Elastic ring type damper with metal rubber

A metal rubber, elastic ring technology, applied in the direction of rotational vibration suppression, etc., can solve problems such as the inability to produce a squeeze oil film, and the rotor is difficult to pass the critical operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

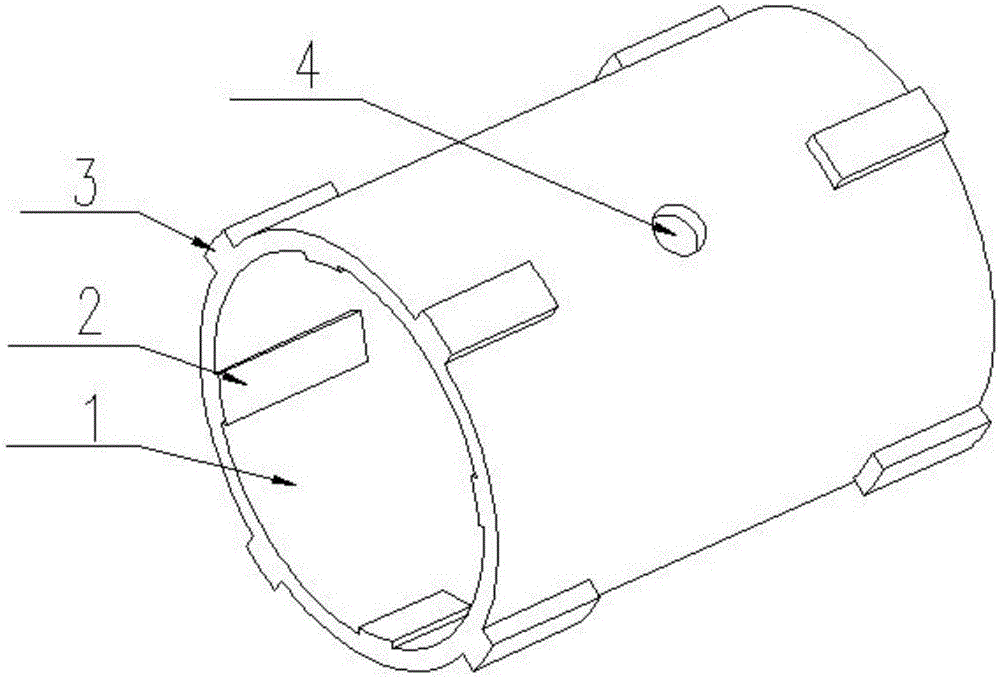

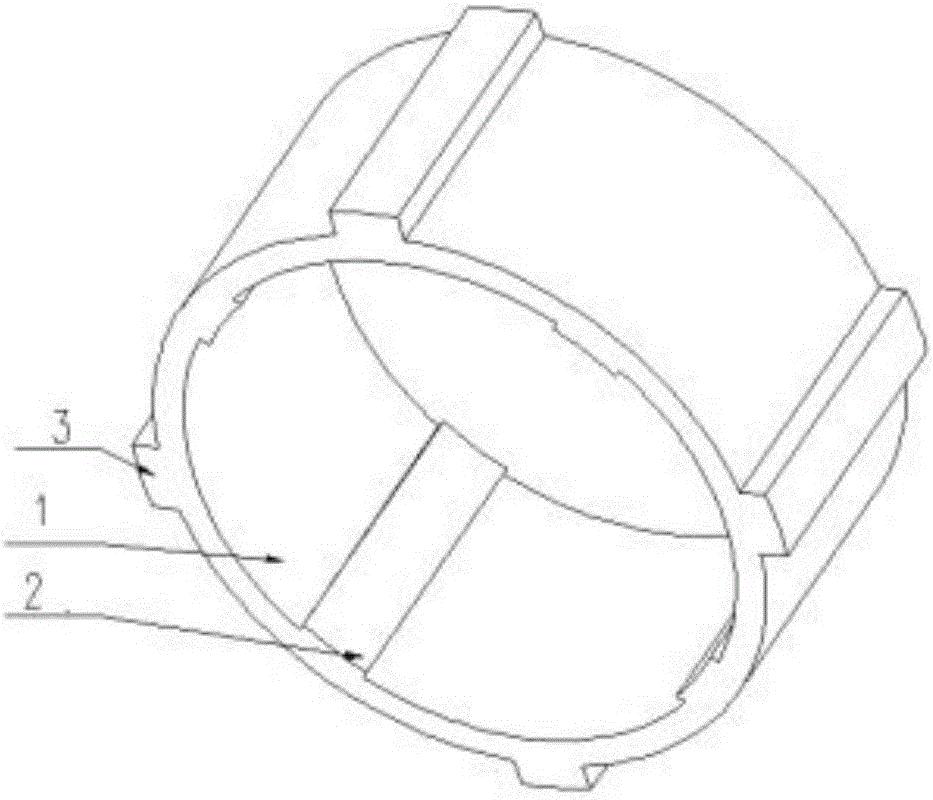

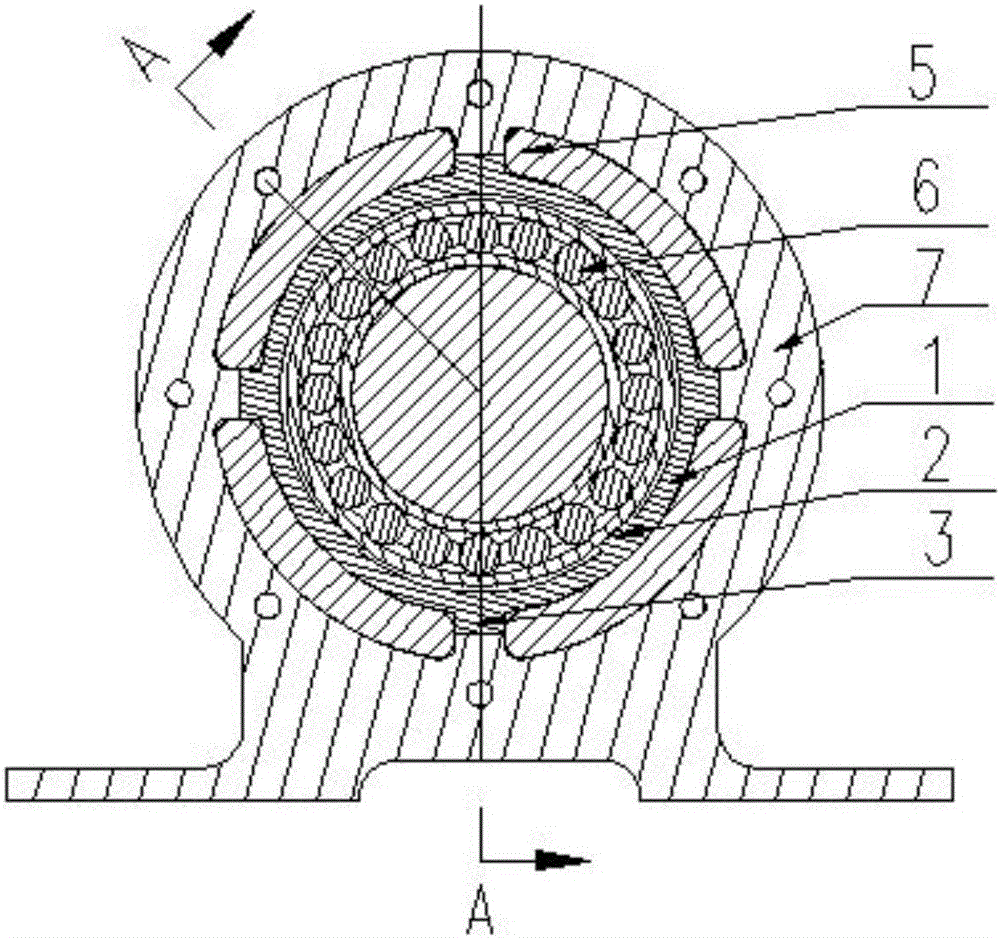

[0018] refer to Figure 1-a , Figure 1-b , Figure 2-a , Figure 2-b , Figure 2-c , an elastic ring damper with metal rubber, including an elastic ring 1 connected to the outside of the rolling bearing 6, the elastic ring 1 is a thin-walled cylindrical structure, and the inner and outer walls of the elastic ring 1 are respectively provided with regular rectangular raised inner bosses 2 and the outer boss 3, the inner boss 2 and the outer boss 3 are evenly distributed along the circumferential direction of the elastic ring 1, and the inner boss 2 and the outer boss 3 are alternately distributed, that is, the inner boss 2- --Outer Boss 3----Inner Boss 2---Outer Boss 3 reciprocates, every two outer Bosses 3 are filled with metal rubber 5, metal rubber 5 is formed by winding metal wire and cold stamping , the length and width parameters of the metal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com