Anatomical shoe insert assembly

anatomical shoe insert and shoe technology, applied in the direction of uppers, insoles, bootlegs, etc., can solve the problems of inability to deliver, lose the effect, and the wearer of these shoes typically compromises on comfort, so as to prevent inconsistencies in assembly, improve the distribution of pressure and comfort of shoes, and lock in the anatomical shape of the shoe.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

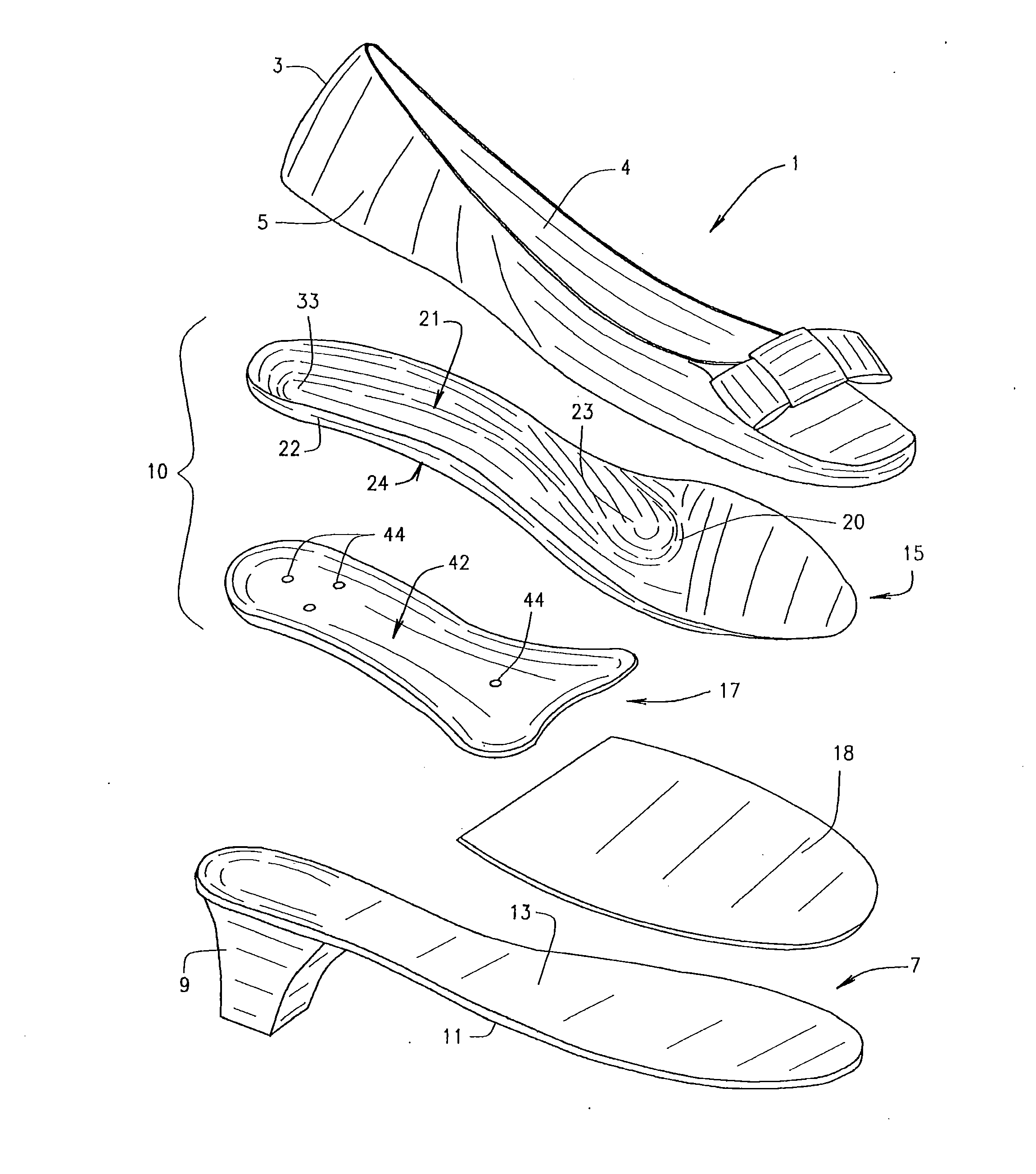

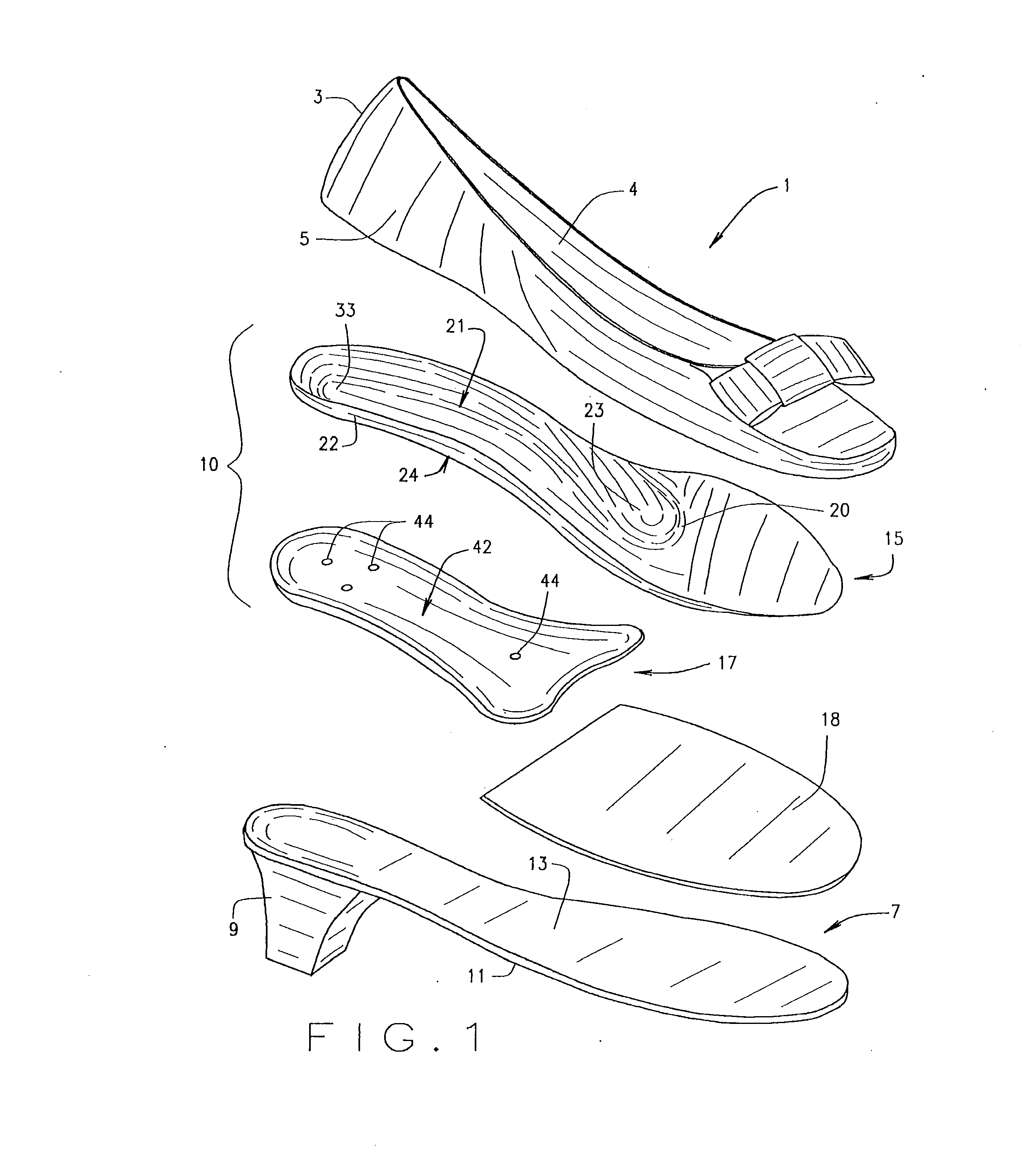

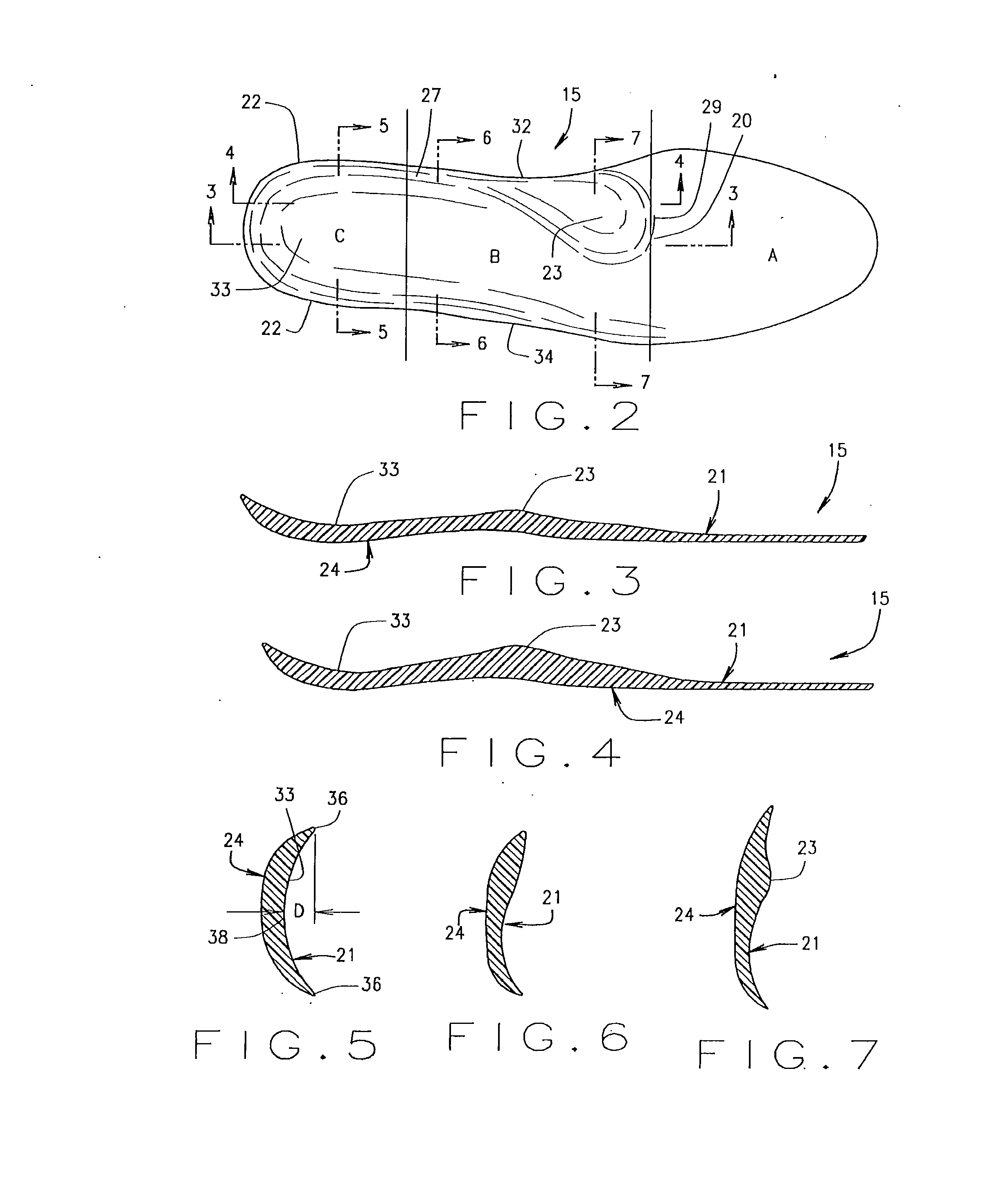

[0027]In the present invention, an insert assembly is provided which improves comfort and can be installed in any type of shoe. For purposes of this invention, it is to be understood that high-heeled shoes include all footwear having a heel which elevates the heel of a person's foot above the midfoot and / or forefoot portions of a wearer's foot. The benefits of the present invention are achieved when a raised area is positioned in a shoe to underlie the medial arch area and a concaved area is formed to underlie the heel area. Preferably, the insert assembly of the present invention functions as the insole board and / or sockliner of a high-heeled footwear. Although the present insert assembly will be disclosed in connection with a typical high-heeled shoe, those skilled in the art will recognize that any type of shoe can be used with the present insert assembly without departing from the spirit and scope of the present invention.

[0028]The reference numeral 1 designates generally a shoe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com