Environmental-friendly heavy metal stabilizer and application method thereof

A heavy metal stabilizer, an environmentally friendly technology, applied in chemical instruments and methods, applications, agriculture, etc., can solve the problems of limited practical use, soil hardening, etc., and achieve poor arableability, reduced toxicity and bioavailability, Effects on reducing risks to the environment and human health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

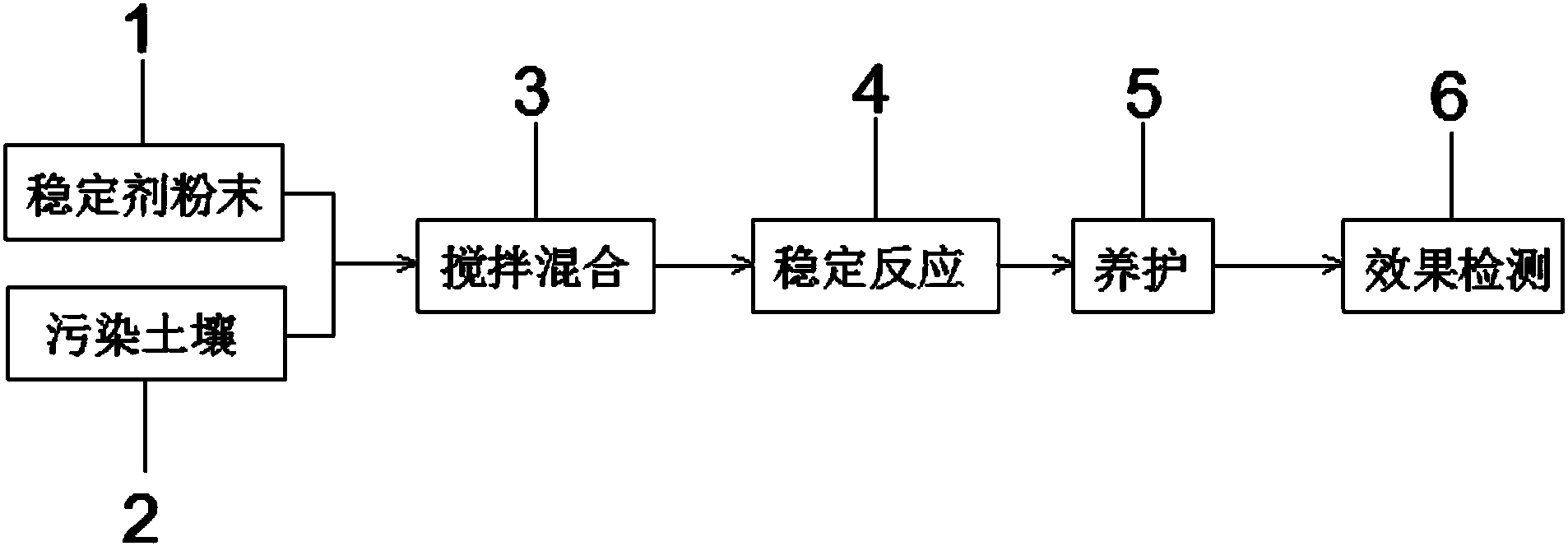

Method used

Image

Examples

Embodiment 1

[0039] An environment-friendly heavy metal stabilizer, the preparation method includes the following material components in terms of parts by mass: 40 parts of clay minerals, 17 parts of adsorption materials, 10 parts of heavy metal chelating agents, 4 parts of heavy metal precipitants, and alkaline regulators 10 parts, the attapulgite needs to be activated at 220-350°C for 20-30 minutes before use, wherein the heavy metal precipitant is selected from hydroxyapatite, and the alkaline regulator is lime powder, and the lime powder is passed through 200 sieves used later.

[0040] The clay minerals include 25 parts of attapulgite and 15 parts of attapulgite.

[0041] The adsorption material comprises 15 parts of peanut shell powder and 2 parts of nanometer gamma-alumina, and the particle size of the peanut shell powder is 2-3 mm.

[0042] The heavy metal chelating agent comprises 5 parts of sodium lignosulfonate and 5 parts of sodium humate.

[0043] The heavy metal ions in the h...

Embodiment 2

[0055] An environment-friendly heavy metal stabilizer, the preparation method includes the following material components in terms of parts by mass: 46 parts of clay minerals, 20 parts of adsorption materials, 16 parts of heavy metal chelating agents, 6 parts of heavy metal precipitants, and alkaline regulators 12 parts, the attapulgite needs to be activated at 220-350°C for 20-30 minutes before use, wherein the heavy metal precipitant is selected from hydroxyapatite, and the alkaline regulator is lime powder, and the lime powder is passed through 200 sieves used later.

[0056] The clay minerals include 28 parts of attapulgite and 18 parts of attapulgite.

[0057] The adsorption material includes 17 parts of peanut shell powder and 3 parts of nanometer gamma-alumina, and the particle size of the peanut shell powder is 2-3 mm.

[0058] The heavy metal chelating agent comprises 7 parts of sodium lignosulfonate and 7 parts of sodium humate.

[0059] The heavy metal ions in the ...

Embodiment 3

[0066] An environment-friendly heavy metal stabilizer, the preparation method includes the following material components in terms of parts by mass: 50 parts of clay minerals, 24 parts of adsorption materials, 18 parts of heavy metal chelating agents, 8 parts of heavy metal precipitants, and alkaline regulators 15 parts, the attapulgite needs to be activated at 220-350°C for 20-30 minutes before use, wherein the heavy metal precipitant is selected from hydroxyapatite, and the alkaline regulator is lime powder, and the lime powder is passed through 200 sieves used later.

[0067] The clay minerals include 30 parts of attapulgite and 20 parts of attapulgite.

[0068] The adsorption material includes 20 parts of peanut shell powder and 4 parts of nanometer gamma-alumina, and the particle size of the peanut shell powder is 2-3 mm.

[0069] The heavy metal chelating agent comprises 8 parts of sodium lignosulfonate and 10 parts of sodium humate.

[0070] The heavy metal ions in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com