Single-crystal and poly-crystal flocking equipment

A kind of equipment and acid texturing technology, which is applied in the field of monocrystalline and polycrystalline texturing equipment, can solve the problem that the monocrystalline silicon wafer texturing or polycrystalline silicon wafer texturing cannot be realized at the same time, and achieve the effect of stable process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

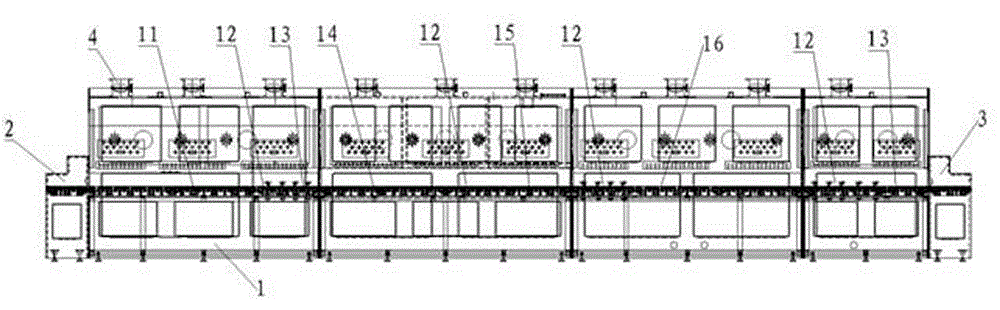

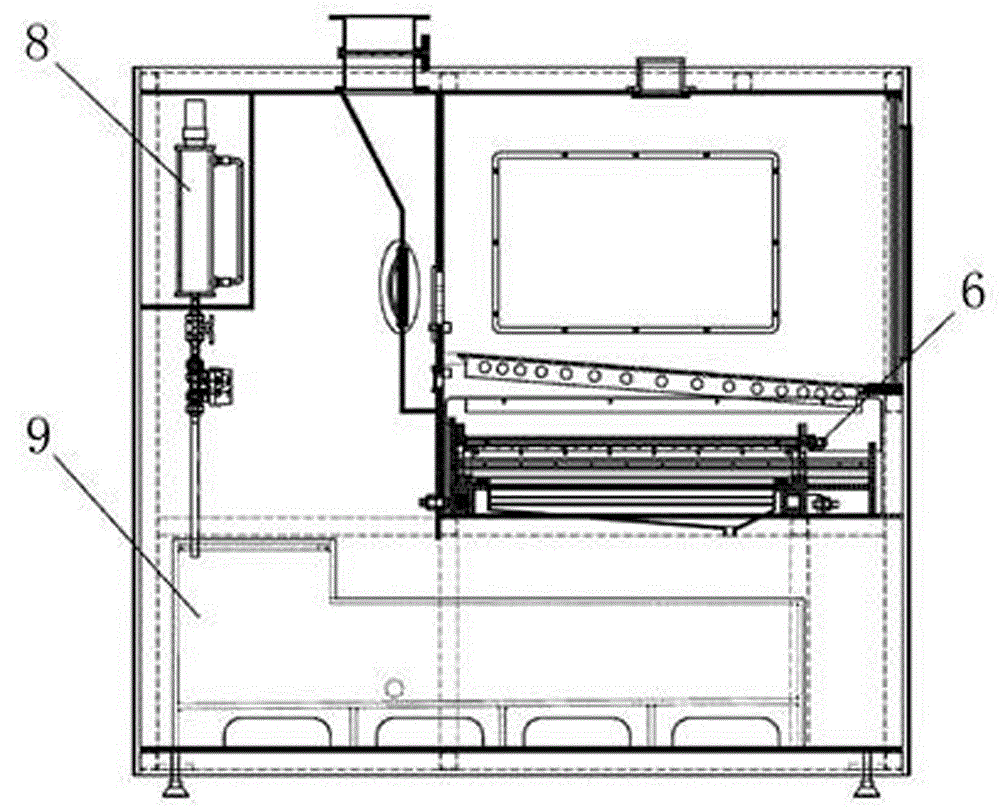

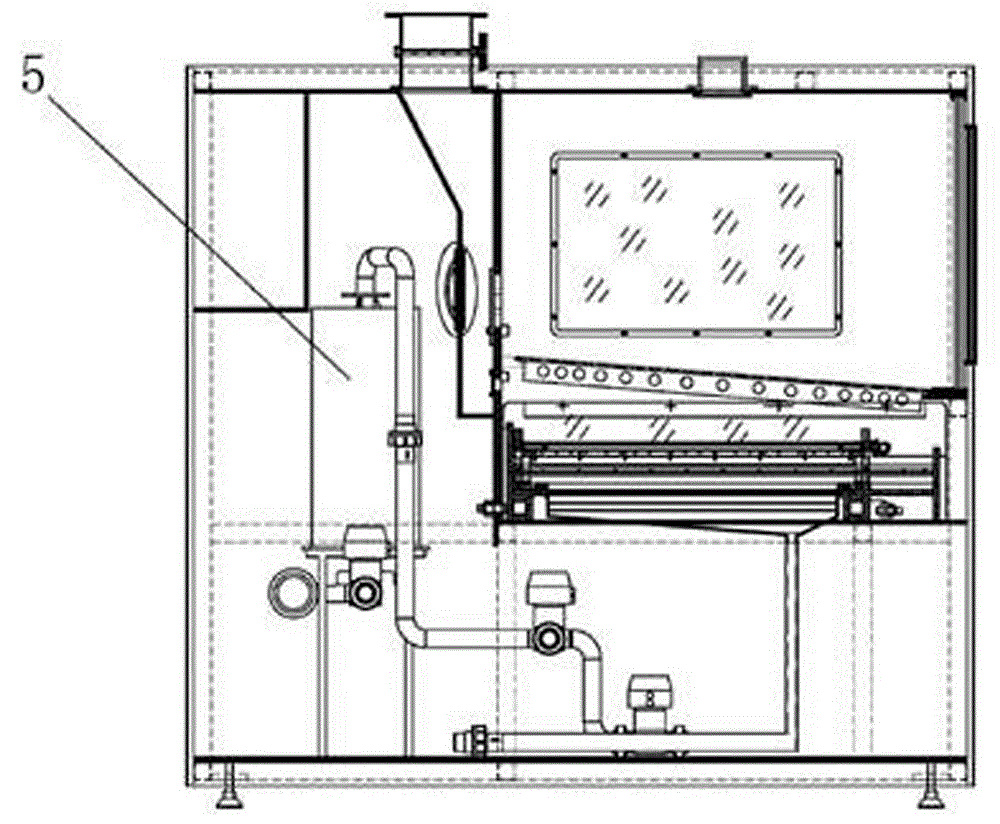

[0035] Such as figure 1 , 2 As shown, the single-polycrystalline texturing equipment proposed by the present invention includes: equipment main body 1, each station, transmission device 6 and control system arranged on the equipment main body in sequence from front to back, and a feeding platform is provided at both ends of the equipment 2 and the blanking table 3, the top of the equipment main body 1 is provided with an exhaust system 4. Each station is sequentially set up as soaking acid texturing station 11, spraying washing station 12, drying station 13, spraying alkali texturing station 14, spraying washing station 12, and soaking alkali treatment station 15. Spray washing station 12, acid treatment station 16, spray washing station 12, drying station 13. When in use, the silicon wafer 7 is placed horizontally on the feeding table 2. The feeding table 2 has an automatic straightening device and a drip protection device. The sheets are sequentially transferred to each s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com