiber elastic cushion and mfg. method

A technology of fiber elasticity and plant fiber, which is applied in the field of plant fiber elastic pads and production, can solve the problems of unsatisfactory air permeability, needs to be improved, and insufficient elasticity of palm fiber elastic materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

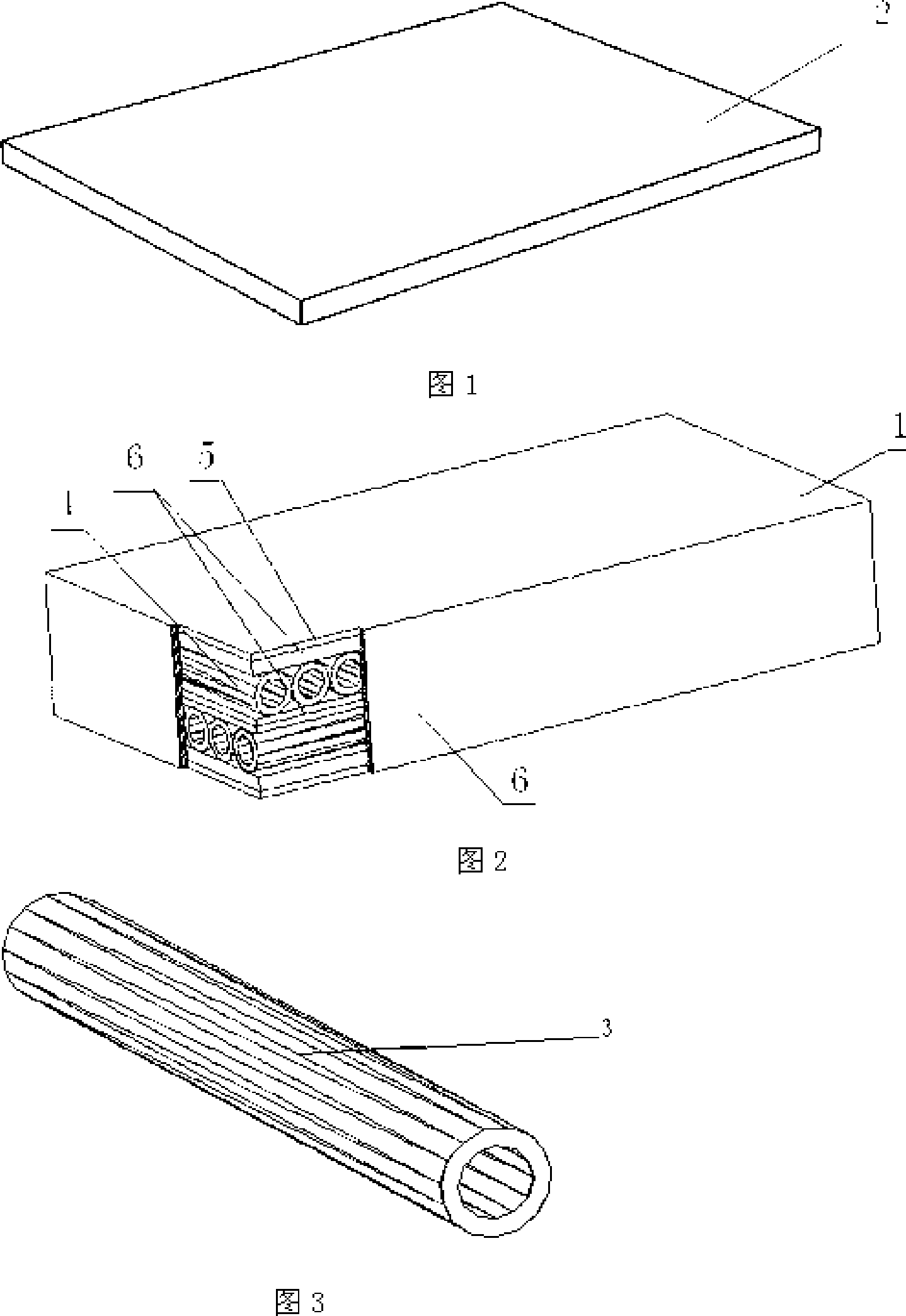

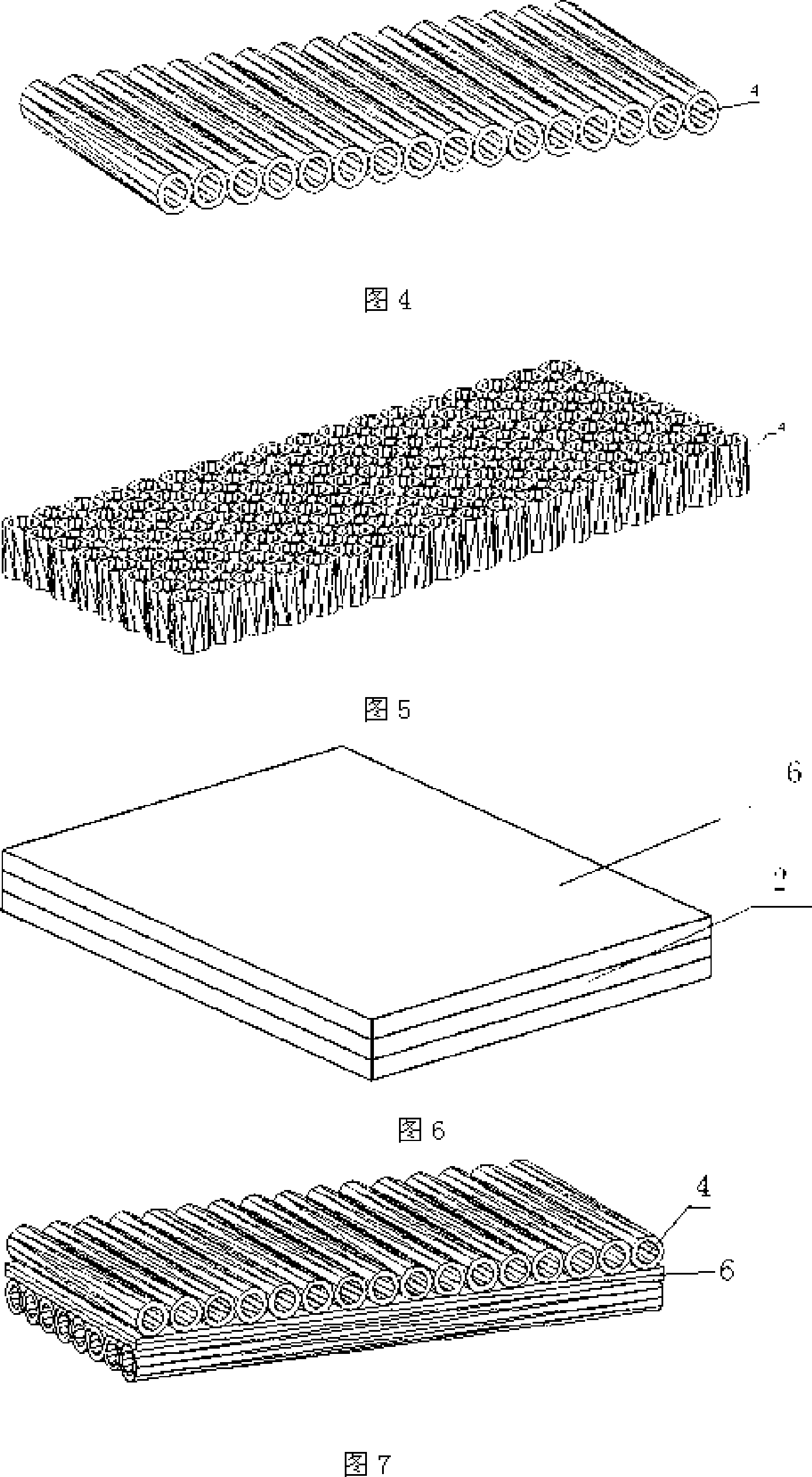

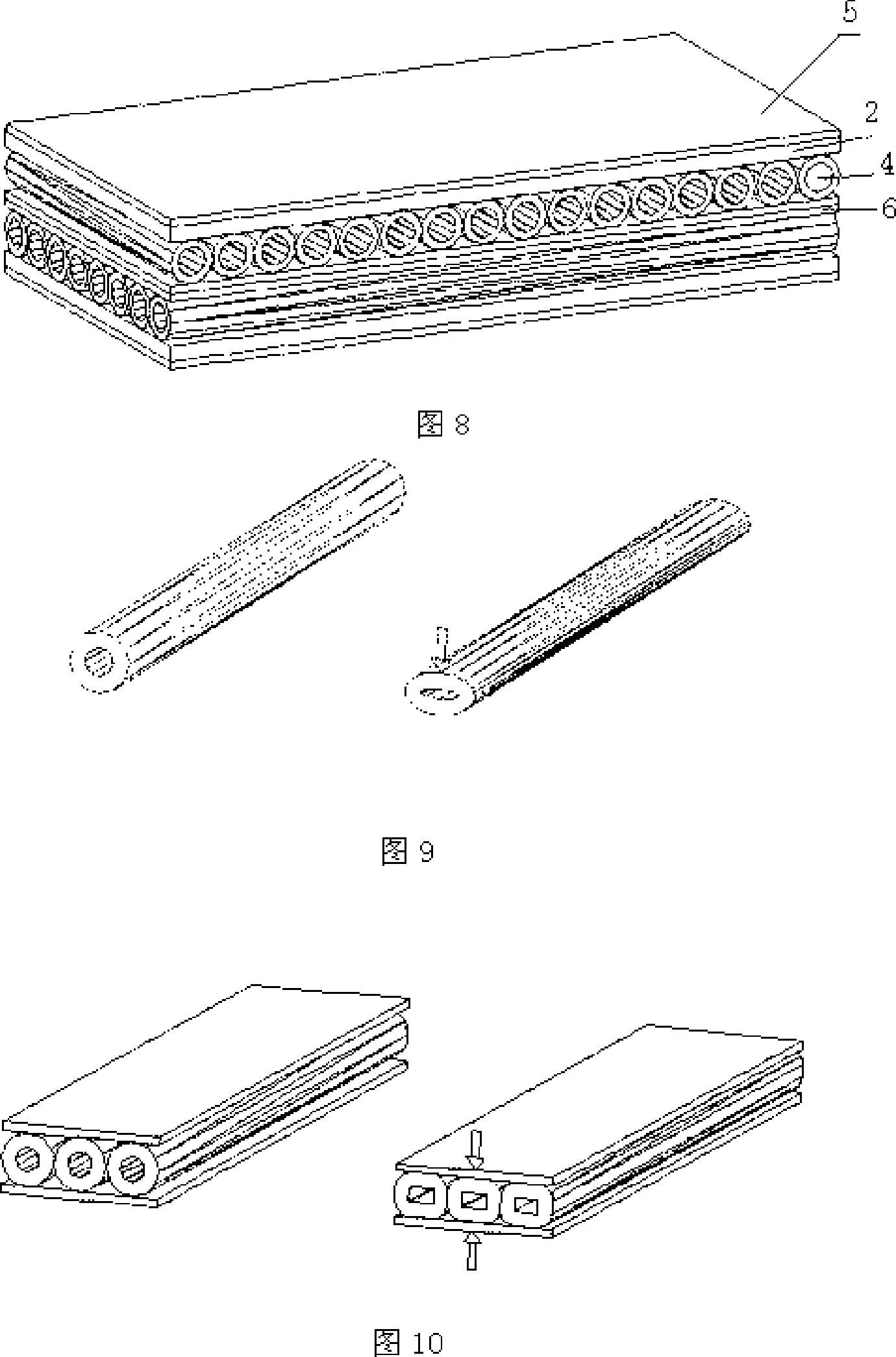

Embodiment 1

[0019] Embodiment 1 of the present invention: first obtain the fiber elastic sheet 2 according to the prior art, add sulfur into the natural latex used in the fiber elastic sheet 2 as a vulcanizing agent, and roll the fiber elastic sheet 2 into a fiber elastic roll Roll 3, and then arrange the elastic rolls 3 horizontally, glue and fix them together to make an elastic roll layer 4, and use one or more fiber elastic sheets 2 to make a fiber plastic layer 6. The prepared elastic roll layer 4 and the fiber plastic layer 6 are hot-pressed and fixed together, the temperature for hot-pressing is 60-140°C, the hot-pressing time is 15-50 minutes, and then vulcanization and setting are carried out. The method of vulcanization and setting is as follows: Put the fiber elastic mat 1 into an environment with a temperature of 80-130° C. and a pressure of 0.2-0.4 MPa for vulcanization and setting for 20-90 minutes.

[0020] In order to improve the elasticity of the roll, the fiber elastic ro...

Embodiment 2

[0025] Embodiment 2 of the present invention: first obtain the fiber elastic sheet 2 according to the prior art, add sulfur into the natural latex used in the fiber elastic sheet 2 as a vulcanizing agent, and roll the fiber elastic sheet 2 into a fiber elastic roll tube 3, and then the elastic rolls 3 are arranged longitudinally, bonded and fixed together, and made into an elastic roll layer 4, and one layer of the elastic roll layer 4 and the fiber plastic layers 6 of the upper and lower layers 6 are heat-pressed and fixed together, The hot-pressing temperature is 140°C, the hot-pressing time is 15 minutes, and then vulcanization and setting are carried out. The method of vulcanization and setting is to put the fiber elastic mat 1 into an environment with a temperature of 130°C and a pressure of 0.2Mpa for 20 minutes for vulcanization and setting.

[0026] In order to ensure the comfort of the elastic pad 1, the fiber elastic sheet material on the upper surface and the lower s...

Embodiment 3

[0028] Embodiment 3 of the present invention: firstly obtain the fiber elastic sheet 2 according to the prior art, roll the fiber elastic sheet 2 into the fiber elastic reel 3, then arrange the elastic reel 3 horizontally, glue and fix them together, The elastic roll layer 4 is made, and the elastic roll layer 4 is vulcanized and set. The vulcanization set temperature is 90°C, the pressure is 0.2Mpa, and the time is 30 minutes. Then the vulcanized elastic roll layer 4 and the fiber plastic layer 6 are hot-pressed and fixed together at a temperature of 100° C. for 35 minutes, and then vulcanized and shaped again at a temperature of 120° C. Vulcanize and set for 40 minutes in an environment with a pressure of 0.2Mpa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com