High-temperature-resistant mechanical sealing device

A mechanical sealing device and high temperature resistant technology, which is applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems of auxiliary seal failure, limited effect, and influence of sealing ring sealing performance, and reduce mechanical deformation and thermal deformation , improve efficiency and service life, and prevent seal leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

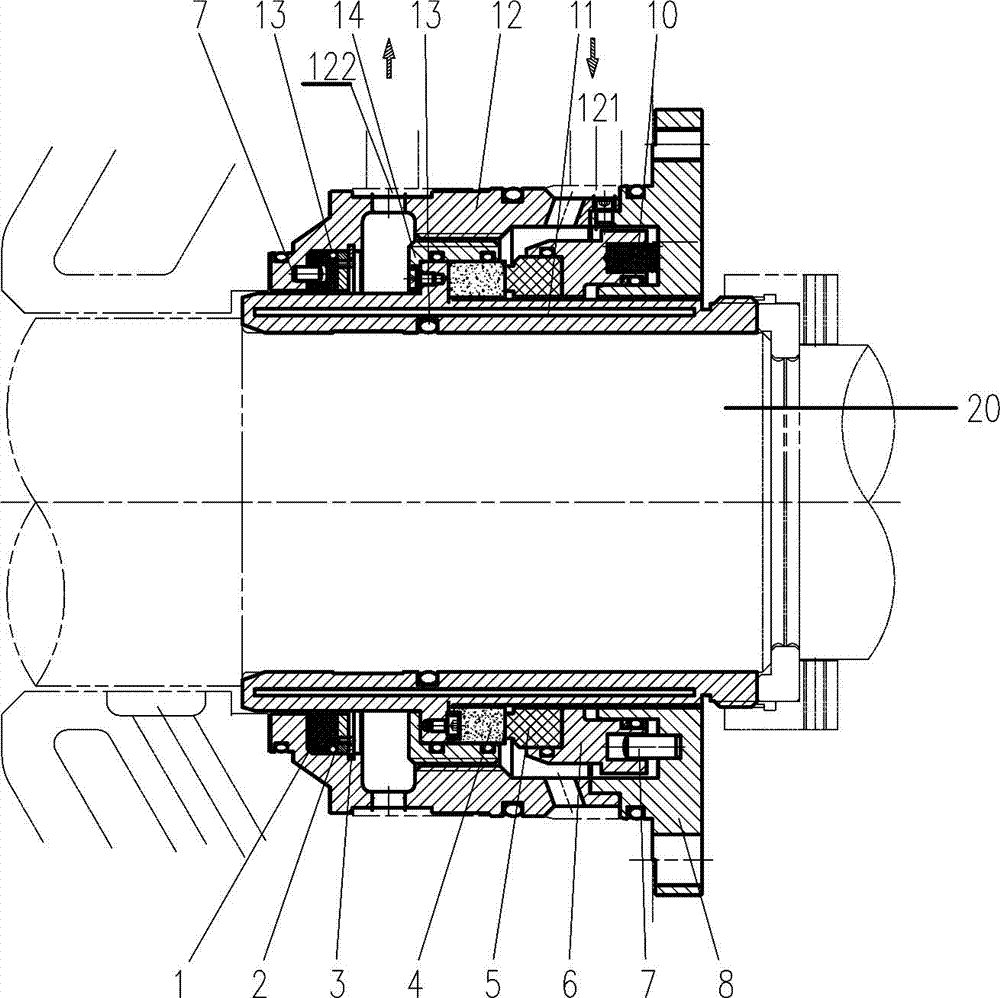

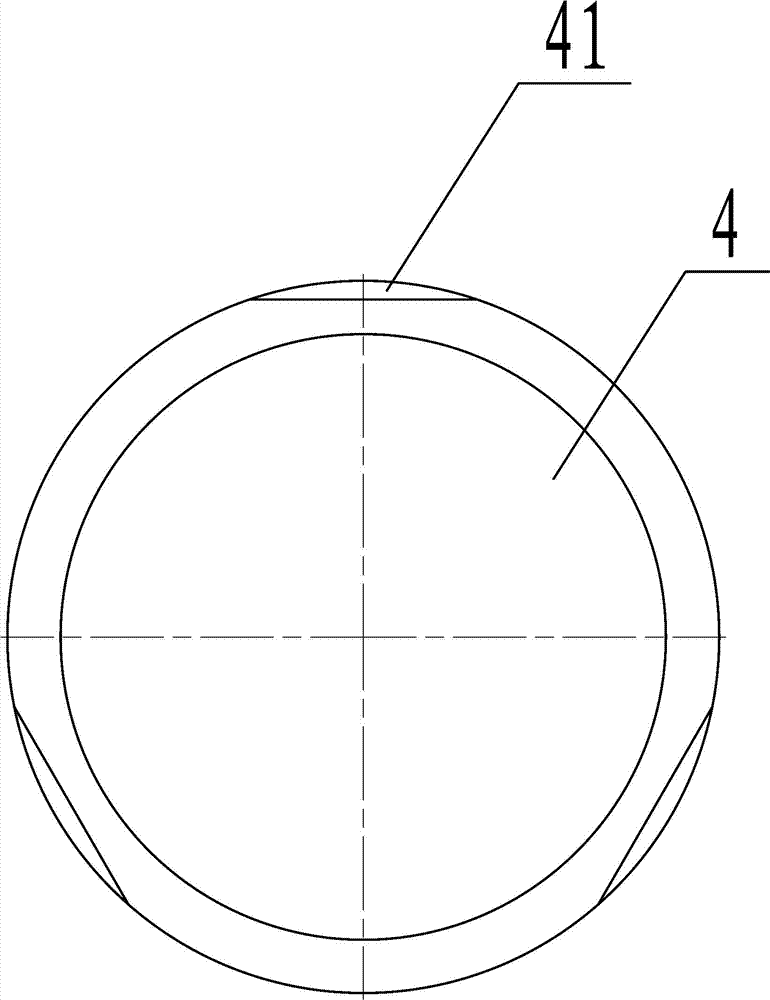

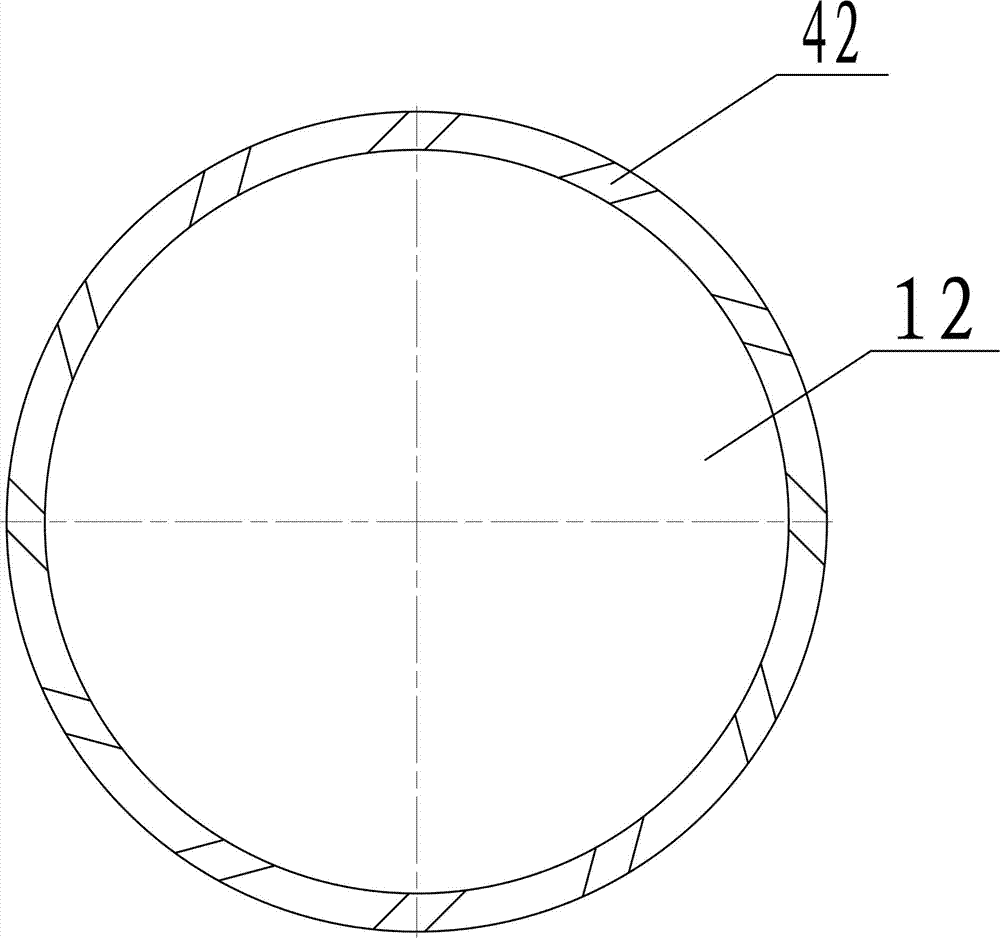

[0037] A high-temperature-resistant mechanical seal device, including a self-centering throttle ring 1, a pressure plate 2, a snap ring 3, a moving ring 4, a static ring 5, a static ring seat 6, a cylindrical pin 7, a gland 8, a compression spring 10, and a vacuum Shaft sleeve 11, outer flow guide sleeve 12, O-ring 13, inner flow guide sleeve 14 and rotating shaft 20, such as Figure 1 ~ Figure 3 As shown, the specific structure is:

[0038] The vacuum bushing 11 is a hollow structure, and the inner cavity of the vacuum bushing 11 is in a high vacuum state not higher than 0.01KPa. Ring 13, the outer surface of the vacuum bushing 11 is provided with an annular step;

[0039]The inner diversion sleeve 14 is a cylindrical shape with the bottom surface closed and one end open. The inner diversion sleeve 14 is sleeved on the vacuum bushing 11 through the through hole opened on the bottom surface, and the inner diversion sleeve 14 is fixed on the annular step of the vacuum bushing ...

Embodiment 2

[0058] A high-temperature-resistant mechanical seal device, including a self-centering throttle ring 1, a pressure plate 2, a snap ring 3, a moving ring 4, a static ring 5, a static ring seat 6, a cylindrical pin 7, a gland 8, a compression spring 10, and a vacuum Shaft sleeve 11, outer flow guide sleeve 12, O-ring 13, inner flow guide sleeve 14, O-ring 13 and rotating shaft 20, also includes positioning block 9, such as Figure 4 As shown, the specific structure is: one end of the positioning block 9 is sleeved in the positioning groove on the outer wall of the vacuum bushing 11, and the inner end surface of the positioning block 9 is detachably fixed to the flange chassis of the gland 8. Other structures are all the same as in Embodiment 1.

[0059] When this embodiment is in use, when it is not running, use the positioning block 9 to keep the mutual position between the gland 8 and the vacuum bushing 11 fixed, so that the positions of the remaining parts are kept fixed, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com